Anchor plate and anchor bolt assembly and anti-corrosion processing method of anchor bolt

A technology of assembly and anchor bolt, applied in the direction of bolts, connecting components, threaded fasteners, etc., can solve the problems of easy damage to the coating, loss of anti-corrosion ability, and inability to eliminate, achieve simple structure, prolong service life, prevent sucking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

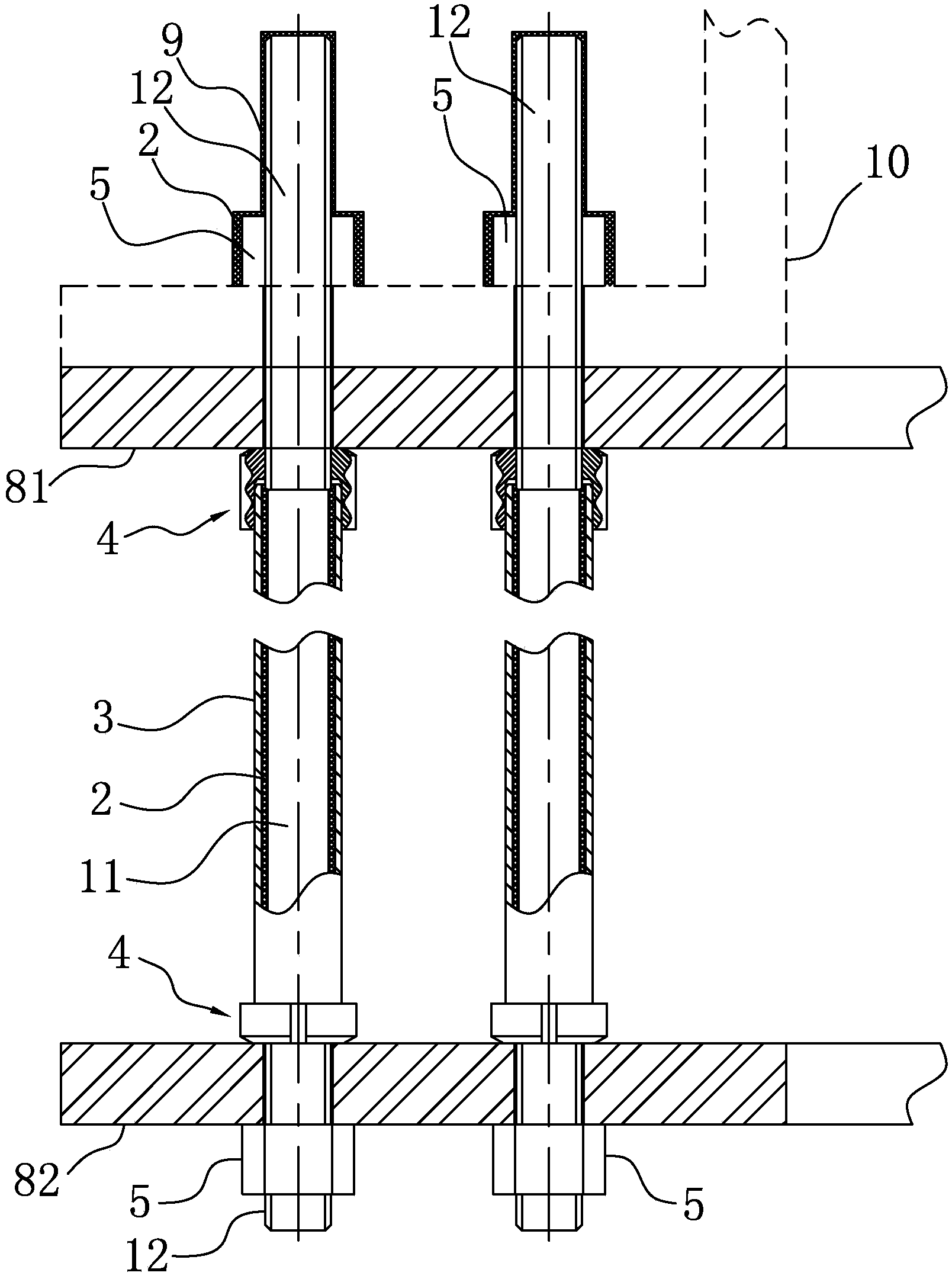

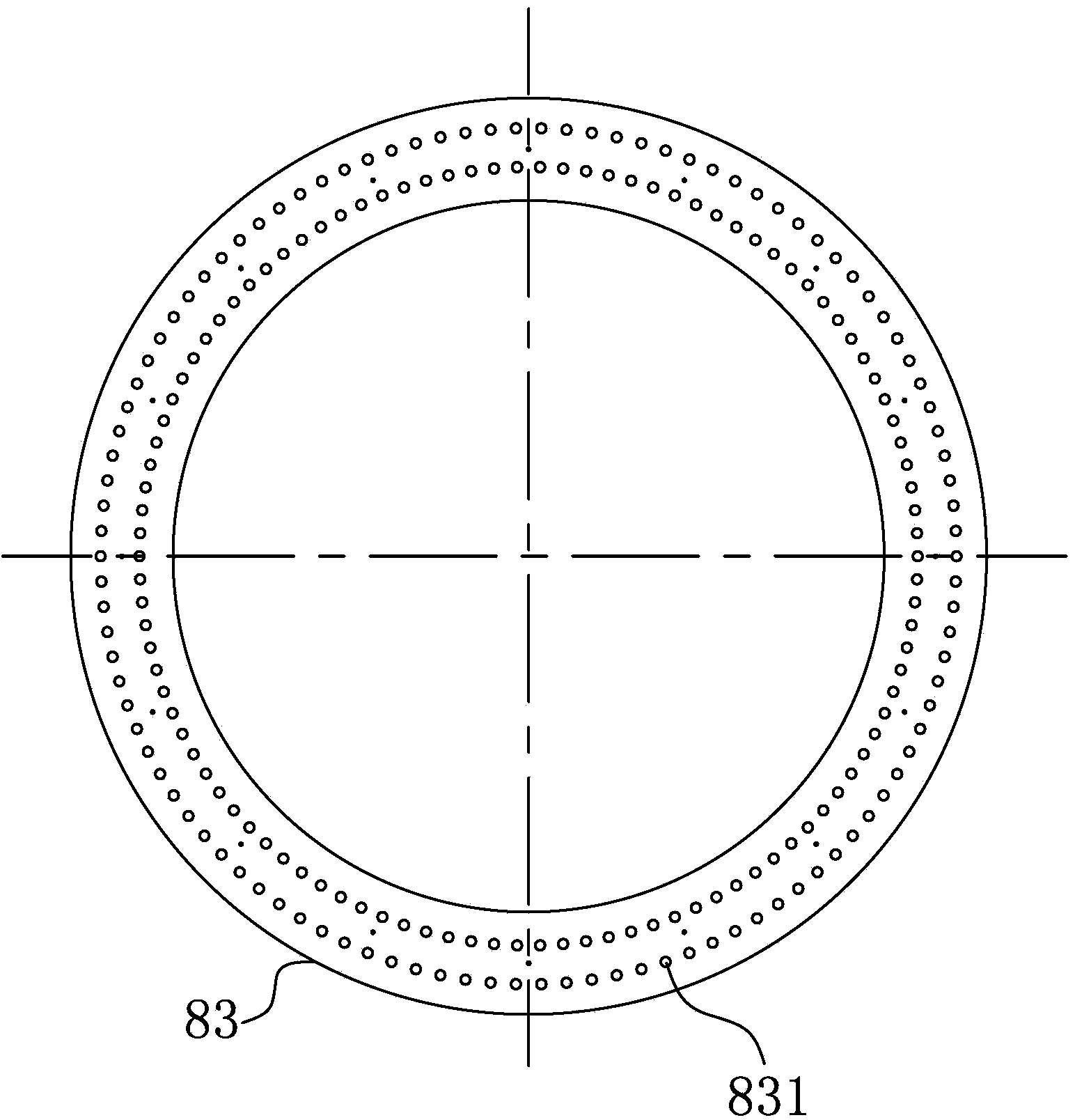

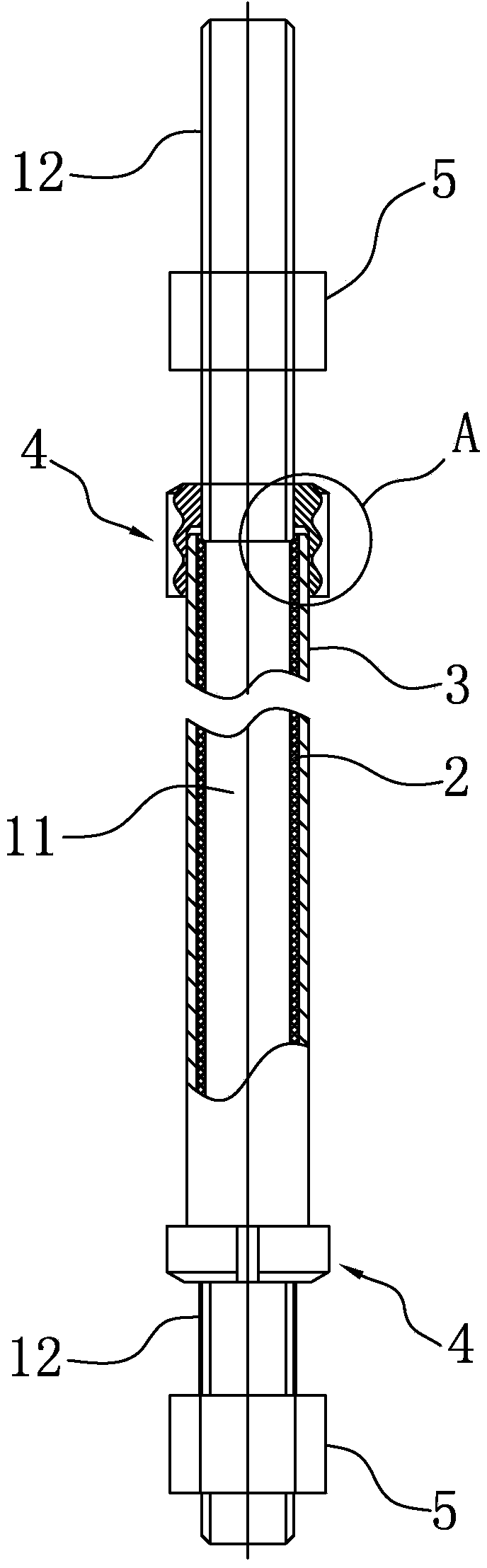

[0036] like figure 1 As shown, it is a partial cross-sectional view of the anchor plate and anchor bolt assembly of Embodiment 1 of the present invention. The anchor plate and anchor bolt assembly of this embodiment includes an upper anchor plate 81, a lower anchor plate 82 and a plurality of anchor bolts, such as image 3 As shown, the anchor bolt in this embodiment includes an anchor bolt body, and the anchor bolt body includes a middle section 11 and threaded sections 12 located on the upper and lower sides of the middle section 11. The middle section 11 is covered with a sheath 3, and the sheath 3 and the middle section 