A Heating Furnace for Plate Sample Fatigue Test

A technology for plate sample and fatigue testing, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of inconvenient operation, unsatisfactory test temperature, low intelligence, etc. Easy to upgrade, overall compact and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

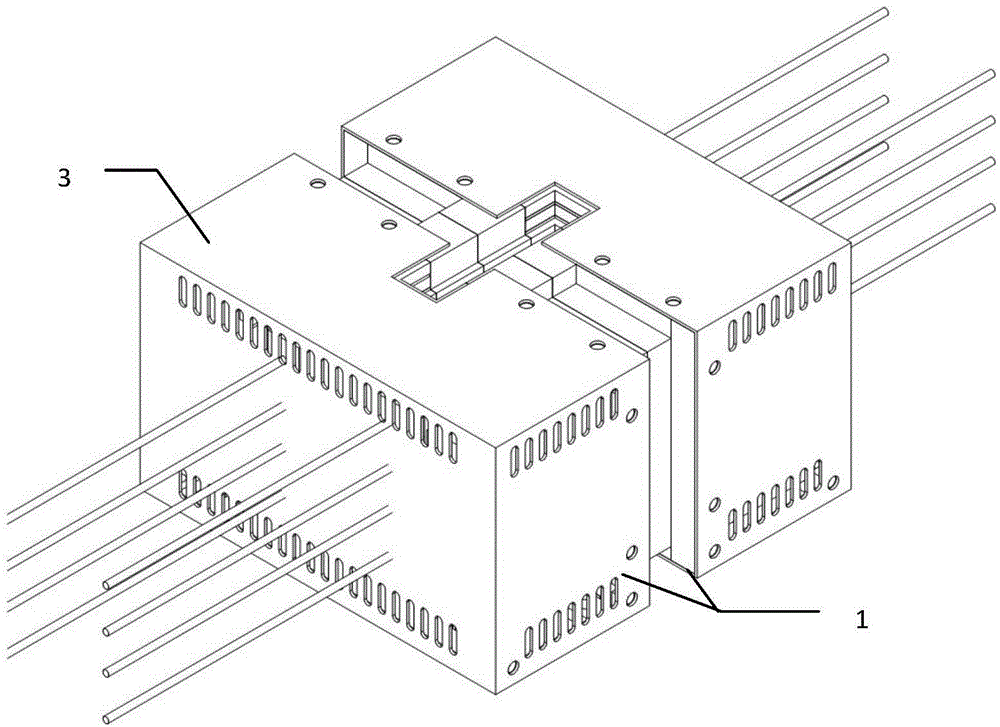

[0018] 1. Design a heating furnace for high temperature fatigue test of thin-walled plate samples. The overall dimensions are: height 50mmX width 60mmX depth 60mm, the shell of the heating furnace is a cuboid, the size is: height 90mmX width 150mmX depth 150mm, the size of the installation groove for installing the plate sample is: width 60mmX depth 10mm.

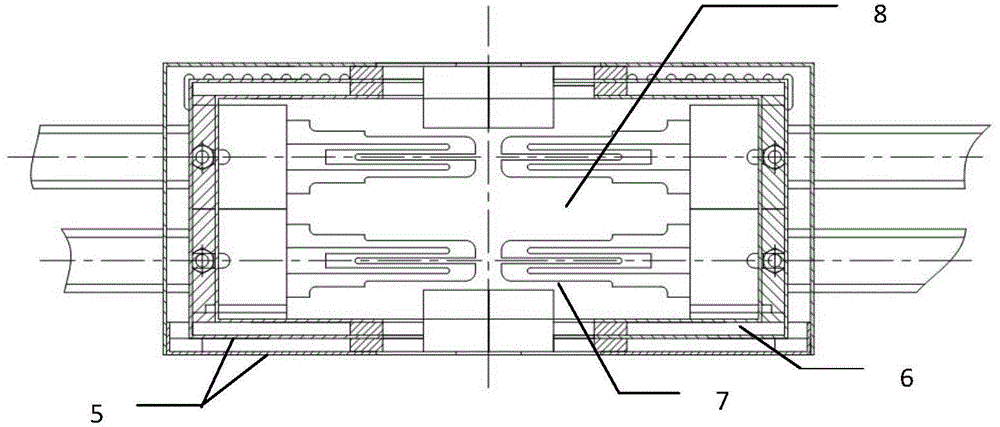

[0019] 2. The strip-shaped silicon carbide heating element is adopted, the size is: width 12.5mmX length 50mm, two groups are placed up and down, each group of heating elements can provide a maximum power of more than 600W, and the sample is heated to the working temperature within 30 minutes 1200°C. By connecting the temperature control system, the two sets of heating elements form the upper and lower two-stage heating system in the heating chamber of the heating furnace, so as to realize the automatic adjustment of the temperature gradient during the heating process and form the optimal temperature deviation at the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com