A variable load rolling friction and wear testing machine

A wear test and rolling friction technology, applied in the direction of testing wear resistance, using mechanical devices, measuring devices, etc., can solve the problems of small loading range, insufficient simulation, lack of lubricating temperature control system, etc., to achieve accurate measurement, structural Simple, full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

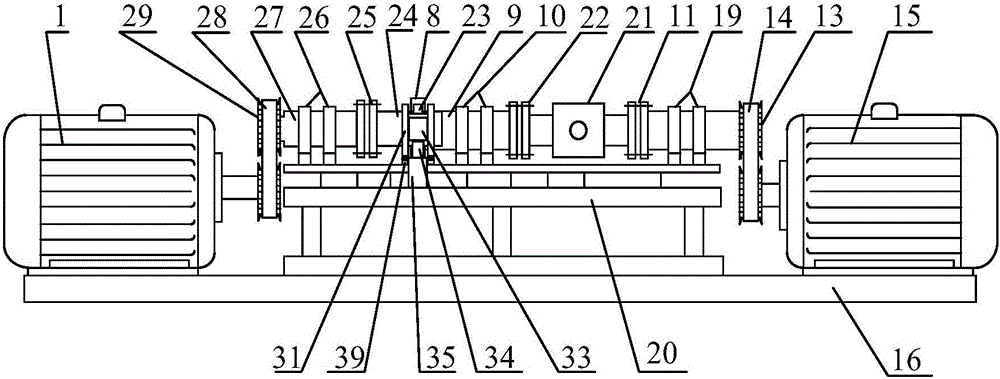

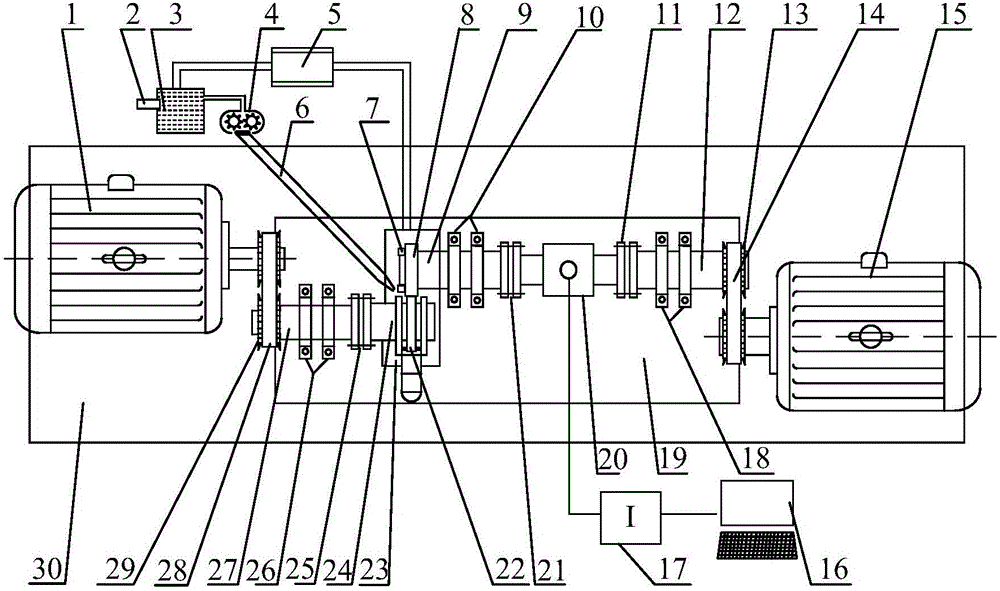

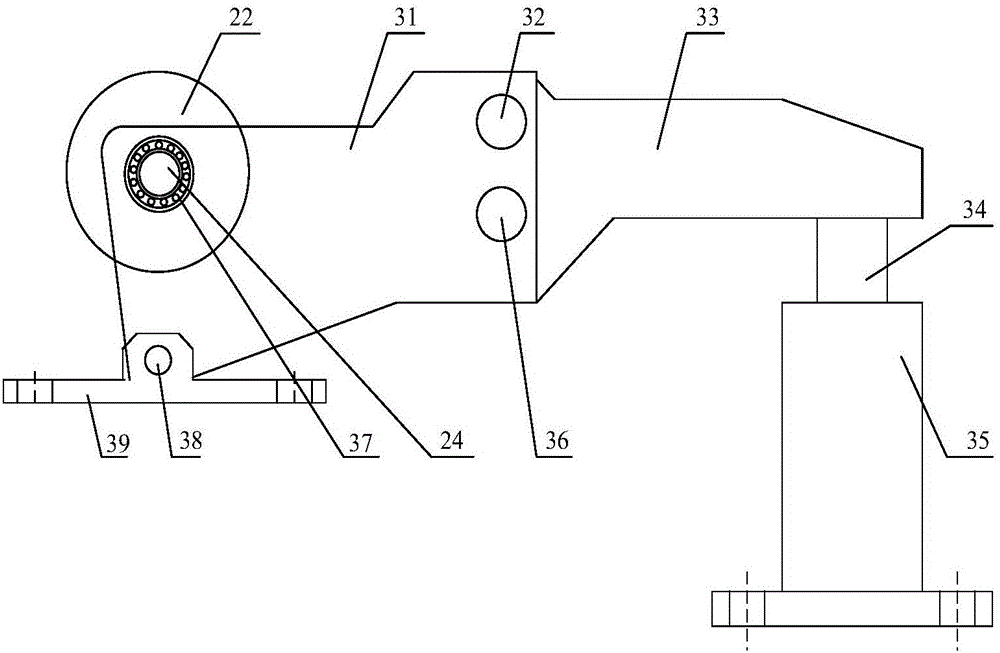

[0013] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. Such as figure 1 and figure 2 As shown, the testing machine adopts the driving method of dual motors driving the transmission components at the same time, forming two power transmission lines: the right motor 15 passes through the right pulley pair 13, the right pulley shaft 12, the right coupling 11, the torque sensor 20, the middle The coupling 21 is connected with the fixed load shaft 9, and the active friction ring sample 8 is fixed on the end of the fixed load shaft 9 through threads and lock nuts 7; the left motor 1 passes through the left pulley pair 29, the left pulley shaft 27, and the left coupling The device 25 is connected to the mobile load shaft 24, and the passive friction ring sample 22 is fixed on the mobile load shaft 24 by threads. The right motor 15 and the left motor 1 are fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com