Sintering treatment method for gagate dry method waste desulfurizer

A waste desulfurizer and dry desulfurization technology, which is applied in chemical instruments and methods, sulfur compounds, and process efficiency improvement, etc., can solve problems such as difficult treatment, hidden safety hazards of hazardous wastes, etc., and achieve the effect of high recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

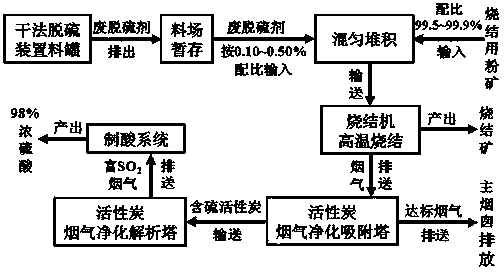

Method used

Image

Examples

Embodiment 1

[0035] Example 1 The following steps are used to treat the waste desulfurizer produced by Baosteel Zhanjiang Iron and Steel Coking Coal Refined Dry Desulfurization Unit in the production of No. 1 and No. 2 sintering machines of Zhanjiang Iron and Steel:

[0036] (1) Treatment before taking out the waste desulfurization agent: before taking the waste desulfurization agent out of the tank of the dry desulfurization device, fill the dry desulfurization device with nitrogen for purging, replace the gas in the tower, and then take out the waste desulfurization agent;

[0037] (2) Pre-mixing and dilution stacking: transport the taken out waste desulfurizer to the stockyard, where the waste desulfurizer is pre-mixed with 2~3 times the mass of iron ore powder (Yangdi ore powder) and stacked after dilution Store in the stockyard to obtain the diluted waste desulfurizer mixed material; control the stockpile temperature below 50°C;

[0038] (3) Mixing and stacking of powder ore for sinte...

Embodiment 2

[0044] Embodiment 2 Adopt the following steps to realize the present invention:

[0045] (1) Treatment before taking out the waste desulfurization agent: before taking the waste desulfurization agent out of the tank of the dry desulfurization device, fill the dry desulfurization device with nitrogen for purging, replace the gas in the tower, and then take out the waste desulfurization agent;

[0046](2) Pre-mixing, dilution and stacking: transport the taken out waste desulfurizer to the stockyard, where the waste desulfurizer and iron ore powder (Yangdi ore powder) of twice the mass are pre-mixed, diluted, and stored in In the stockyard, the diluted waste desulfurizer mixed material is obtained; the temperature of the stockpile is controlled below 45°C;

[0047] (3) Mixing and stacking of powder ore for sintering: the diluted waste desulfurizer mixture in the stockyard is sent to the mixing silo through the reclaimer, and the cut-out amount is cut out from the mixing silo acco...

Embodiment 3

[0052] Embodiment 3 Adopt the following steps to realize the present invention:

[0053] (1) Treatment before taking out the waste desulfurization agent: before taking the waste desulfurization agent out of the tank of the dry desulfurization device, fill the dry desulfurization device with nitrogen for purging, replace the gas in the tower, and then take out the waste desulfurization agent;

[0054] (2) Pre-mixing, dilution and stacking: transport the taken out waste desulfurizer to the stockyard, where the waste desulfurizer and 3 times the mass of iron ore powder (Yangdi ore powder) are pre-mixed, diluted and stored in In the stockyard, the diluted waste desulfurization agent mixed material is obtained; the temperature of the stockpile is controlled below 50°C;

[0055] (3) Mixing and stacking of powder ore for sintering: the diluted waste desulfurizer mixture in the stockyard is sent to the mixing silo through the reclaimer, and the cut-out amount is cut out from the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com