A kind of multifunctional coil induction heating equipment and heating method thereof

A technology of induction heating equipment and heating method, which is applied in the direction of induction heating, lighting and heating equipment, coil devices, etc., can solve the problems of low efficiency, low heat conversion efficiency, labor and material resources, and achieve fast heating and automation High degree, good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

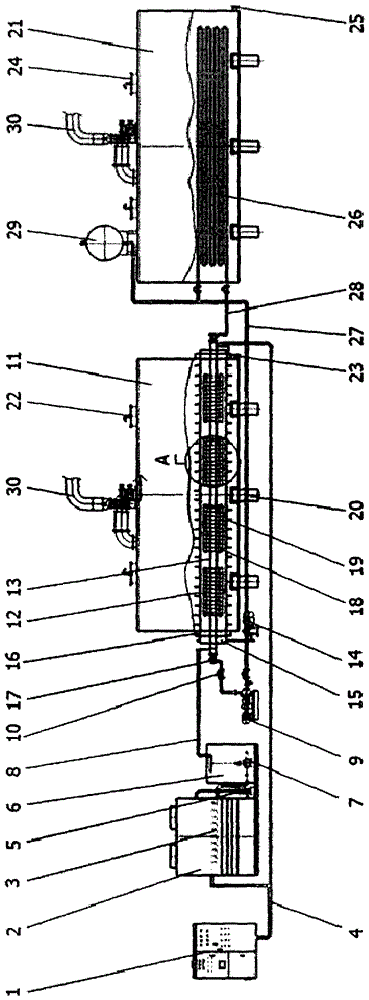

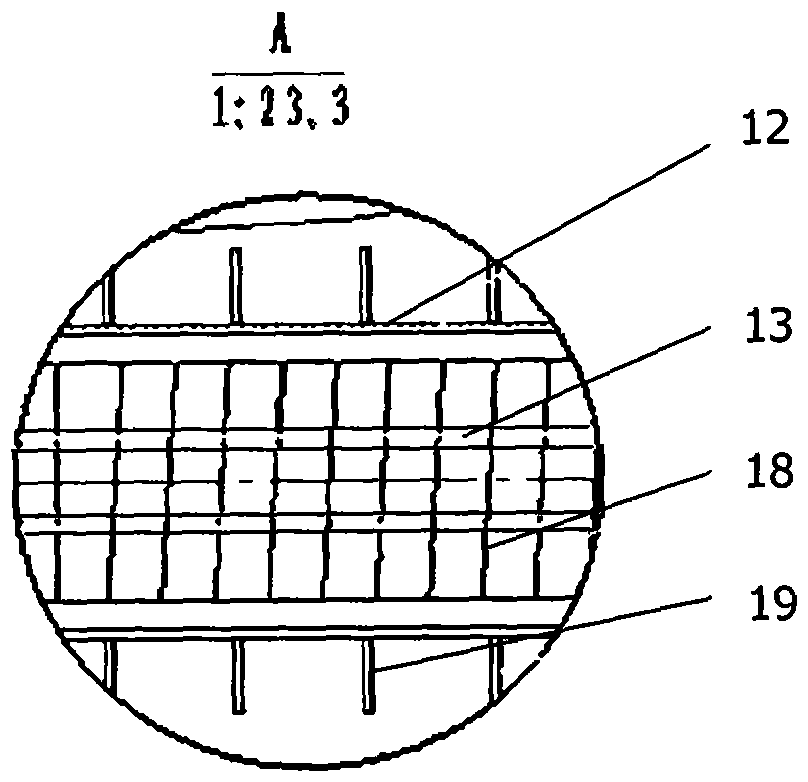

[0027] Embodiment 1: A kind of multifunctional coil induction heating equipment, including control cabinet 1, cooling system 2, main heating body 11, auxiliary heating body 121, heat conduction oil circulation pump 9, control cabinet 1 and cooling system 2 and main heating body 11 connected, the cooling system 2 is a water cooling system with a cooler 3 inside, a cooling pipeline pump 5 and a circulating water pipeline pump 7 outside, and the circulating water pipeline pump 7 sends the cooling water in the water tank 6 to the distribution The hollow coil in the electric cabinet 1 and the induction coil heating device 18 is circulated and cooled, so that the induction coil heating device can work in a certain temperature range to ensure the efficiency of induction heating; the main heating body 11 is in the form of a tank body, U-shaped or W type, or other forms, the main heating body 11 can be made single layer, also can be double-layer or multi-layer; The main heating body 11 ...

Embodiment 2

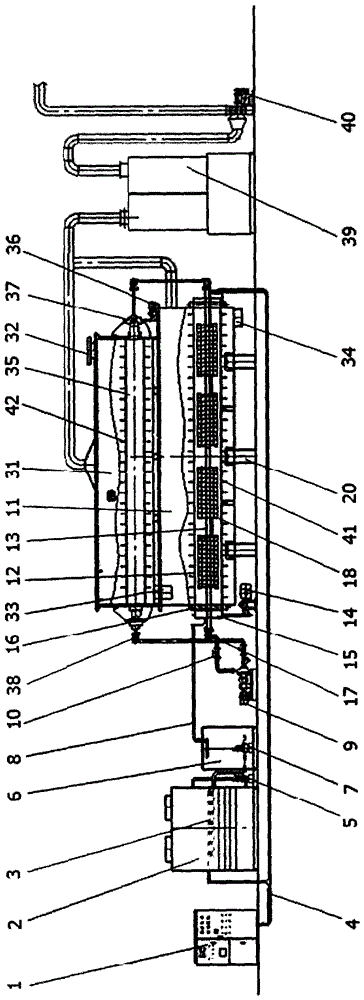

[0029] Embodiment 2: A multifunctional coil induction heating device, including a control cabinet 1, a cooling system 2, a main heating body 11, a secondary heating body II 31, a heat transfer oil circulation pump 9; a control cabinet 1, a cooling system 2 and a main heating body 11 connected, the cooling system 2 is a water cooling system with a cooler 3 inside, a cooling pipeline pump 5 and a circulating water pipeline pump 7 outside, and the circulating water pipeline pump 7 sends the cooling water in the water tank 6 to the distribution The electric cabinet 1 and the hollow coil in the induction coil heating device 18 carry out circulating cooling, so that the induction coil heating device can work in a certain temperature range and ensure the efficiency of induction heating; the main heating body 11 is in the form of a tank body or a box body , U-shaped or W-shaped, or other forms, the main heating body 11 can be made into a single layer, or double or multi-layered; the ma...

Embodiment 3

[0031] Embodiment 3: A multifunctional coil induction heating device, including a control cabinet 1, a cooling system 2, a main heating body 11, a secondary heating body II 31, a heat transfer oil circulation pump 9; a control cabinet 1, a cooling system 2 and a main heating body 11 connected, the cooling system 2 is a water cooling system with a cooler 3 inside, a cooling pipeline pump 5 and a circulating water pipeline pump 7 outside, and the circulating water pipeline pump 7 sends the cooling water in the water tank 6 to the distribution The electric cabinet 1 and the hollow coil in the induction coil heating device 18 carry out circulating cooling, so that the induction coil heating device can work in a certain temperature range and ensure the efficiency of induction heating; the main heating body 11 is in the form of a tank body or a box body , U-shaped or W-shaped, or other forms, the main heating body 11 can be made into a single layer, or double or multi-layered; the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com