Buoyancy swing plate design adopting gravity sliding block

A slider and buoyancy technology, applied in mechanical equipment, ocean power generation, engine components, etc., can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

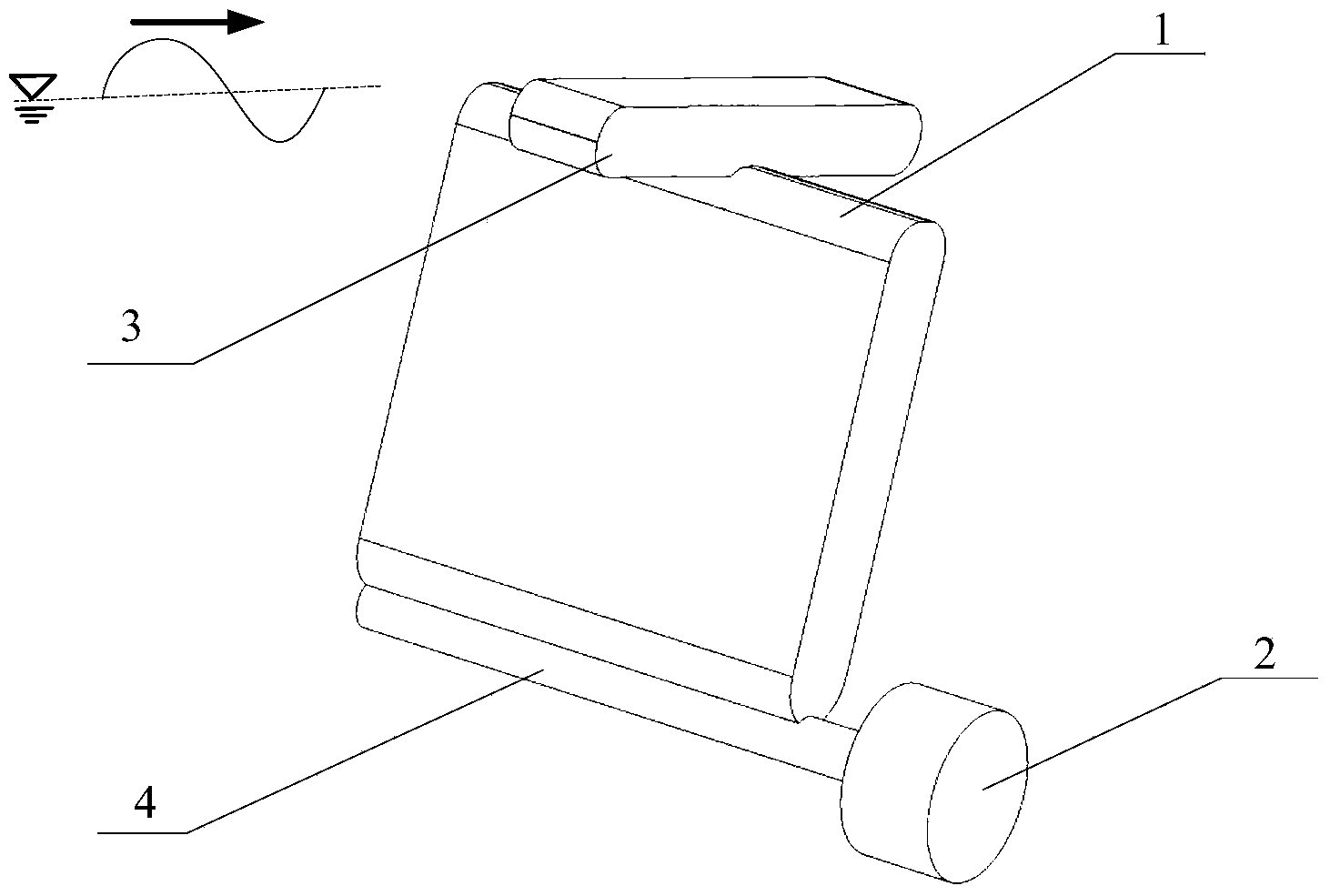

[0020] Such as figure 1 As shown, the pendulum plate 1 is fixed by the rotating shaft 4, and has a degree of freedom in one direction. The rotating shaft 4 is connected to the generator 2, and the pendulum plate 1 faces the incoming wave direction;

