Ring part structure and machining method thereof

A processing method and ring technology, which is applied in the ring structure and its processing field, can solve the problems of spalling and tip discharge particles, and achieve the possible effects of reducing the tip, improving the service life, and reducing the phenomenon of peeling of attached particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

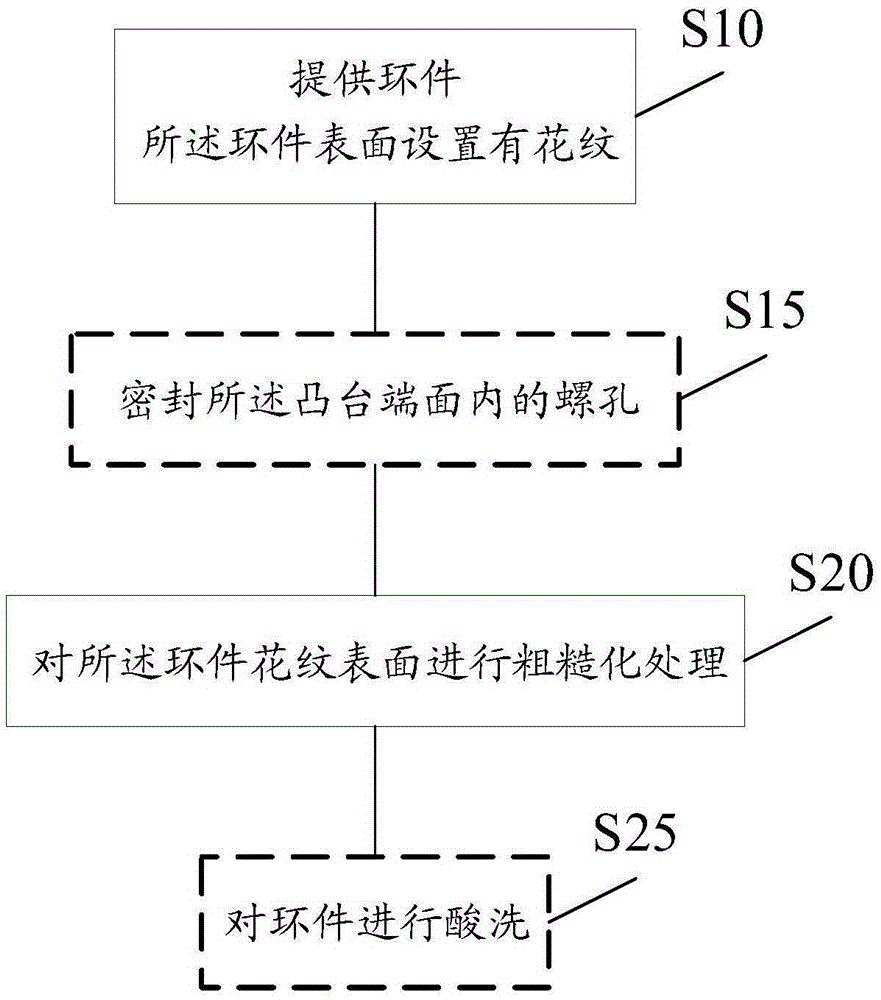

[0035] It can be seen from the background art that the rings in the prior art have the problem that the surface of the pattern is prone to tip discharge or peeling off of the adsorbed particles. Now combine the structure of the ring to analyze the causes of the tip discharge and the peeling off of the adsorbed particles:

