Breeze electrical dust remover

An electrostatic precipitator and breeze technology, applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of large average migration distance of dust, easy production of secondary dust, affecting dust removal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

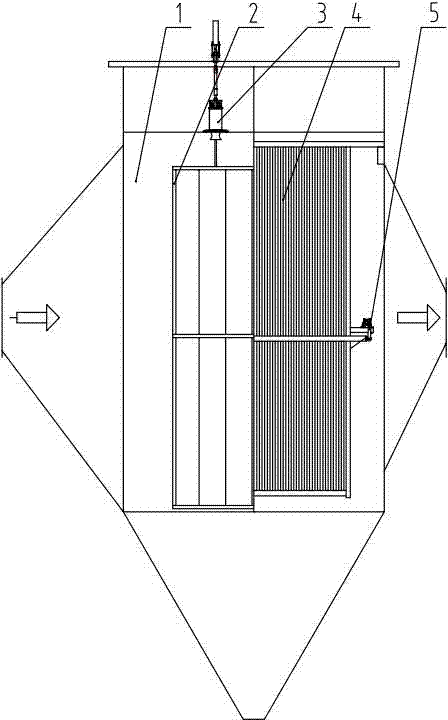

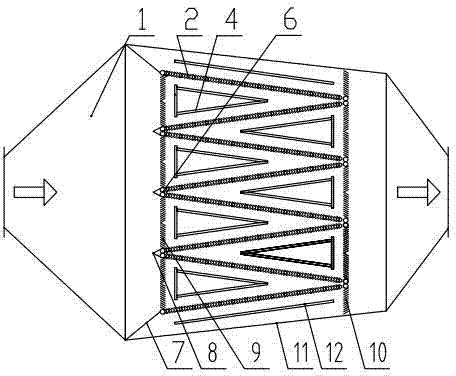

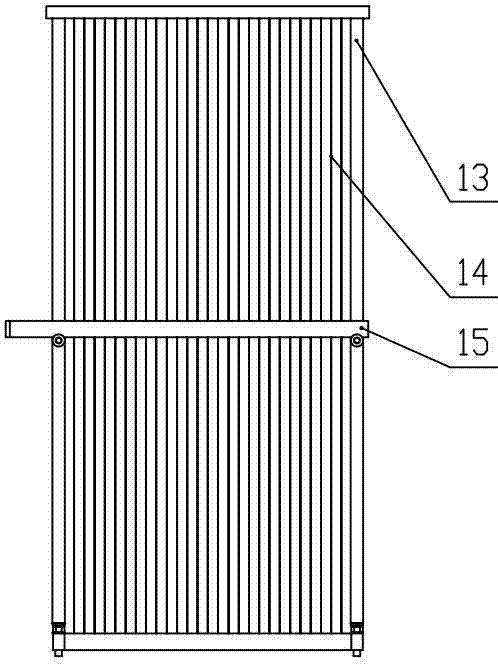

[0017] figure 1 and 2 Among them, a micro-wind electrostatic precipitator includes a housing 1 , a dust collection system 2 , a dust collection and rapping device 3 , a discharge system 4 and a discharge rapping device 5 . The housing 1 includes an inlet port and an outlet port, and the dust collection system 2 and the discharge system 4 are arranged in the inner cavity of the housing 1 . The dust collection and rapping device 3 is arranged at the inlet end of the housing 1 . The discharge rapping device 5 is arranged on the top of the discharge system 4. Such an arrangement structure can avoid the shortage of air leakage at the closed point caused by side rapping in the prior art. The dust collection system 2 includes several groups of anode plates. Adjacent groups of anode plates are staggered at an angle and connected end-to-end. A plurality of closed points 6 are formed at the inlet end and the outlet end of the housing 1 . The discharge system 4 includes several groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com