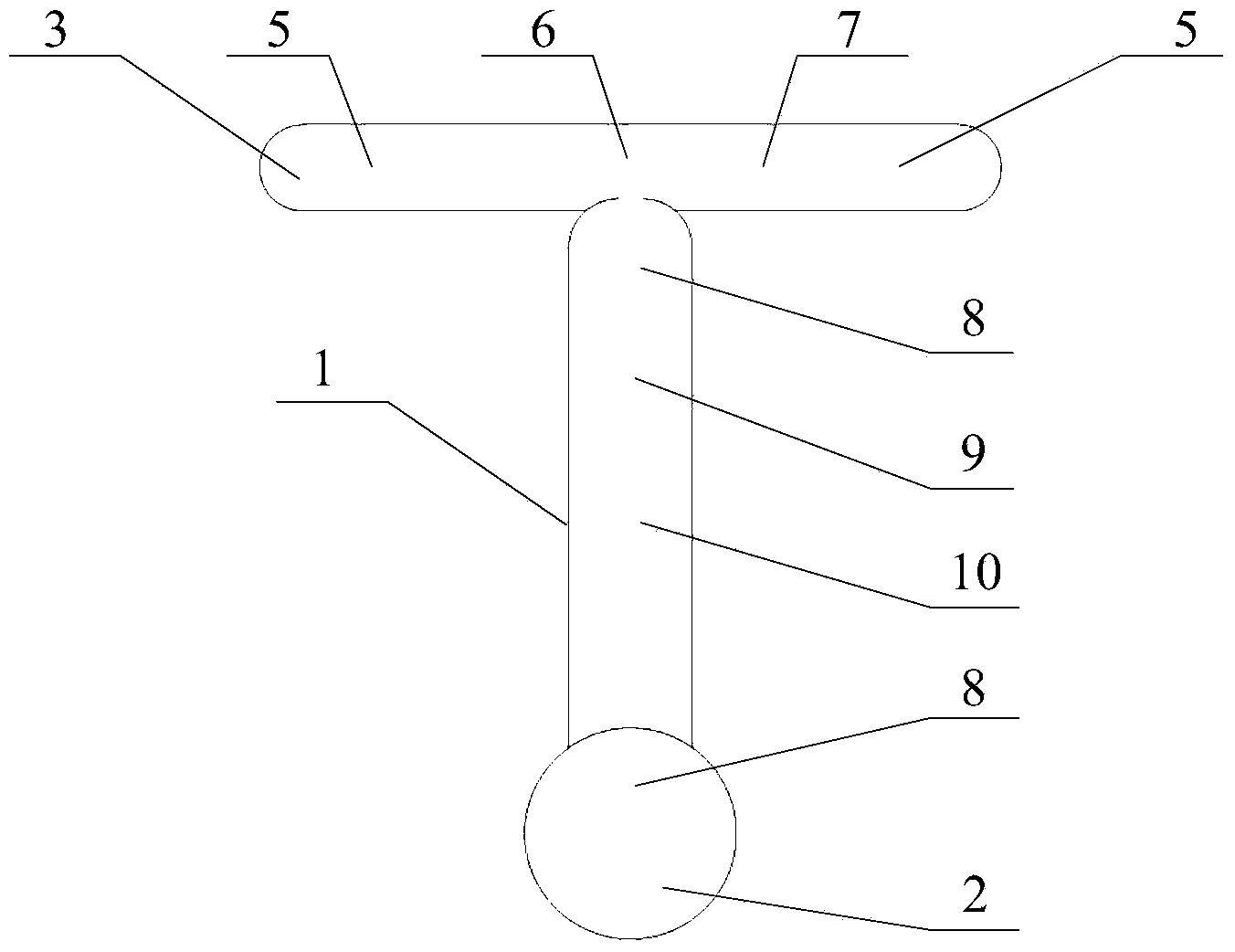

[0021] Such as figure 2 As shown, a gravity slider 10 and a sliding shaft 9 are installed inside the pendulum plate 1, and protective gaskets 8 are installed at both ends of the sliding shaft 9; similarly, a gravity slider 6 is also installed inside the slider cabin 3 And the sliding shaft 7, the two ends of the sliding shaft 7 are equipped with protective pads 5.

