Storage-tank-type crescent corrugated pipe assembly

A corrugated tube and crescent-shaped technology, which is applied in the field of aerospace engine fuel storage tank products, can solve the problems of not meeting the requirements of storage tank products, small axial compensation displacement of formed bellows, high leakage rate of welded bellows, etc., and achieve a large Application value, reducing leakage hazards, and increasing the effect of fatigue life times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

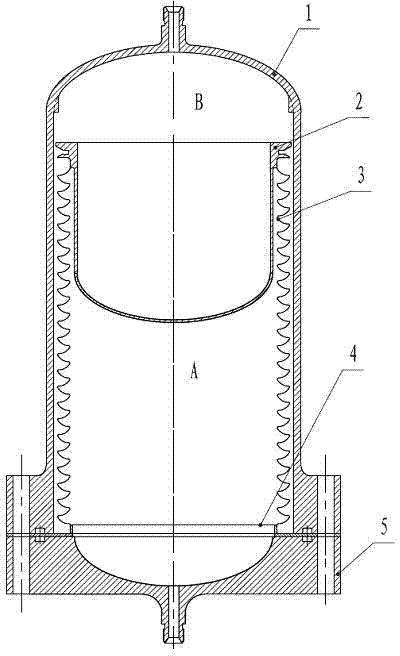

[0012] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

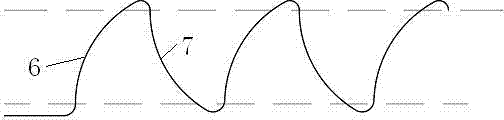

[0013] A tank-type "crescent" bellows assembly, including a "crescent" bellows 3, a butt ring 4, a sleeve 2, a head 5 and a housing 1, wherein the "crescent" bellows 3 There is one longitudinal weld, and each corrugation includes a concave side 6 and a convex side 7, the concave side 6 and the convex side 7 fit together in a compressed state, one end of the "crescent" bellows 3 is electron beam welded to the docking ring 4, and the other One end is electron beam welded with the sleeve 2, and the shell is set outside the "crescent" bellows 3, the docking ring 4 and the sleeve 2, and the docking ring 4 is connected with the head 5 and the shell 1 by bolts, The "crescent" bellows 3 and the docking ring 4, the sleeve 2 and the head 5 form the bellows inner cavity A, and the "crescent" bellows 3 and the docking ring 4, the sleeve 2 and the shell 1 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com