Hexagonal prism reversed heat transmission machine core and heat recovery new wind machine thereof

A hexagonal and core technology, which is applied in the field of air energy recovery, high efficiency and energy saving in ventilation equipment, can solve the problems of not being able to meet the high heat transfer effect of the anisotropic film, failing to effectively utilize the anisotropic film, and the aging of the fresh air fan structure. Achieve stable and convenient assembly, improve energy saving effect, and facilitate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

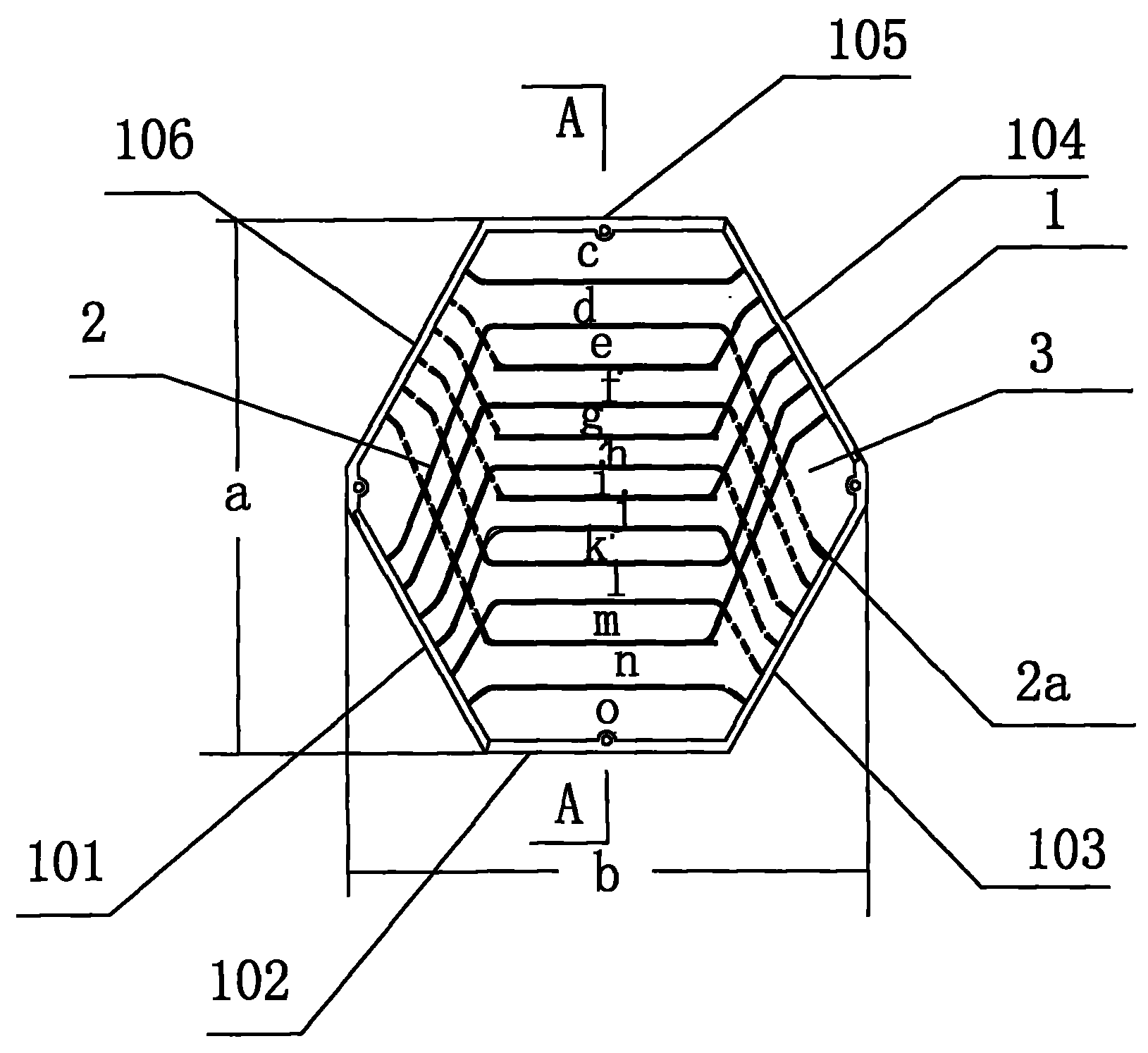

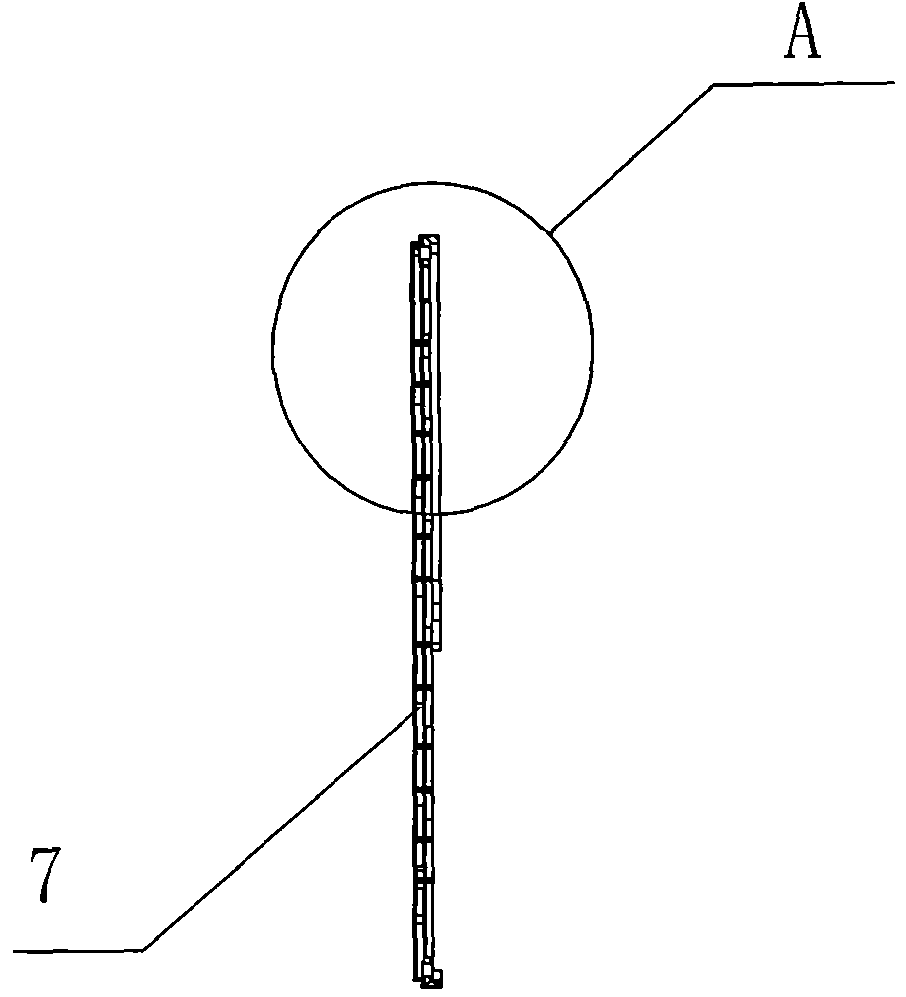

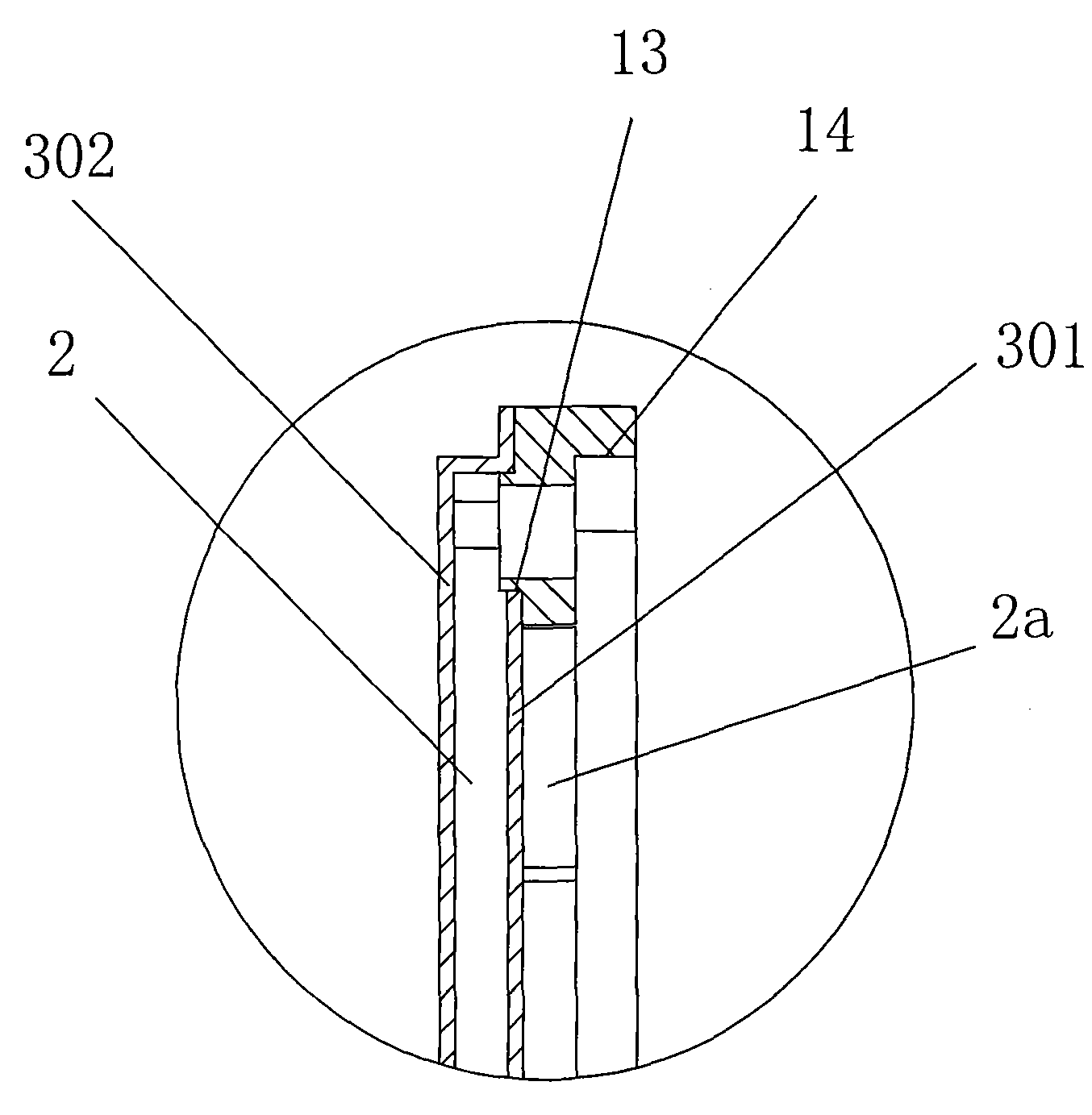

[0052] Such as Figure 1-1 to Figure 5 As shown, the hexagonal reverse heat transfer core includes a frame 1, a bracket, a hexagonal heat transfer film layer 3, an upper cover 4, a lower cover 5 and a fixing rod 6; the frame 1 is hexagonal, and the frame 1 Including A side 101, B side 102, C side 103, D side 104, E side 105, F side 106; B side 102 and E side 105 are set up and down, and the distance a between B side 102 and E side 105 is hexagonal The height a of square frame, height a is 340mm; The distance b between the intersection point of left side A side 101, F side 106 and the intersection point of right side C side 103, D side 104 is the width b of hexagonal frame, width b is 340mm; the bracket includes an upper bracket 2 and a lower bracket 2a, the hexagonal heat transfer film layer 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com