Mudcake Adhesion Lubricants for Water-Based Drilling Fluids

A water-based drilling fluid and lubricant technology, applied in the field of mud cake adhesion lubricants, can solve the problems of mud cake adhesion and poor lubrication ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

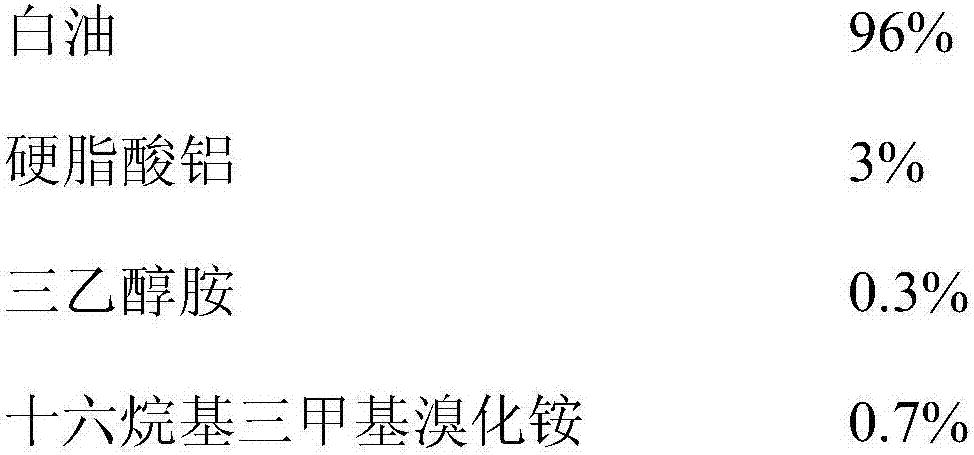

Embodiment 1

[0047] Mix the materials according to the following formula (calculated by mass percentage), and heat and stir at 120° C. for 15 minutes until the solids are completely dissolved to obtain mud cake adhesive lubricant for water-based drilling fluid.

[0048] White oil 96.2%

[0049] Aluminum stearate 3.1%

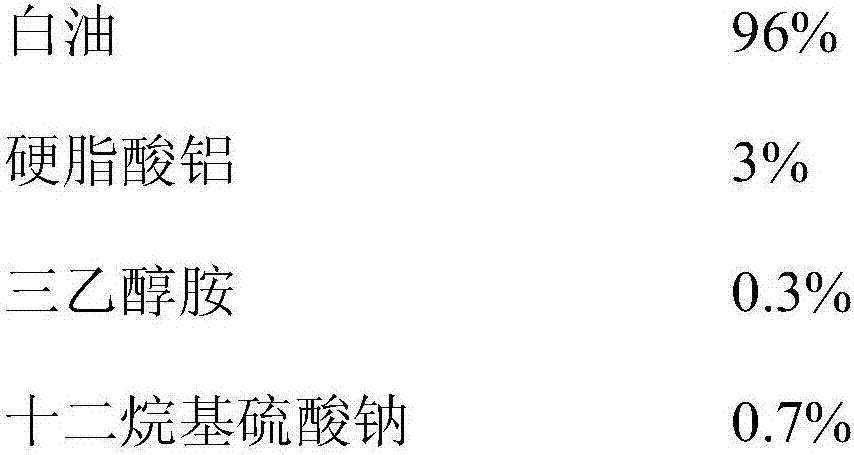

Embodiment 2

[0052] Mix the materials according to the following formula (calculated by mass percentage), and heat and stir at 120° C. for 15 minutes until the solids are completely dissolved to obtain mud cake adhesive lubricant for water-based drilling fluid.

[0053]

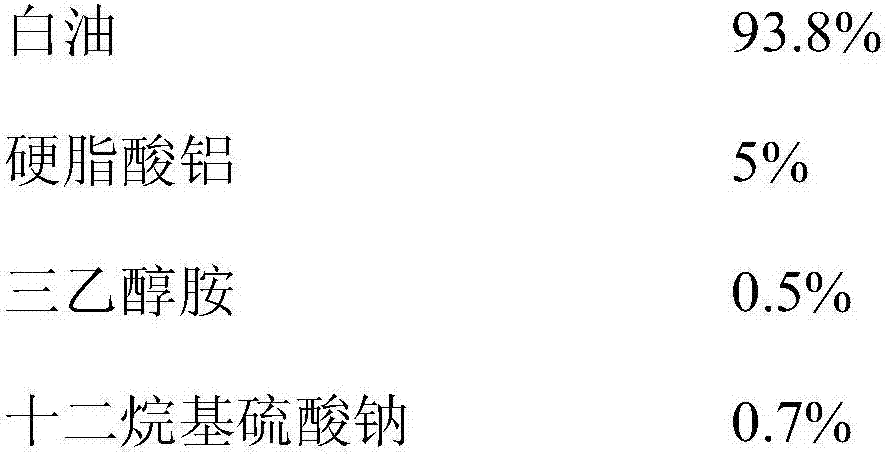

Embodiment 3

[0055] Mix the materials according to the following formula (calculated by mass percentage), and heat and stir at 120° C. for 15 minutes until the solids are completely dissolved to obtain mud cake adhesive lubricant for water-based drilling fluid.

[0056]

[0057] In this embodiment, if triethanolamine is not added, the lubricant will be jelly-like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com