Squid shredding machine

A technology of shredding machine and squid, which is applied in the direction of metal processing, etc., can solve the problems of messy and uneven squid shreds, slow shredding speed, and inability to directly process squid shredders, so as to protect food hygiene, improve production efficiency, and save energy. To unfreeze the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings and embodiments.

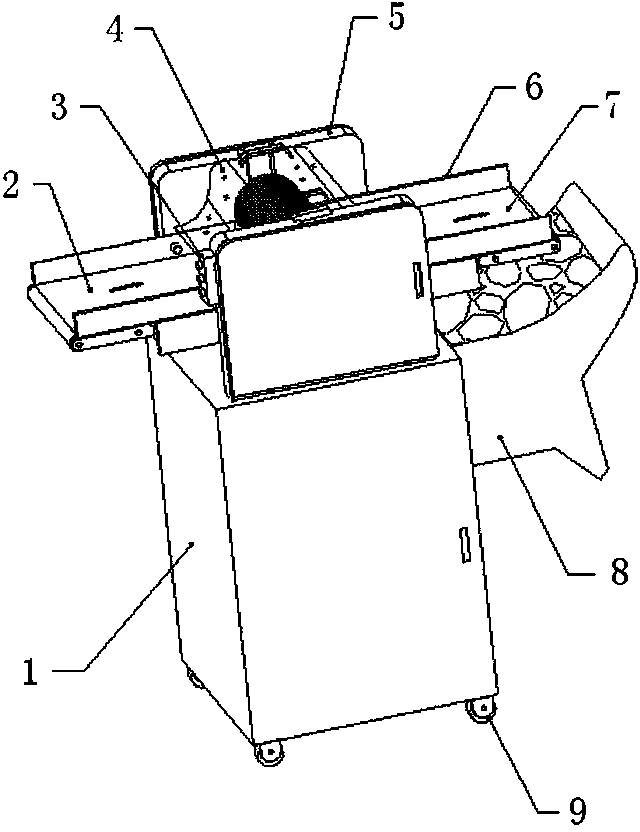

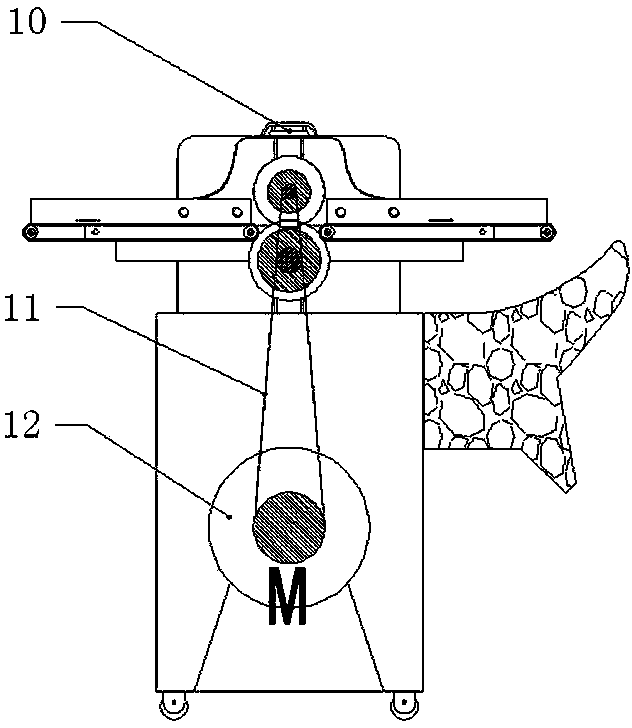

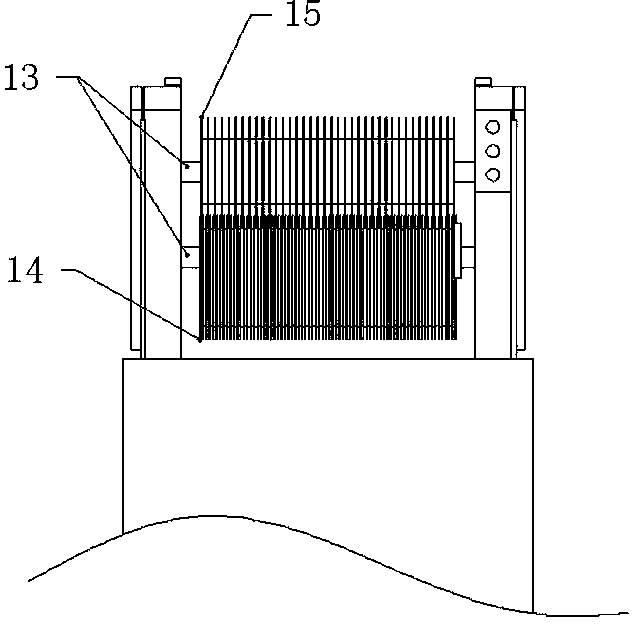

[0014] The squid shredder of the present invention includes a chassis 1, a feeding conveyor belt 2, a control button 3, a cover plate 4, an assembly plate 5, a baffle plate 6, a discharge conveyor belt 7, a storage hopper 8, a caster 9, and a fixing pin 10 , Belt 11, motor 12, rotating shaft 13, supporting wheel 14 and slicing group 15. The case 1 is a hollow rectangular structure, and the case 1 is formed by bending and welding cold plates. The bottom of the case 1 is equipped with casters 9 for easy movement. There are detachable assembly boards 5 on the left and right sides of the top. The two assembly boards 5 form an assembly line. The slicing group 15 is horizontally fixed between the assembly boards 5 through the rotating shaft 13. The slicing group 15 is made of multi-layer SUS316 stainless steel blades. Combined, the gap of the slice group 15 can be adjusted. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com