Non-photosensitive polyimide passivation layer manufacturing method

A polyimide, non-photosensitive technology, applied in the production field of non-photosensitive polyimide passivation layer, can solve the problems of long soft-baking time and developing time, reducing equipment production efficiency, and increasing developer metal corrosion Risk and other issues, to eliminate the dependence of soft baking temperature and time, reduce high temperature baking time, and eliminate the effect of causing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

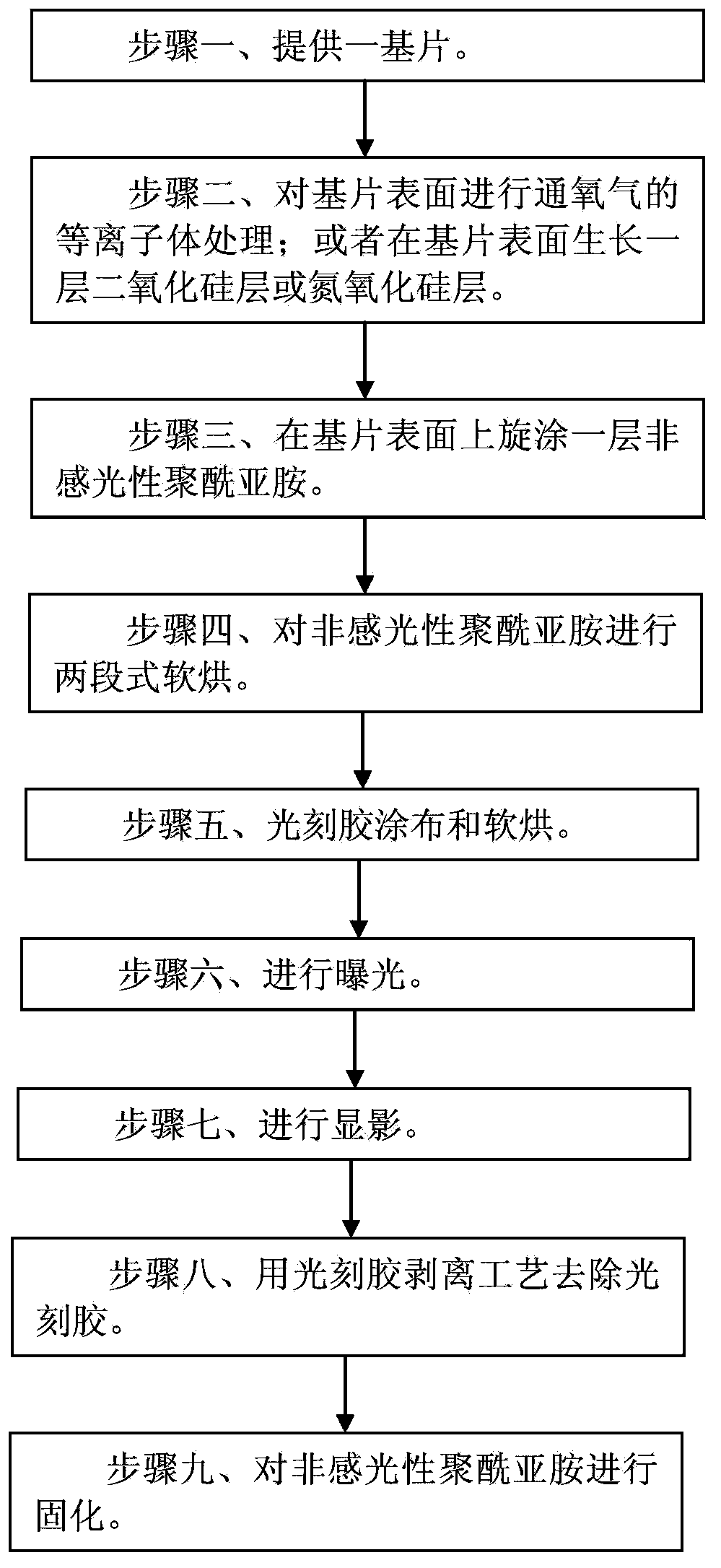

[0045] Such as image 3 Shown is the flow chart of the preparation method of the non-photosensitive polyimide passivation layer of the embodiment of the present invention; the preparation method of the non-photosensitive polyimide passivation layer of the embodiment of the present invention comprises the following steps:

[0046] Step 1, providing a substrate on which a non-photosensitive polyimide passivation layer needs to be fabricated on the surface.

[0047]A semiconductor device is formed in the substrate and the top metal wiring of the semiconductor device has been fabricated, and the non-photosensitive polyimide passivation layer is used to be formed on the top metal wiring and serve as the A passivation layer of a semiconductor device; or, a semiconductor device is formed in the substrate and the top metal wiring of the semiconductor device has been made, and a dielectric layer passivation layer is formed on the top metal wiring, so The non-photosensitive polyimide p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com