11 are provided with an anti-corrosion grease layer 2, and the threaded sections 12 on the upper and lower sides of the anchor bolt body are provided with a sealing nut 4 and a fastening nut 5, and the sealing nut 4 seals the anti-corrosion grease layer 2, see figure 1 , the upper anchor plate 81 is located between the plurality of fastening nuts 5 on the u...

Embodiment 2

[0049] The difference between this embodiment and the first embodiment lies in the sealing method between the sleeve part 42 and the sheath 3, such as Figure 5 As shown, it is a partial enlarged view of the anchor plate and anchor bolt assembly of the second embodiment, Figure 5 With Figure 4 The corresponding partial enlarged view shows the sealing structure between the sleeve part 42 and the sheath 3 in this embodiment.

[0050] In this embodiment, a first sealing ring 6 is provided between the end surface of the sheath 3 and the end surface of the threaded connection portion 41 . With such a sealing structure, the first sealing ring 6 can be conveniently and directly assembled between the end face of the sheath 3 and the threaded connection part 41 during assembly, and when the sealing nut is tightened, the first sealing ring 6 The end of the sheath 3 can be tightly sealed under the extrusion of the part 41, thereby enhancing the sealing effect on the sheath.

Embodiment 3

[0052] The difference between this embodiment and the above two embodiments lies in the sealing method between the sleeve part 42 and the sheath 3 . In this embodiment, at least one second sealing ring 7 is provided between the inner wall of the sleeve portion 42 and the outer wall of the sheath 3 . The second sealing ring 7 can be sleeved on the outer wall of the sheath 3 , and can be embedded on the inner wall of the sleeve part 42 . Compared with the sealing method of the second embodiment, the second sealing ring 7 can close the small gap between the inner wall of the sleeve part 42 and the outer wall of the end of the sheath 3 to enhance the sealing effect, and the inner wall of the sleeve part 42 A second sealing ring is provided between the outer wall of the sheath 3 to allow the sealing nut to move within a certain range on the threaded section 12 while maintaining a high sealing effect.

[0053] Preferably, as Image 6 As shown, an annular groove may be provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com