A vertically integrated two-degree-of-freedom omni-directional rotating shaft and bearing assembly

An omnidirectional, rotating shaft technology, applied in the direction of pivot connection, etc., can solve the problems of high production and maintenance cost, low mechanical strength, unsuitable for sandstorm environment, etc. The effect of intrusion and long replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

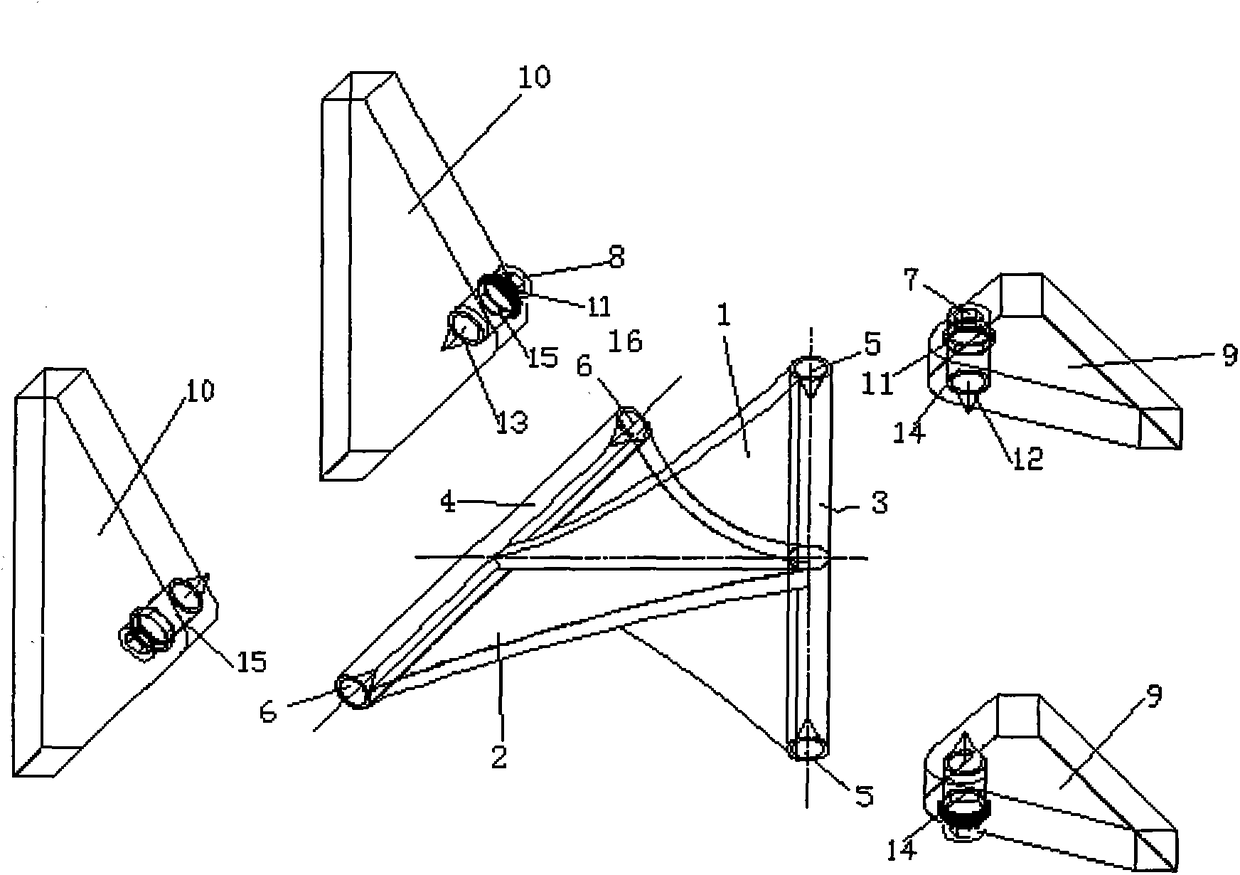

[0015] see figure 1 , in an embodiment of the present invention, a vertically integrated two-degree-of-freedom omnidirectional rotating shaft and bearing assembly is composed of a vertically integrated bearing part, a tapered shaft, a fastening screw part and a shaft support seat part, and the vertically integrated bearing part includes a vertical connection Body longitudinal surface 1, vertical connecting body horizontal surface 2, vertical integrated longitudinal bearing body 3, vertical integrated horizontal bearing body 4, vertical integrated longitudinal bearing 5 and vertical integrated horizontal bearing 6, the tapered shaft and fastening screw part include longitudinal axis pressure Tightening inner hexagon 7, horizontal axis pressing inner hexagon 8, fastening shaft and support seat nut 11, vertical taper shaft 12, horizontal taper shaft 13, longitudinal shaft body 14 and horizontal shaft body 15, the shaft support seat part includes longitudinal Shaft support seat 9 ...

