Hollow fiber type dialyzer liquid port protection cover automatic capping machine

A hollow fiber and dialyzer technology, applied in dialysis systems, suction equipment, etc., can solve the problems of inability to meet high-efficiency, high-quality and humanized production requirements, high labor intensity of operators, and poor consistency of cover tightness, etc., to meet high-efficiency The effect of high-quality humanization, good cap tightness and consistency, and reliable capping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

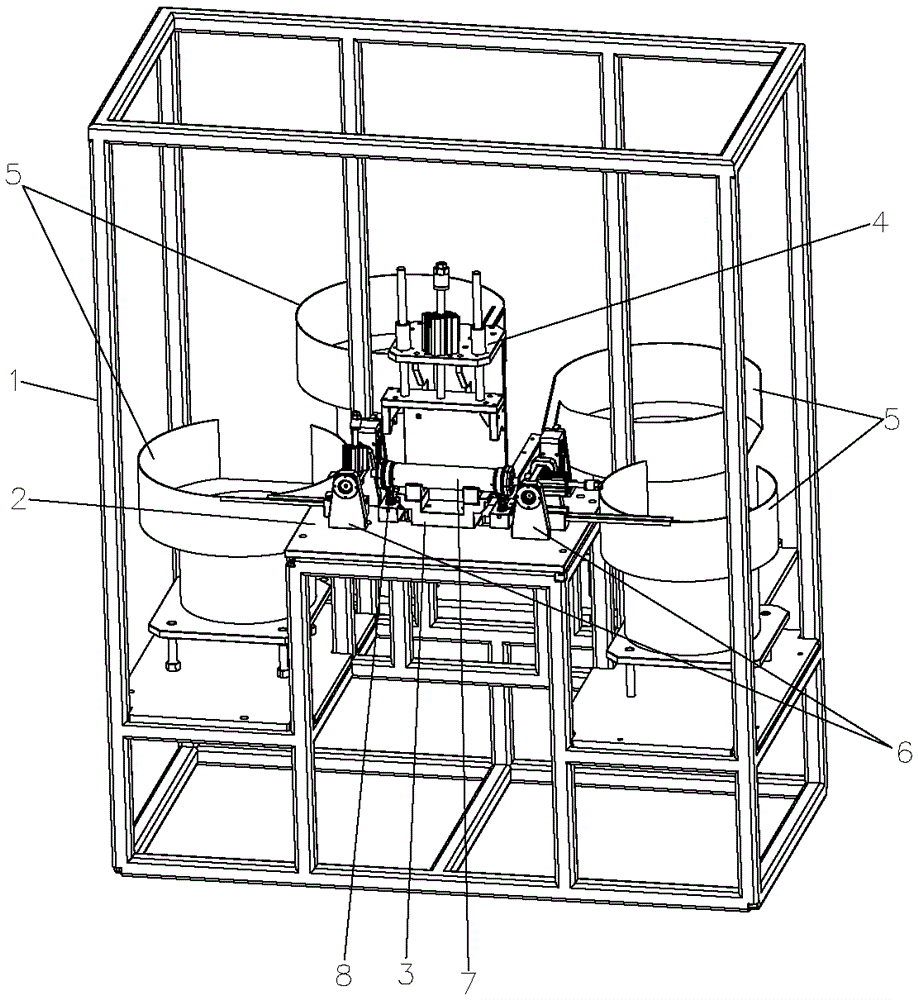

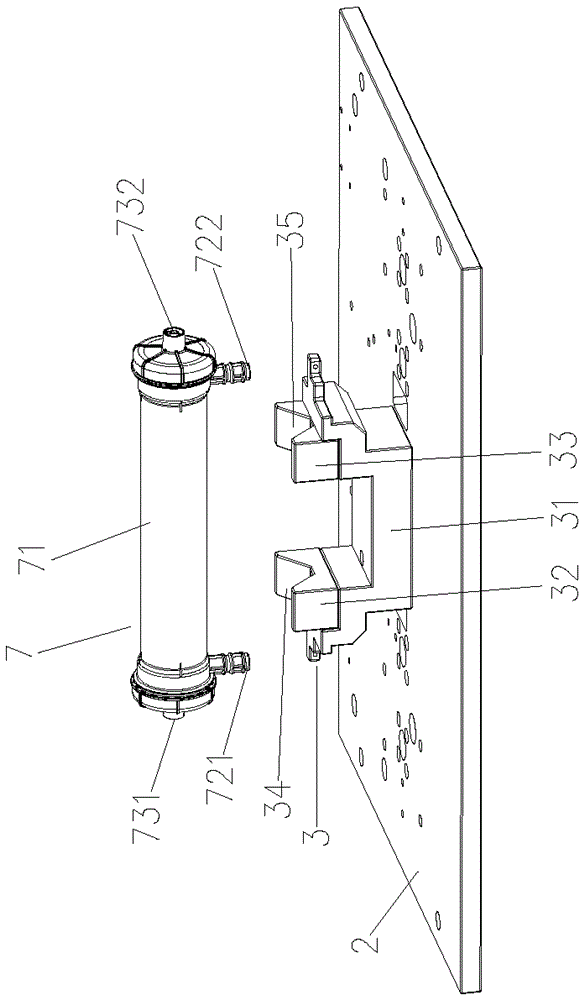

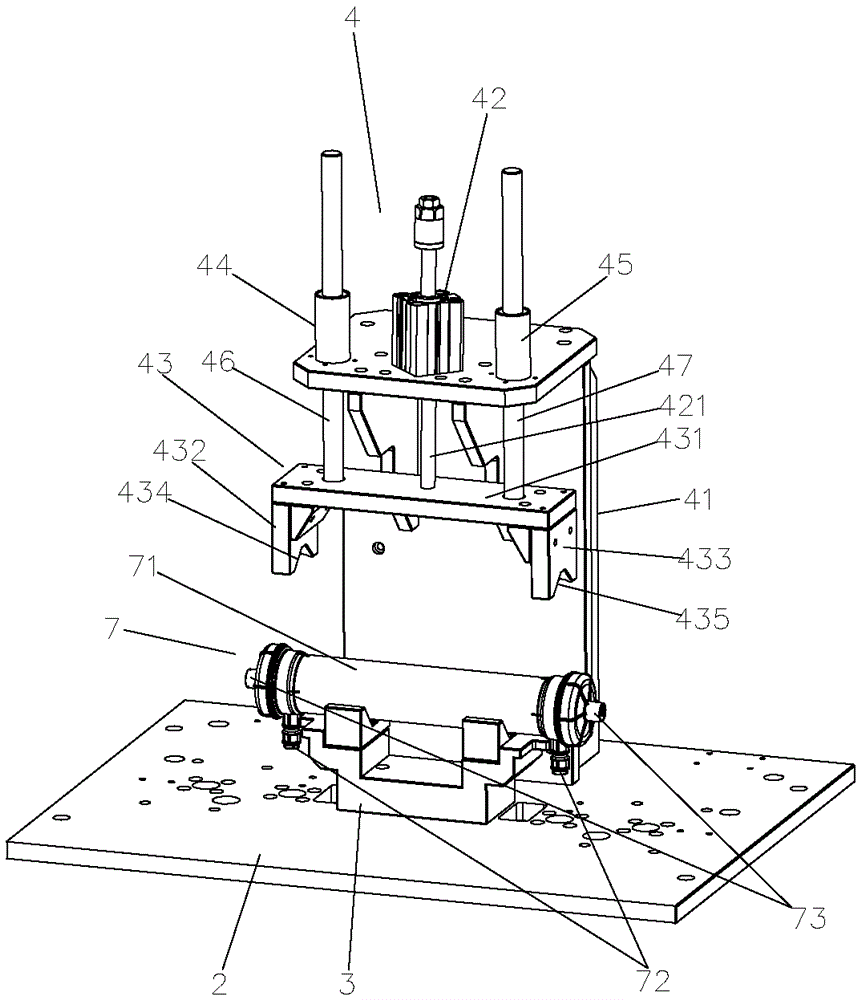

[0024] see figure 1 , 2 , the present invention hollow fiber type dialyzer liquid port protective cover automatic capping machine, comprises frame 1 and the bottom plate 2 that is fixedly installed in the front part of frame 1, and the middle part of bottom plate 2 is fixedly supported support platform 3, and this support platform 3 It consists of a base 31 and two left and right support blocks 32, 33 fixedly mounted on the base. The upper surface of the support blocks 32, 33 is provided with V-shaped support ports 34, 35 matching the middle shell 71 of the dialyzer 7. .

[0025] see figure 1 , 3 , the top of the supporting platform 3 is provided with a compacting device 4, the compacting device 4 consists of a stand 41 fixed on the bottom plate 2 behind the supporting platform 3, a cylinder 42 fixed on the vertical stand 41 downwards, and a cylinder 42, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com