Preparation method for Pd/Fe/PVDF (Polyvinylidene Fluoride).Al2O3 catalyst based on modification

A matrix modification and catalyst technology, applied in the fields of chemical industry and catalyst, can solve problems such as application limitations, difficult contact infiltration, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] 1 Preparation process of PVDF·Al2O3 carrier

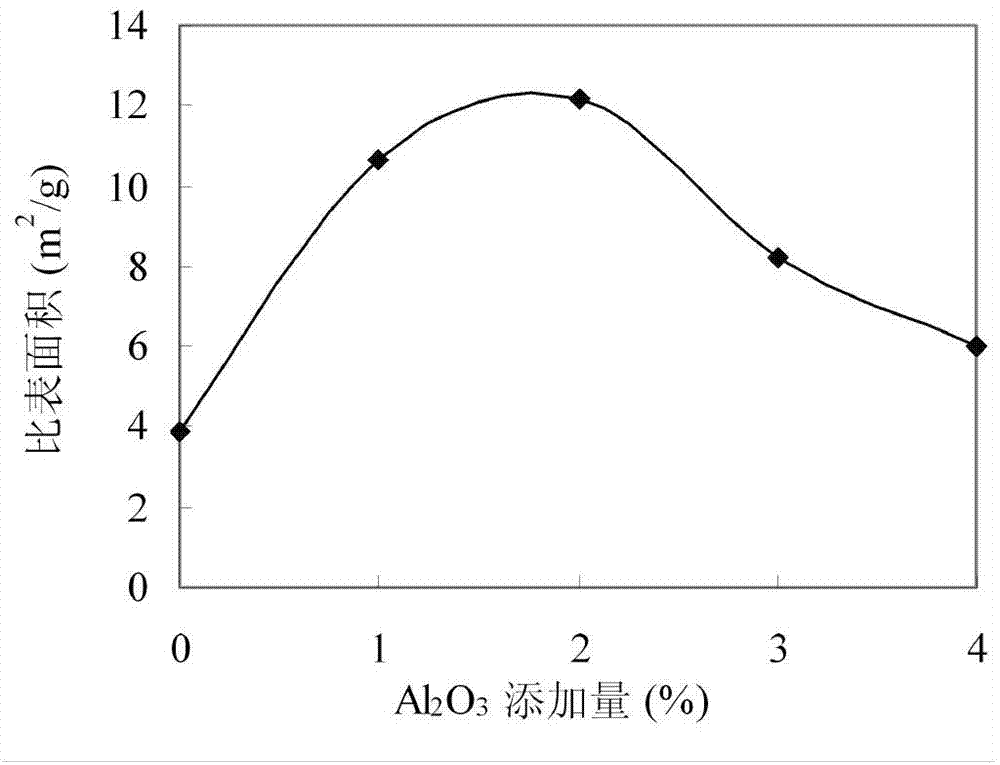

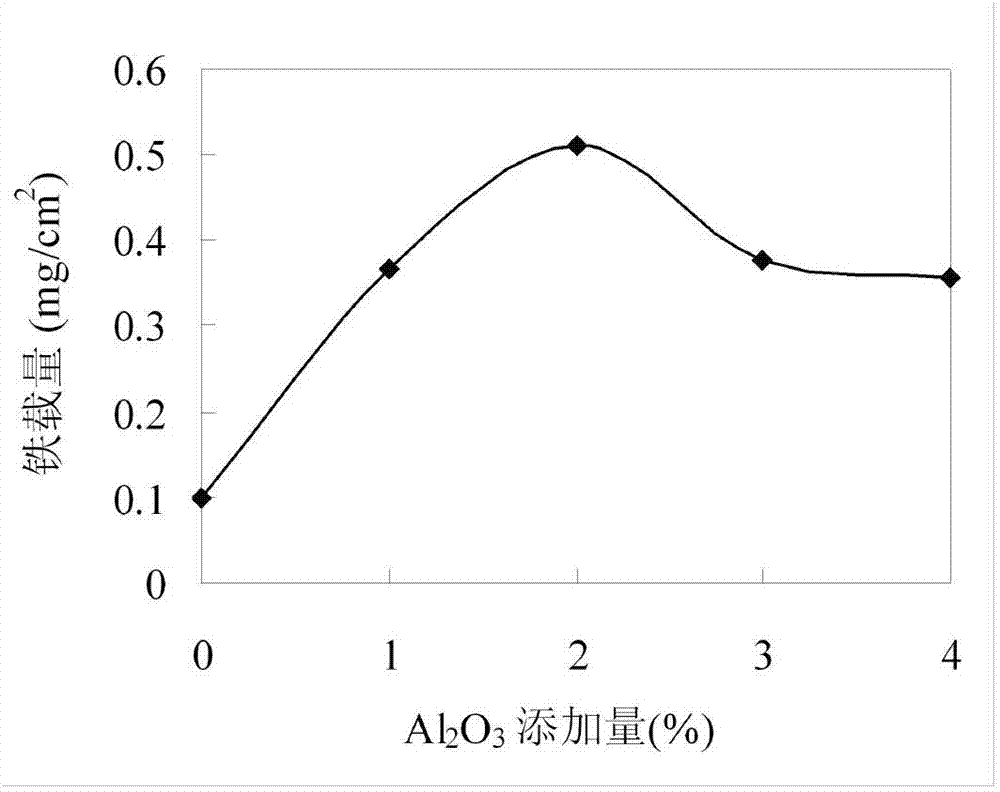

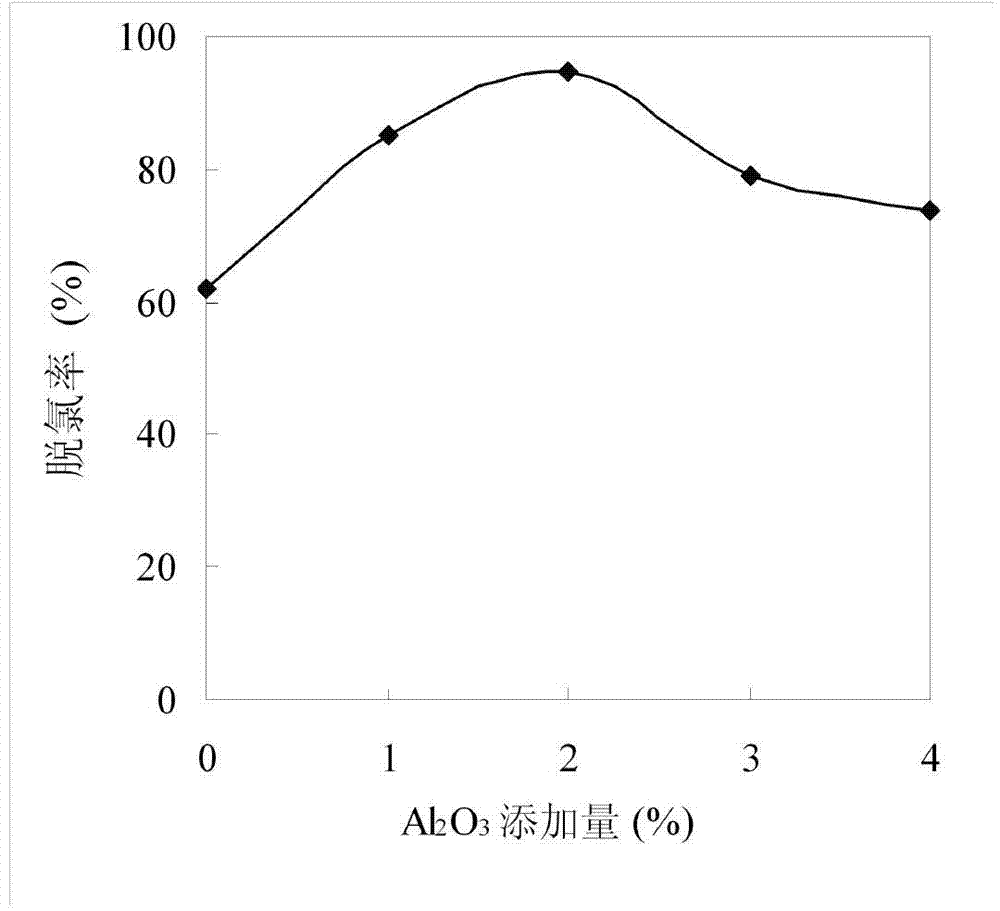

[0026] In the experiment of loading nano-Pd / Fe with PVDF commercial film, it was found that the mechanical properties of the modified PVDF commercial film decreased. . Al2O3-modified PVDF supports were prepared in experiments, and the addition amounts of nano-Al2O3 were 0%, 1%, 2%, 3%, and 4%, respectively, expressed as PVDF-0, PVDF-1, PVDF-2, PVDF-3, PVDF-4, carrier composition and preparation conditions are shown in Table 1.

[0027] Table 1 Carrier composition and preparation conditions

[0028]

[0029] Dissolve a certain amount of polyvinylidene fluoride powder in N,N-dimethylacetamide solvent, keep stirring until completely dissolved, add nano-aluminum oxide (Al2O3) particles to it, add dispersant sodium hexametaphosphate ( (NaPO 3 ) 6 ) to promote the uniform dispersion of particles, adding pore-forming agent polyvinylpyrrolidone (PVP) to make the prepared carrier have certain pores, when Al2O3 is uniformly mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com