Embodiment 2

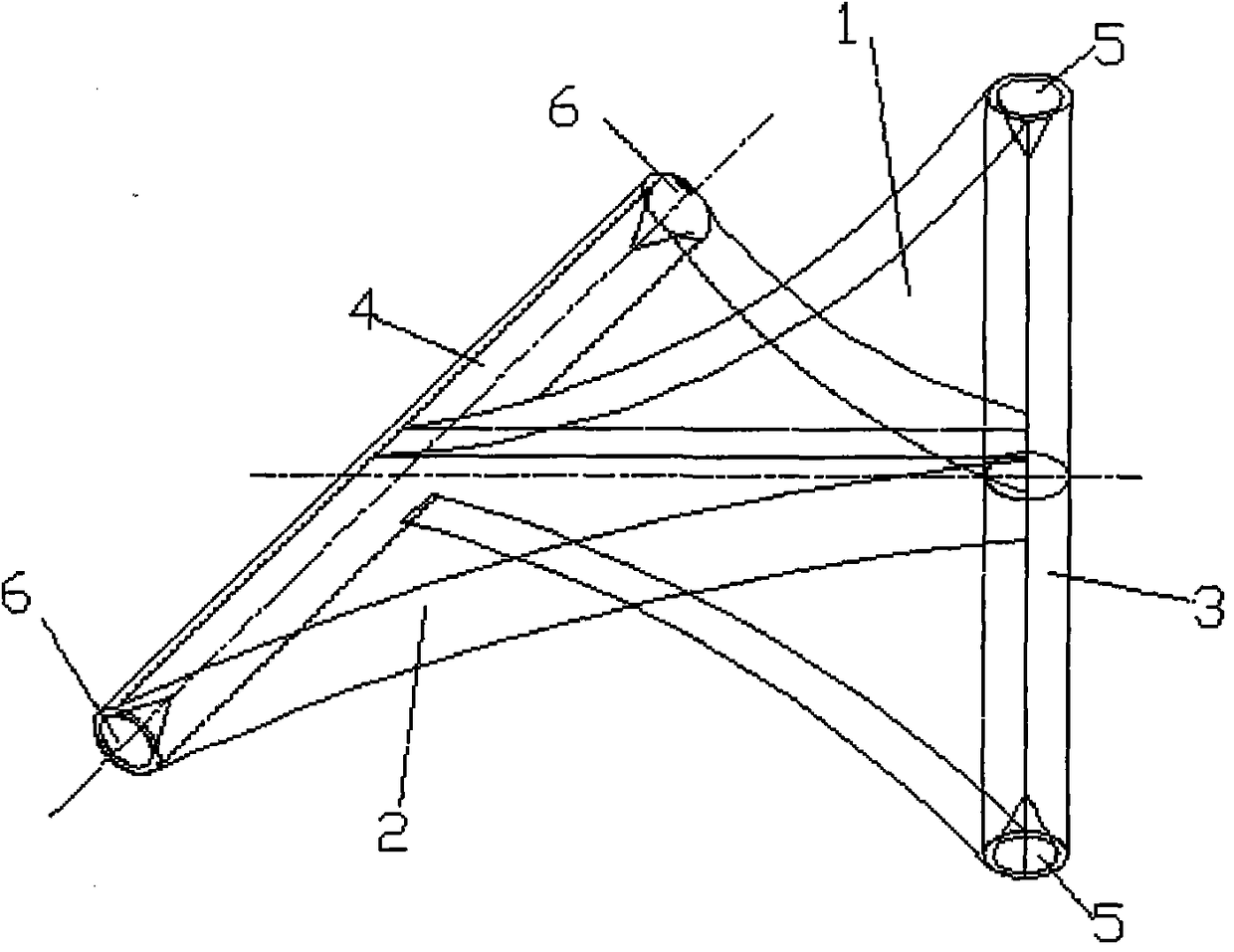

[0017] see figure 2 , in the two-degree-of-freedom rotary motion with high mechanical strength, this vertical integrated structure can be used. In this structure, the vertical connecting body longitudinal surface 1 and the vertical connecting body transverse surface 2 are a solid steel body.

