Back surface structure of reverse conducting IGBT and manufacturing method thereof

A backside structure, reverse conduction technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as reduced hole injection efficiency, increased manufacturing costs, wasted chip utilization, and reduced power consumption. , the effect of reducing the conduction voltage drop and avoiding the bounce phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

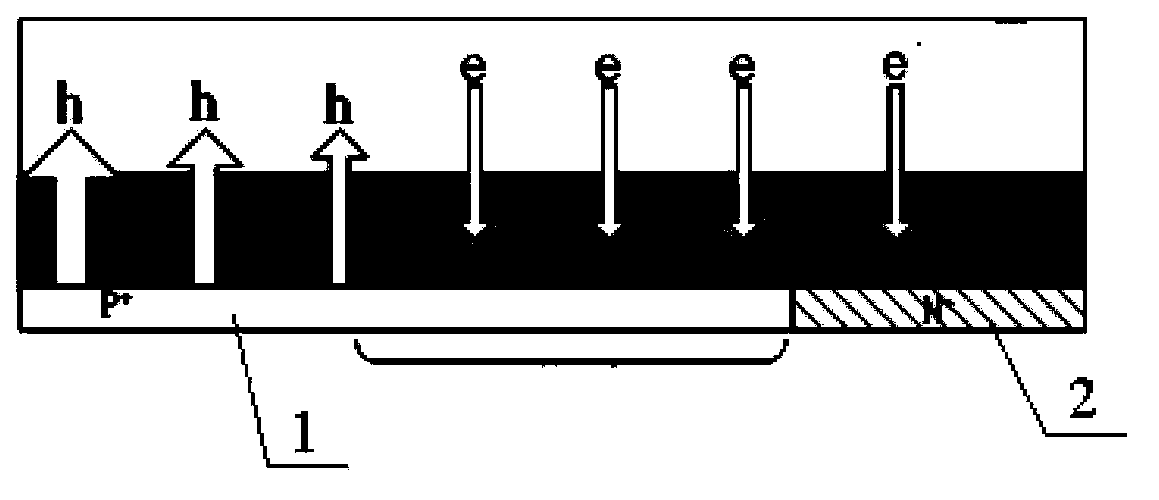

[0044] Such as image 3 As shown, the back structure of a reverse conduction IGBT provided in this embodiment includes: a drift region 100, a first N + Buffer layer 101, P + Collector area 102, N + Short circuit region 103 , insulating layer 104 and collector metal layer 105 . P + The collector region 102 is arranged on one side of the bottom of the drift region 100, N + The short circuit region 103 is set on the other side of the bottom of the drift region 100, P + Collector region 102 and N + The middle of the short-circuit region 103 is separated by a drift region 100, and the drift region 100 is low-doped N - area. P + collector region 102 through the first N + The buffer layer 101 is connected to the drift region 100 . Drift region 100 and first N + The buffer layers 101 are connected to the collector metal layer 105 through the insulating layer 104 . P + The collector region 102 is connected to the collector metal layer 105; N + The depleted part of the sho...

Embodiment 2

[0052] Such as Figure 8 As shown, the back structure of a reverse conduction IGBT provided in this embodiment includes: a drift region 200, a first N + Buffer layer 201, the second N + Buffer layer 206, P + Collector area 202, N + Short circuit region 203 , insulating layer 204 and collector metal layer 205 . P + The collector region 202 is arranged on one side of the bottom of the drift region 200, N + The short circuit region 203 is set on the other side of the bottom of the drift region 200, P + collector area 202 with N + The middle of the short-circuit region 203 is separated by a drift region 200, and the drift region 200 is low-doped N - area. P + collector region 202 through the first N + The buffer layer 201 is connected to the drift region 200 . Drift zone 200, first N + Buffer layer 201 and the second N + The buffer layers 206 are connected to the collector metal layer 205 through the insulating layer 204 . P + The collector region 202 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com