Washing water collection device of wet-type electric demister

A collection device, demister technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of absorption tower water balance damage, system paralysis, slurry tank liquid level rise, etc., to achieve a small footprint , save water resources, and effectively use the site space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

[0049] Such as Figure 1-Figure 5 As shown, it is a schematic structural diagram of the flushing water collection device of the wet electrostatic precipitator proposed by the present invention, and the specific structure is as described in the content of the invention, and will not be repeated here. Combined with its structure, its principle will be analyzed and explained below.

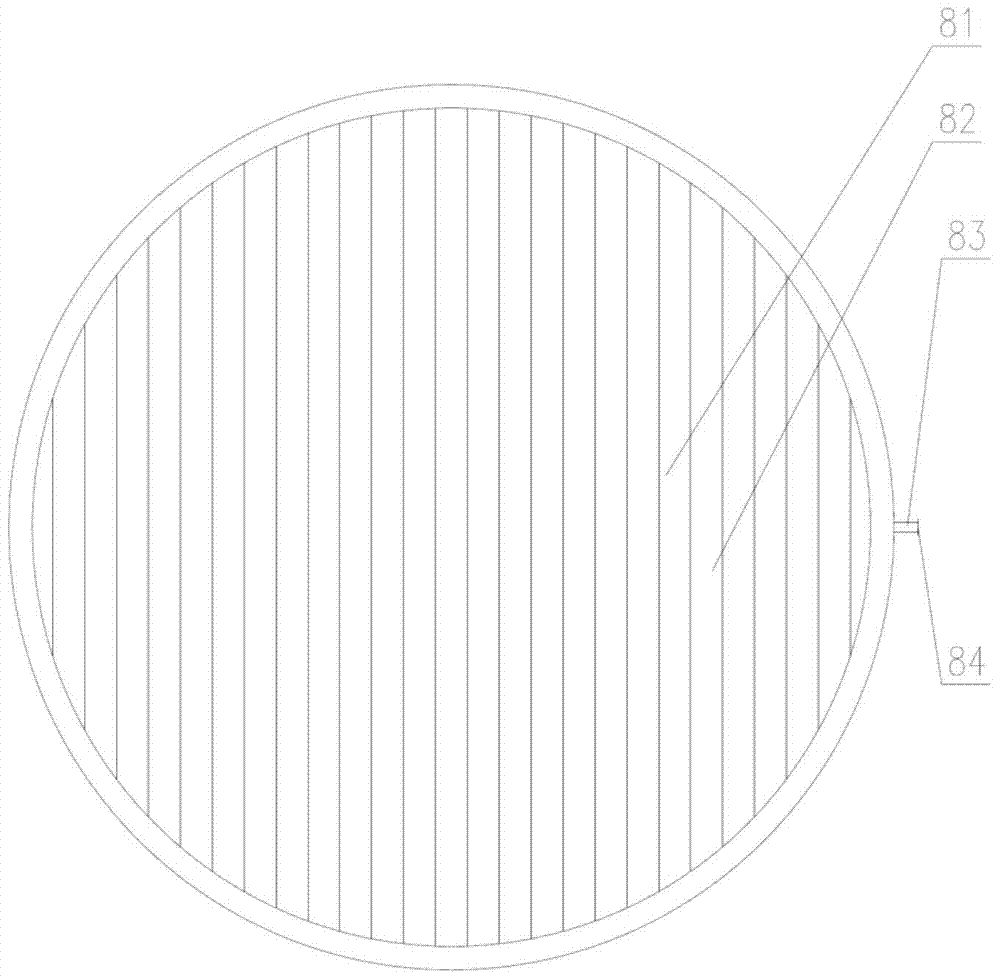

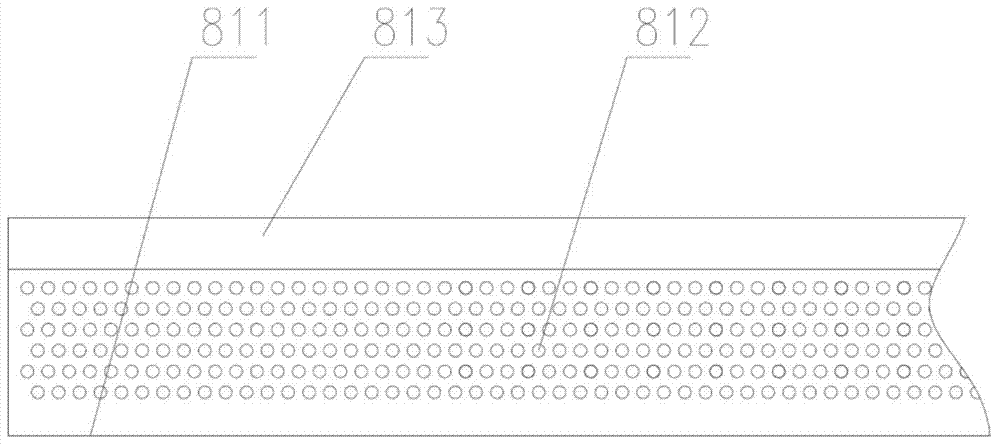

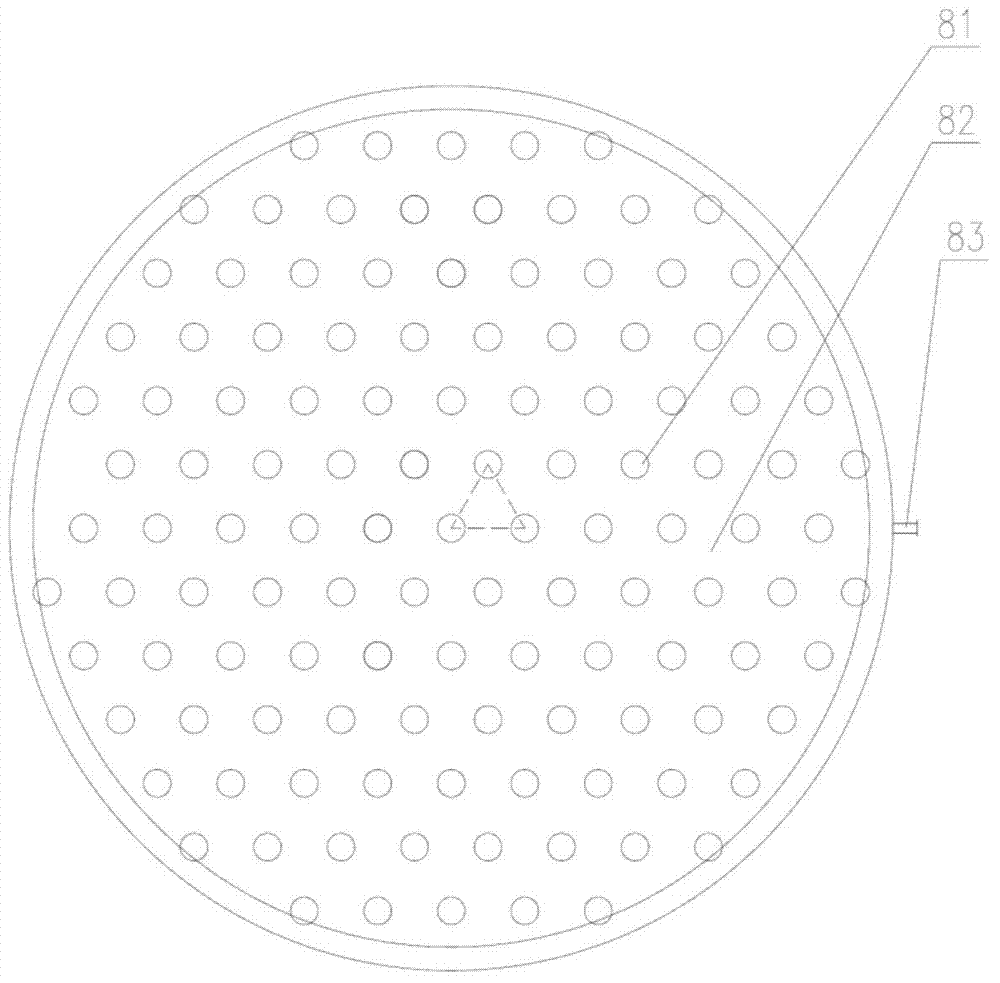

[0050] combine figure 1 , figure 2 , is the first implementation form of the channel base end 811 part of the flushing water collecting device proposed by the present invention. In this embodiment, the base end 811 of the channel is a horizontal cuboid, and the cuboids are arranged in parallel, so that the chassis of the flushing water collection device is divided into a gas channel element 81 and a liquid channel element 82 . More p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com