Embodiment 3

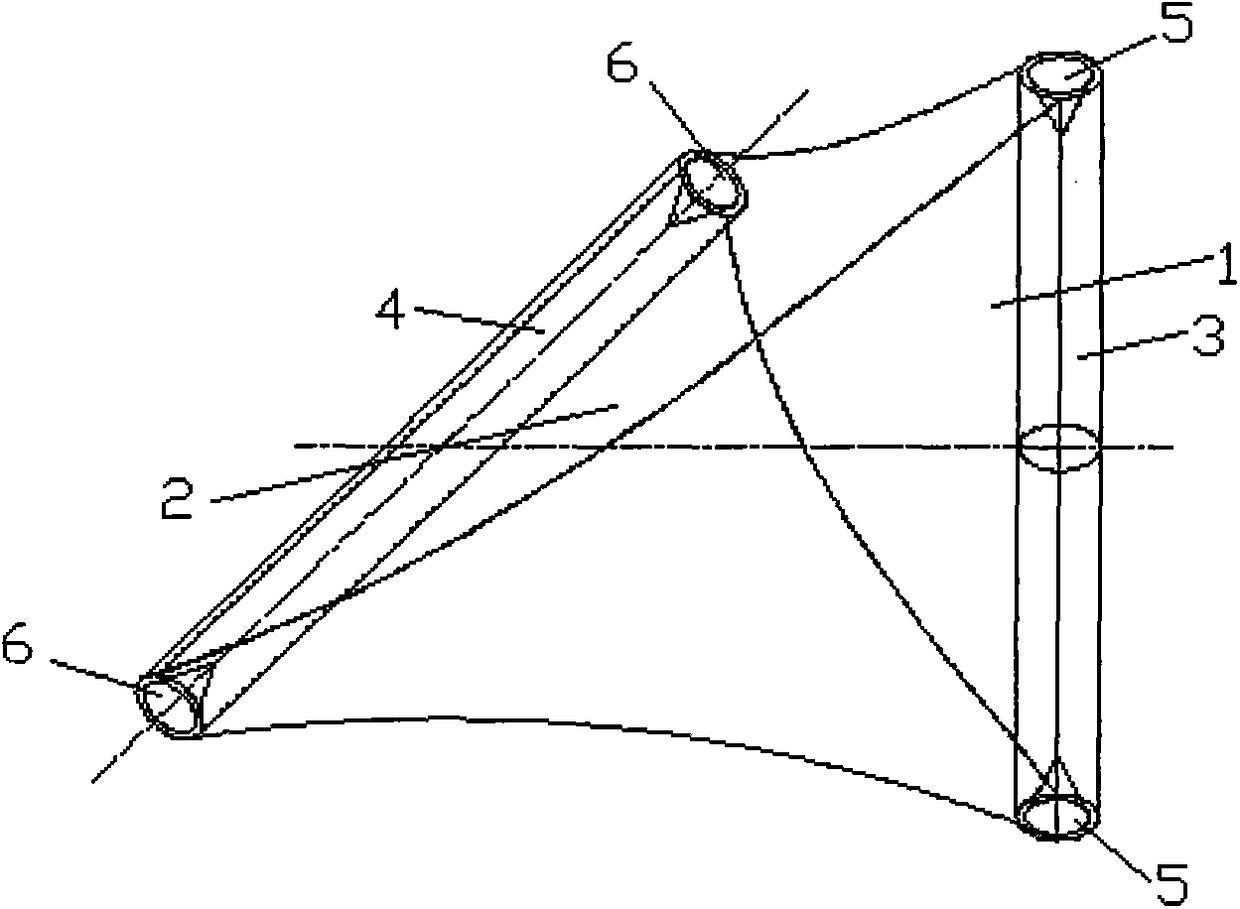

[0019] see image 3 , in the two-degree-of-freedom rotational motion with greater mechanical strength, this vertical integrated structure can be used. In this structure, the thickness of the vertical surface 1 of the vertical connector or the horizontal surface 2 of the vertical connector is the vertical integrated longitudinal bearing body 3 or the diameter of the vertical integral horizontal bearing body 4; the longitudinal surface 1 of the vertical connecting body and the horizontal surface 2 of the vertical connecting body are processed by steel.

[0020] The working principle of the present invention is: the vertical integrated bearing part is a vertical bearing with different planes in space, and the centerlines of the two bearings are perpendicular to different planes in space; the two ends corresponding to each pair of bearings are tapered shafts, which are respectively fixed on their respective support seats; One end of the shaft is a tapered shaft surface, which has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com