Load separation performance test device of separation and stripping electric connector

An electrical connector and separation performance technology, applied in the field of parameter measurement, to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

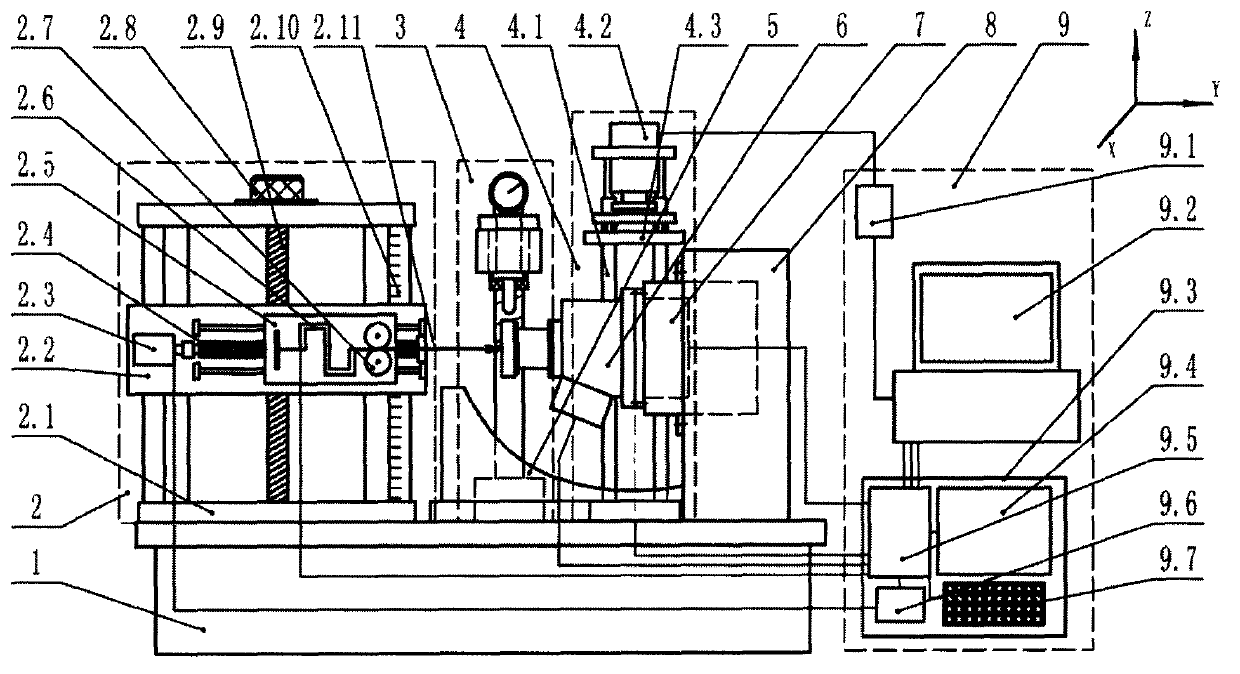

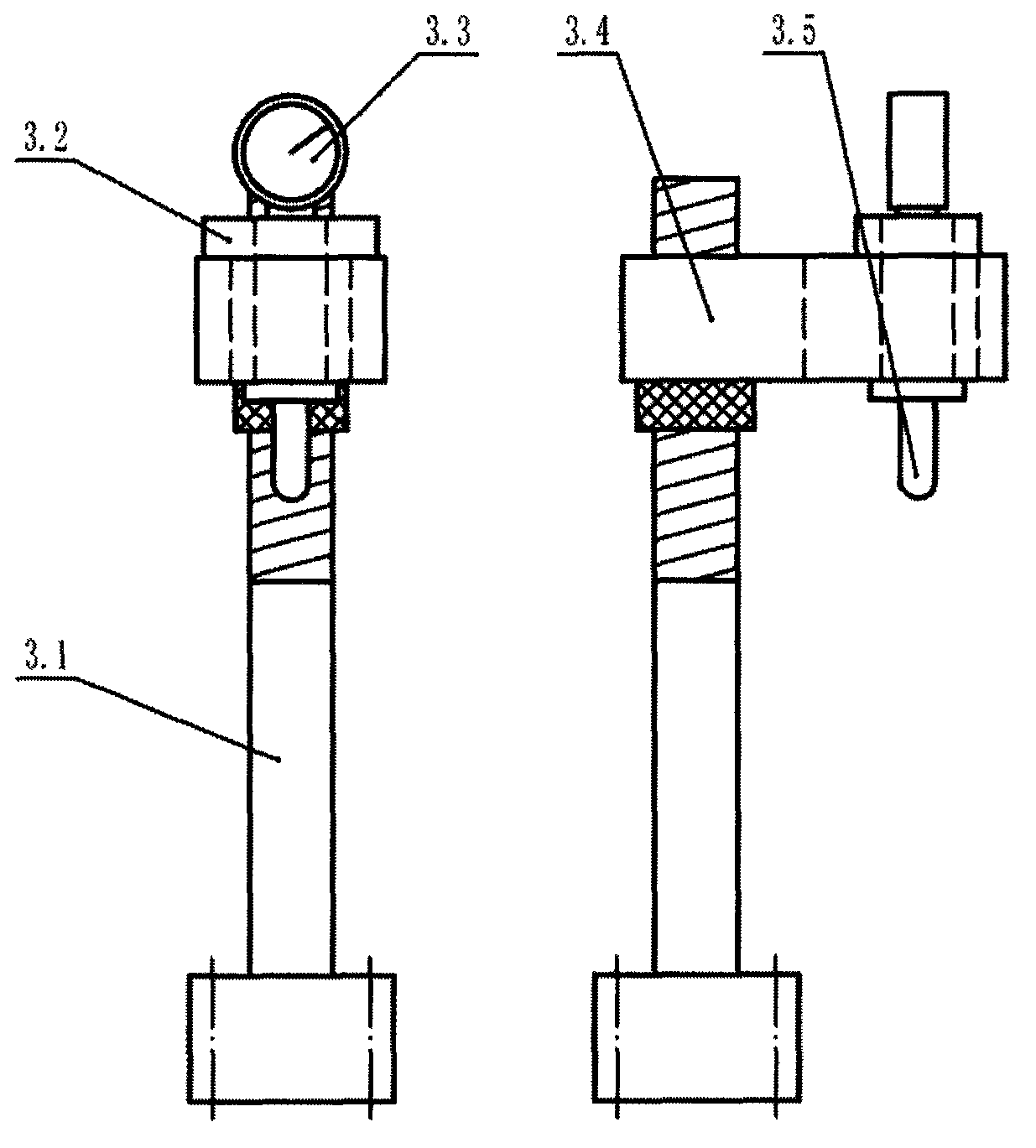

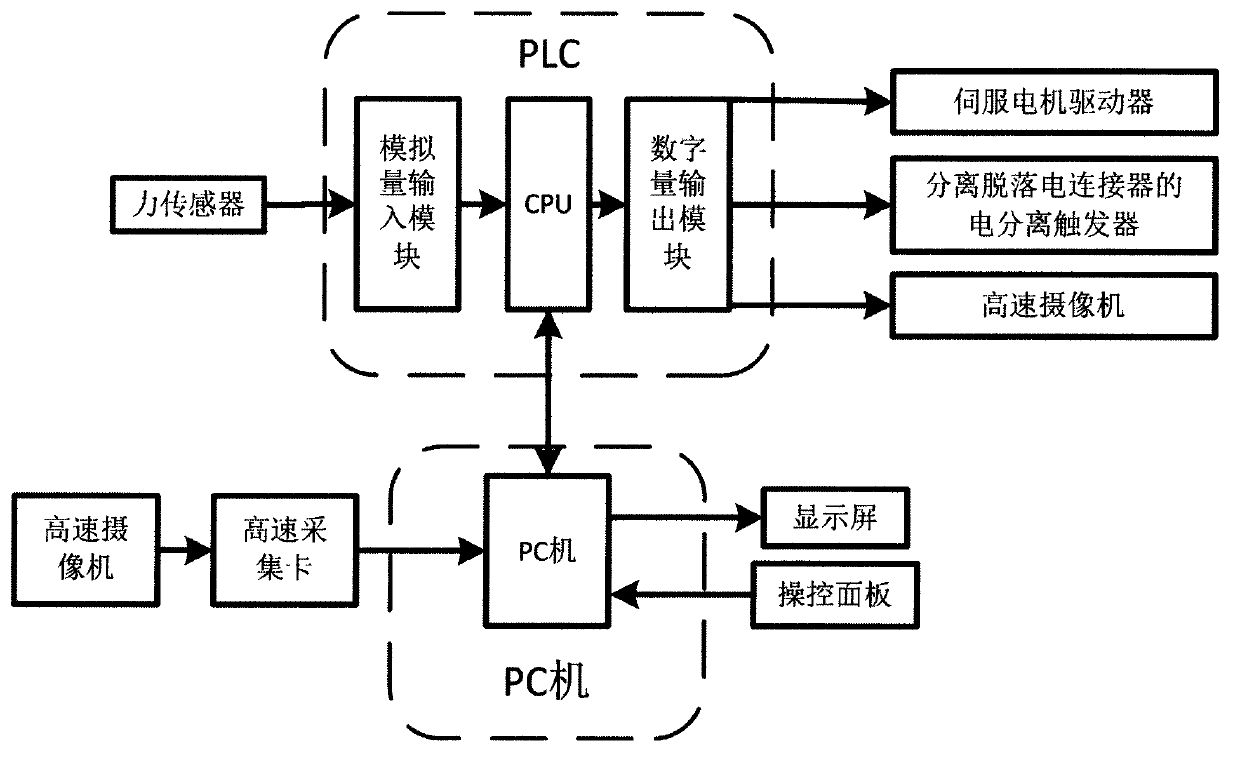

[0029] Such as figure 1 , 2 , Shown in 3, the composition and working principle of each unit of the present invention are as follows:

[0030] (1) Mechanical separation execution unit 2: This unit consists of column support 2.1, vertical slide 2.2, servo motor 2.3, horizontal screw 2.4, separation execution slide 2.5, force sensor 2.6, fixed pulley block 2.7, lifting adjustment hand wheel 2.8, It consists of a vertical lead screw 2.9, an angle scale 2.10 and a cable 2.11.

[0031] The servo motor 2.3 drives the horizontal lead screw 2.4 to realize the horizontal movement of the separation execution slide table 2.5 on the vertical slide table 2.2 to generate the separation driving force. At the same time, the force sensor 2.6 on the separation execution slide table 2.5 measures the pulling force suffered by the cable 2.11 in real time Adjust the position of the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com