A vacuum electron microscope sample vacuum pre-reaction chamber

An electron microscope sample and pre-reaction technology, which is applied in the preparation of test samples and other directions, can solve the problem that the ambient gas cannot be corrosive, and achieve the effect of broadening the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

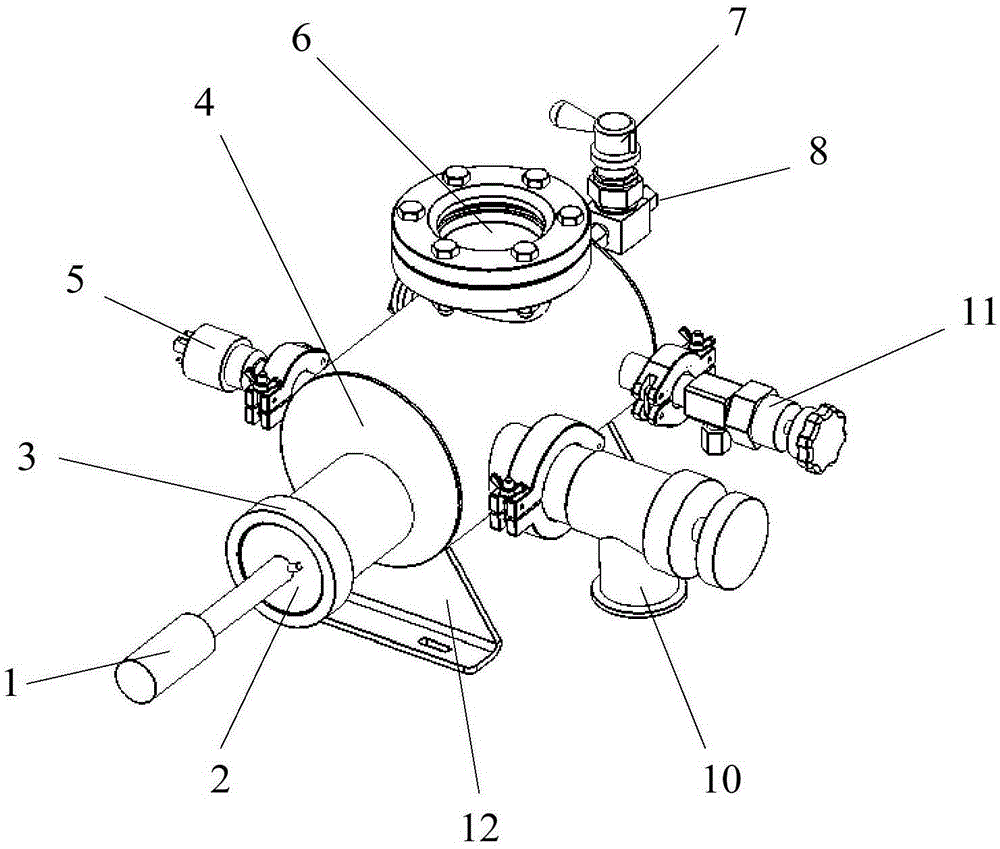

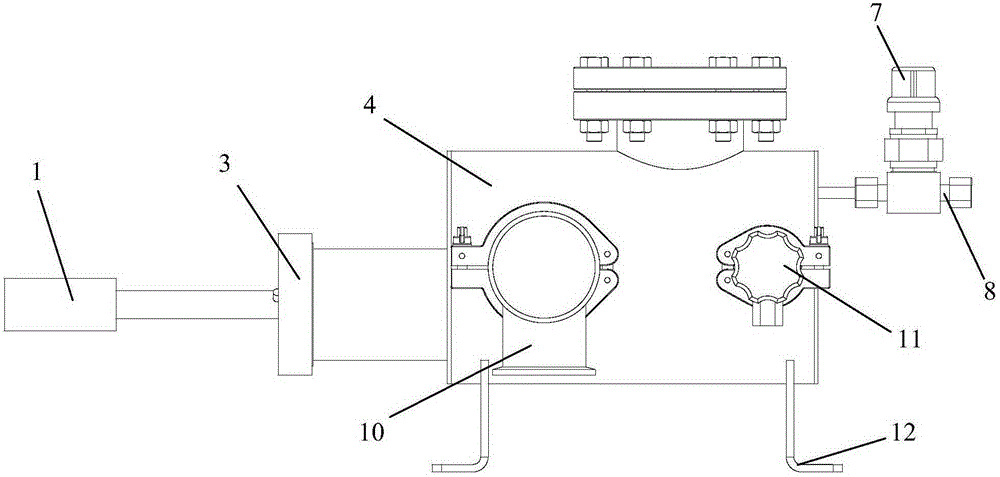

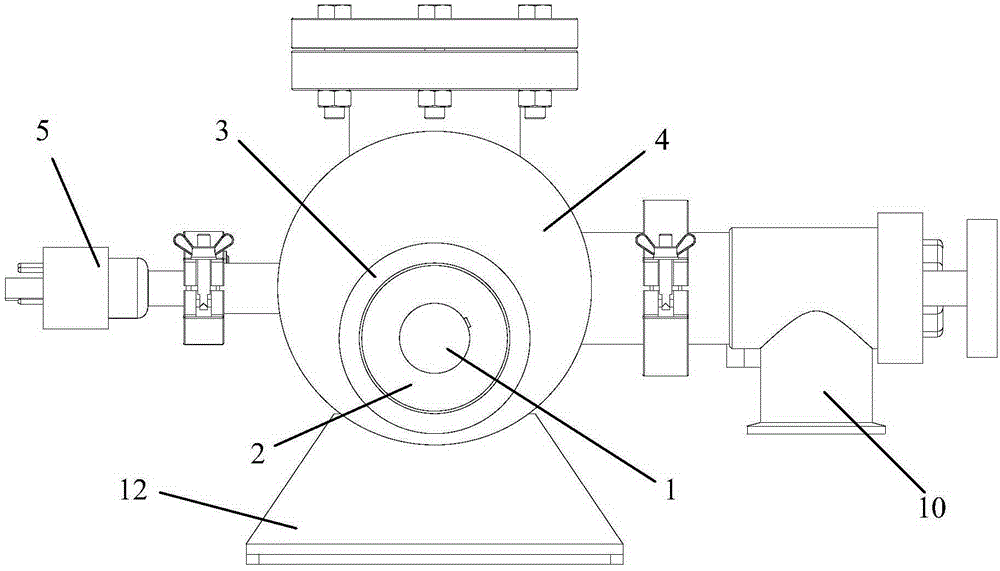

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0027] see figure 1 , the present invention includes two stainless steel brackets 12 with a spacing of 150mm, and a vacuum chamber 4 installed on the brackets 12, the vacuum chamber 4 is a columnar 316L stainless steel chamber, and its front end is provided with a transition for reducing the volume Tube 13; the front end of the vacuum chamber 4 is connected with an adapter sleeve, and the adapter sleeve is connected with a sample rod 1, the sample rod 1 is a 316L stainless steel sample rod with a smooth surface and a sealing ring; the connection sleeve includes a The cavity is matched with an adapter flange 2 with a sealing ring, and the adapter flange 2 is fixed and sealed on the vacuum cavity 4 by nuts 3 . One side of the vacuum chamber 4 is provided side by side with an exhaust valve set 10 connected to the external vacuum pump and an exhaust valve set 11 for rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com