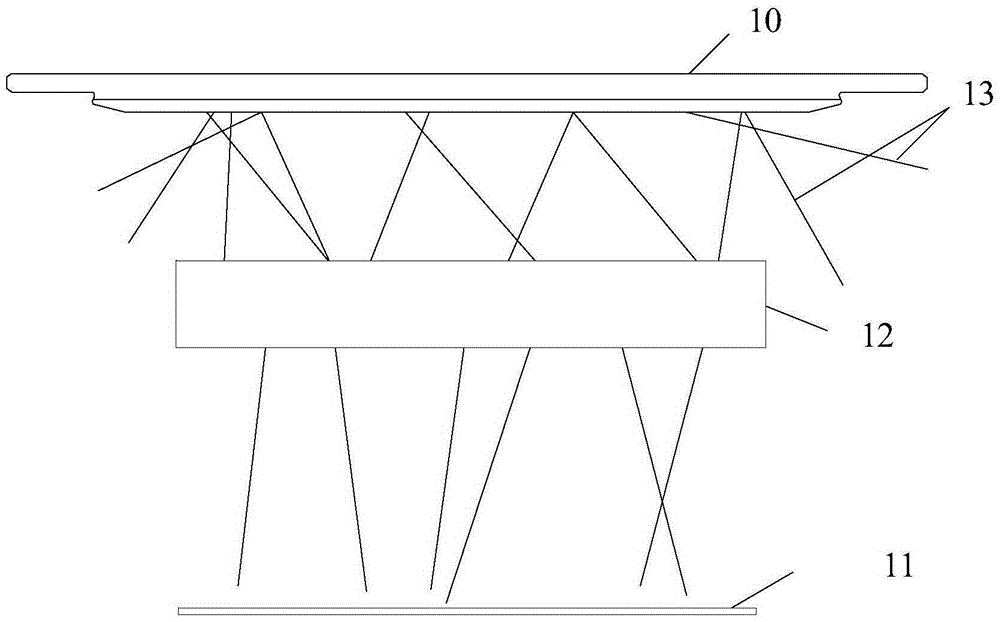

[0036] As mentioned in the background technology, the ring has two main functions in the sputtering process: one is to restrict the trajectory of the sputtered ions and play a role of focusing; the other is to absorb the particles produced in the sputtering process to purify role.

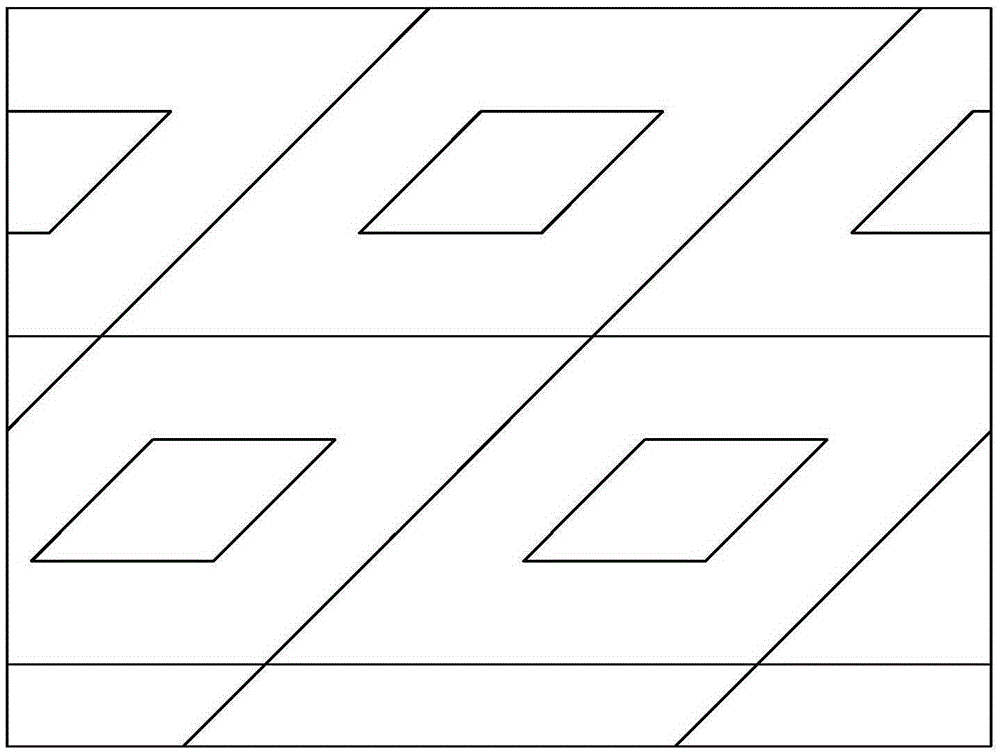

[0037] refer to figure 2 ,show figure 1 Schematic diagram of the pattern on the surface of the middle ring.

[0038] In order to improve the adsorption capacity of the ring to particles, the surface of the ring is provided with patterns to increase the roughness of the surface of the ring and improve the adsorption capacity of the surface of the ring. However, if the pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com