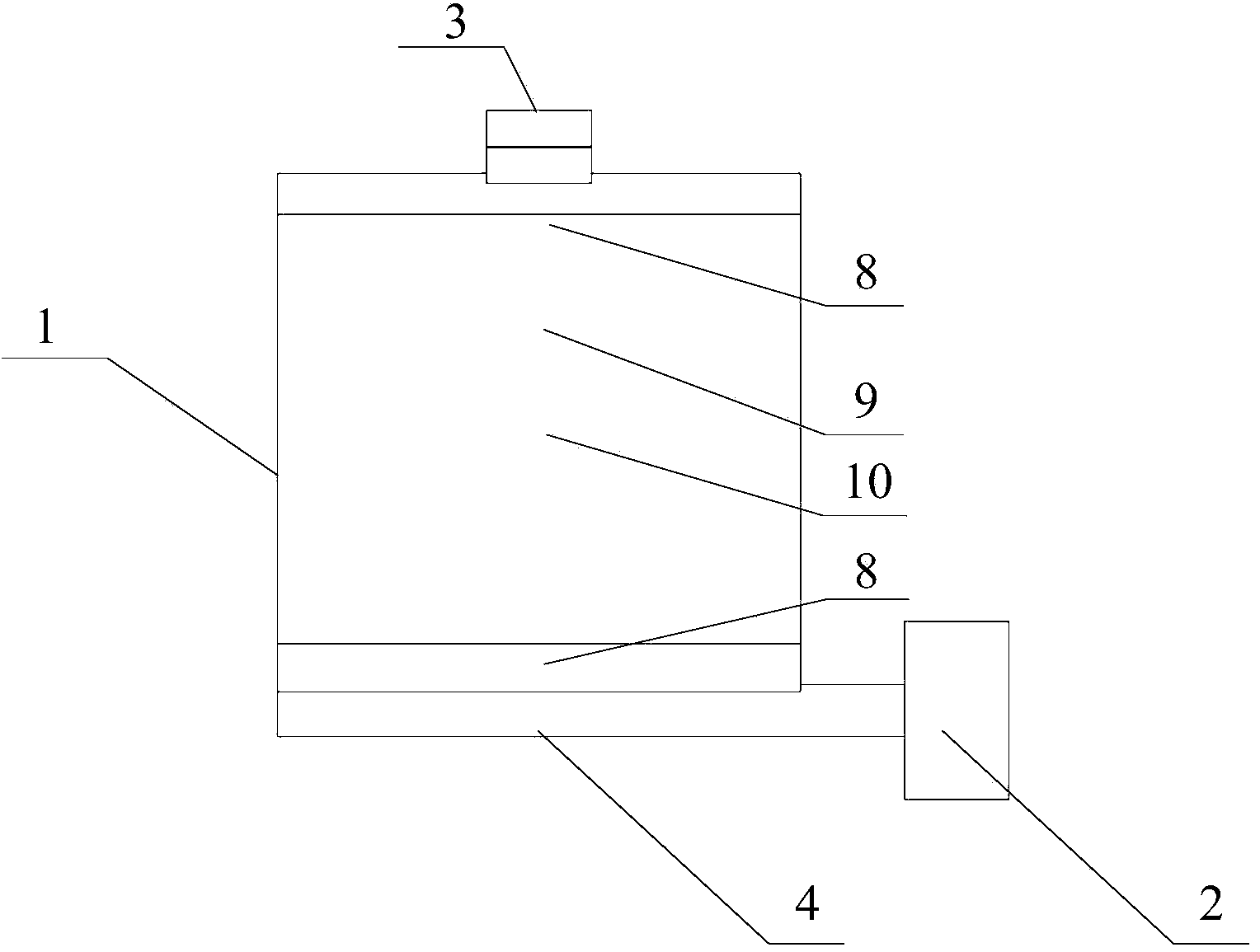

[0022] Such as image 3 As shown, the sliding shaft 9 inside the pendulum plate 1 is in the middle position, and the slider 10 can move along the sliding shaft 9 in a direction away from and close to the rotating shaft 4. The spacers 8 are arranged on the top and bottom of the sliding shaft 9 respectively. 9 two ends are connected with pendulum plate 1.

[0023] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com