Compaction hammer and dynamic compaction machine with compaction hammer

A technology of dynamic compactor and rammer, which is applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of uneven ground, poor quality of foundation compaction, and cannot effectively reduce the hidden danger of rammer safety, so as to improve safety. The effect of preventing splashes from hurting people and reducing environmental noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] In the present invention, unless otherwise stated, the directions referred to are all relative to the state of use of the rammer, the end connected to the sling is "up", and the end that touches the ground is "down".

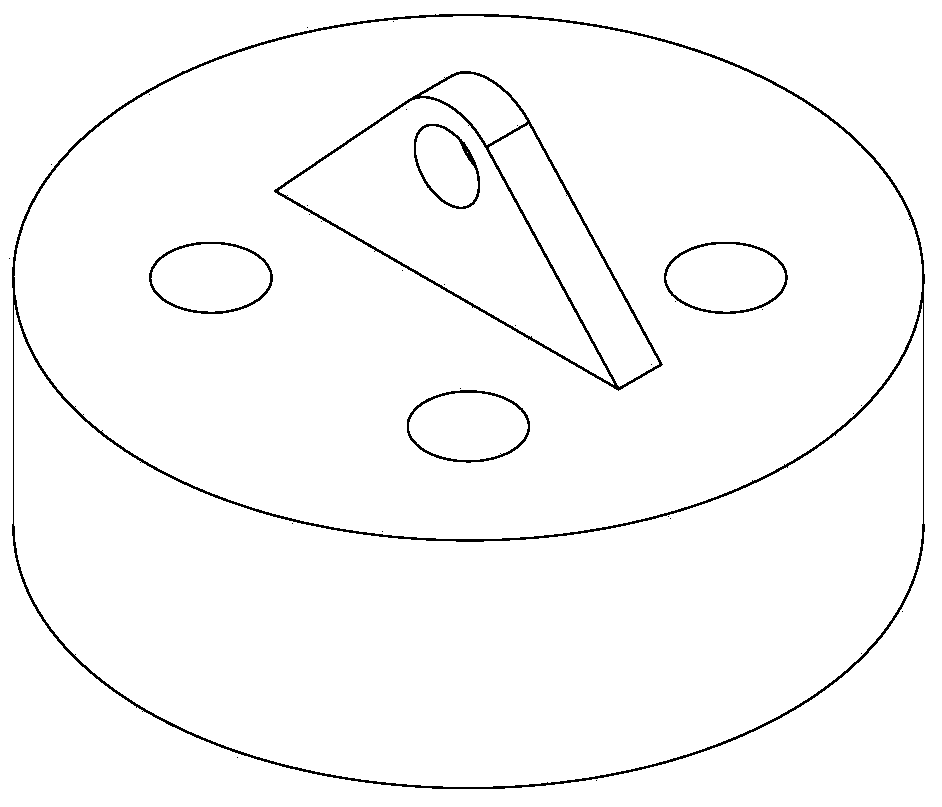

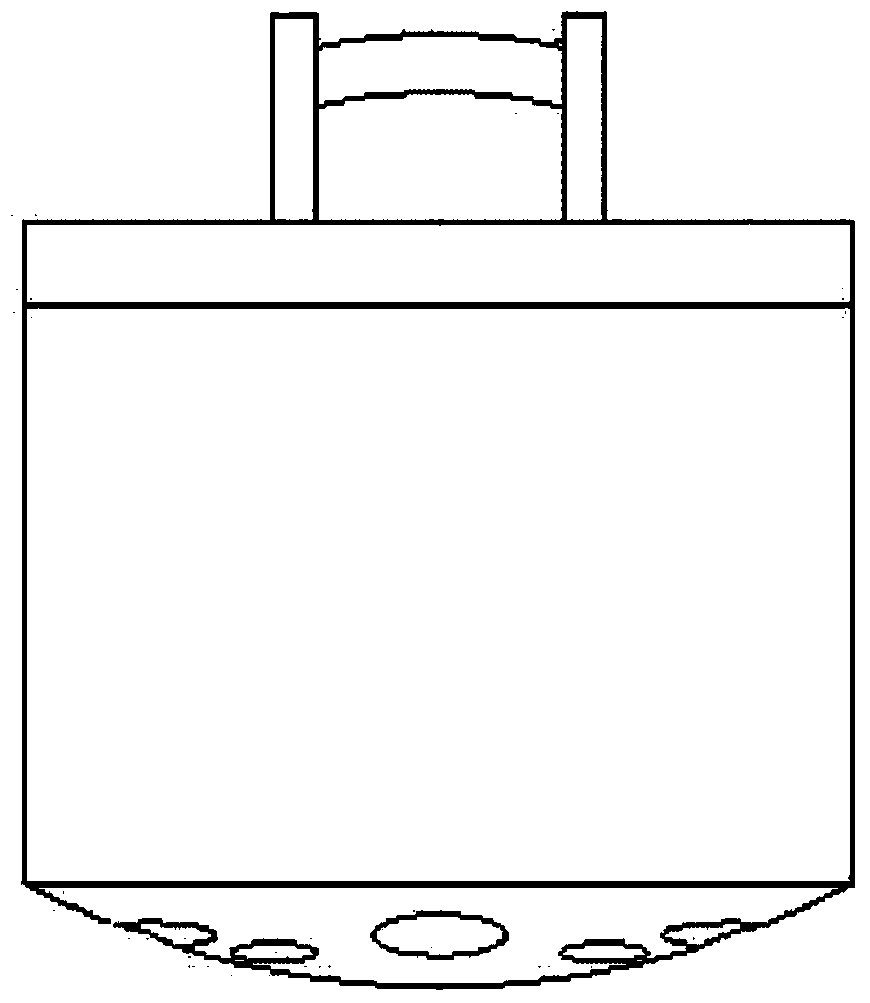

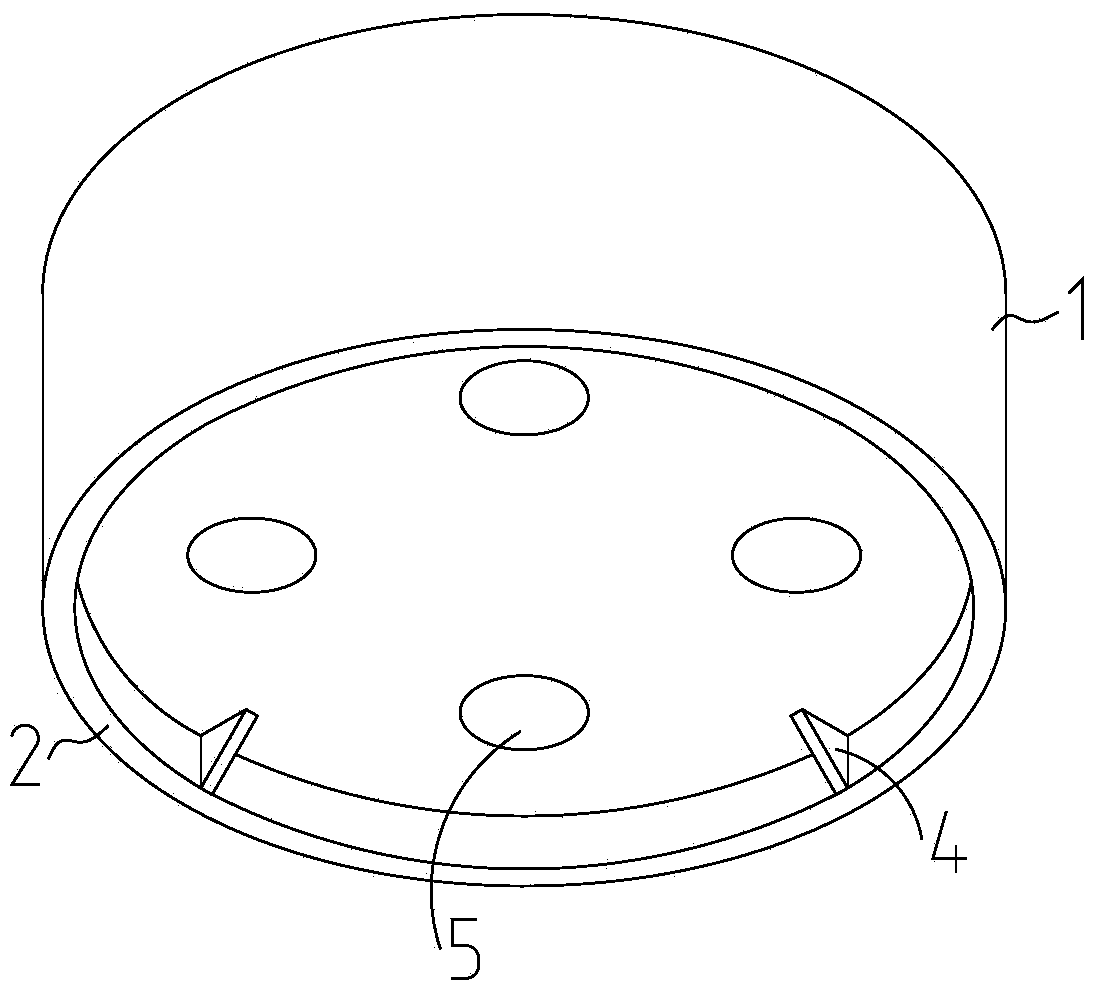

[0040] image 3 Shown is a schematic structural view of the rammer in the first embodiment of the present invention, and its front view, left view and top view can be referred to respectively Figure 4a , Figure 4b and Figure 4c . The rammer of the first embodiment includes a hammer body 1 and a ring device 2 is fixedly arranged on the hammer body 1 . The ring device 2 includes a vertical plate structure, and the bottom surface of the ring device 2 is lower than the bottom surface of the hammer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com