Mold and production method for producing absorbable skin suturing nail

A technology of suture staples and molds, which is applied in the field of molds for absorbable skin suture staples, which can solve the problems of lower product production efficiency, complex staple parts, and lower production efficiency, so as to save valuable space, improve utilization rate, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

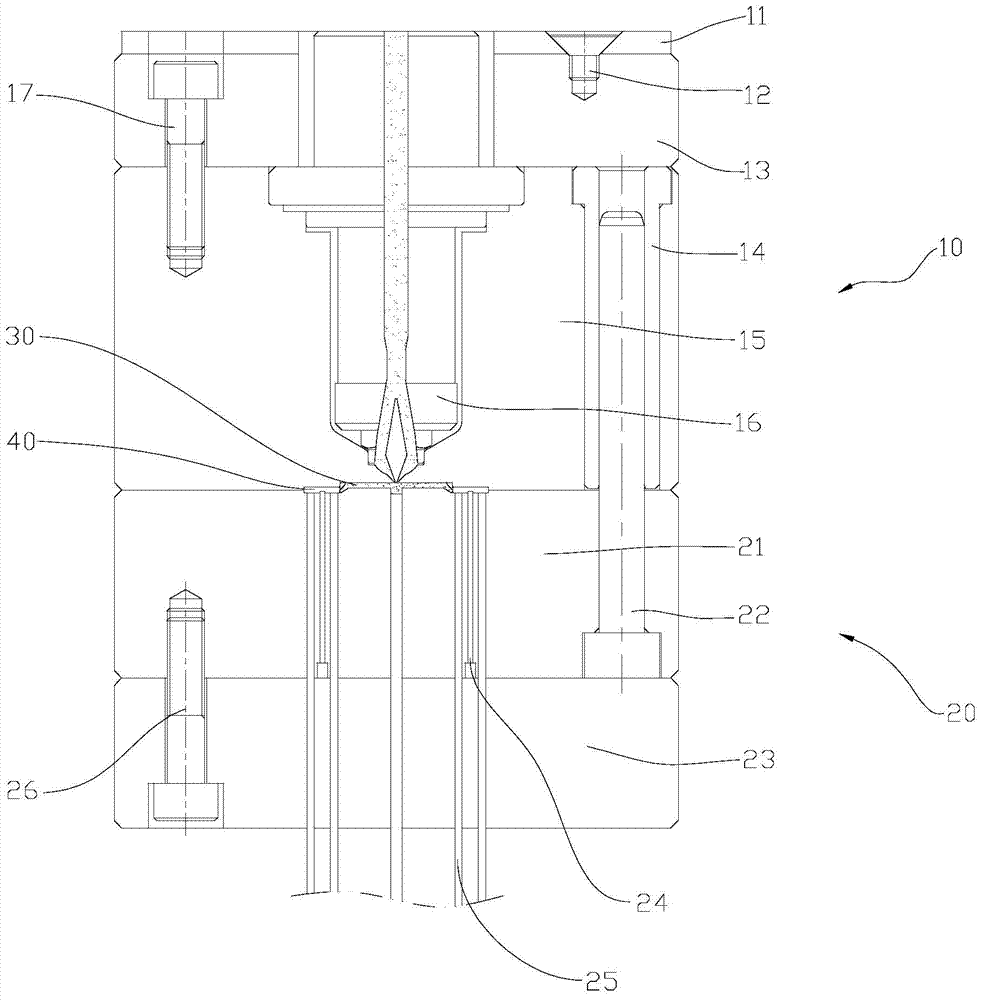

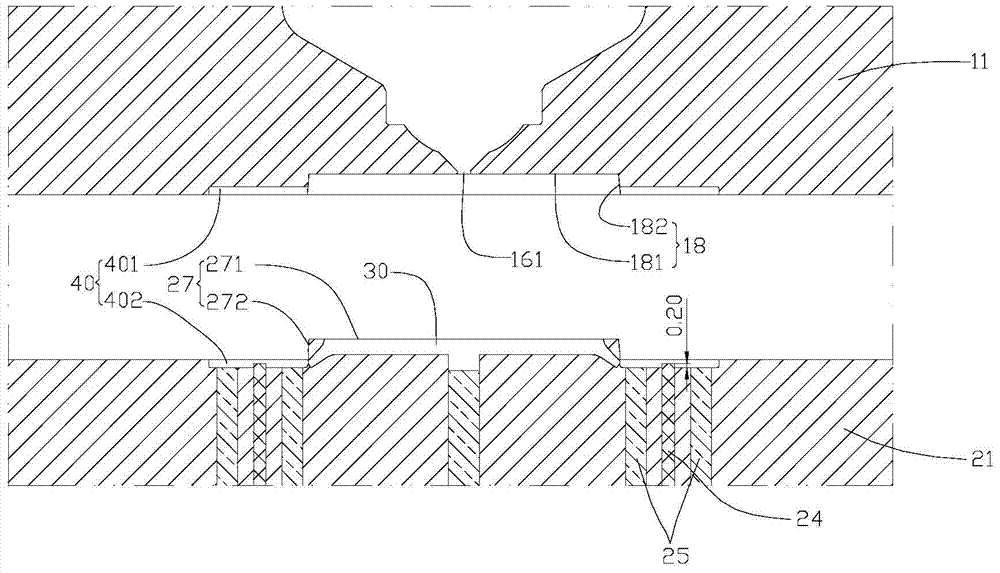

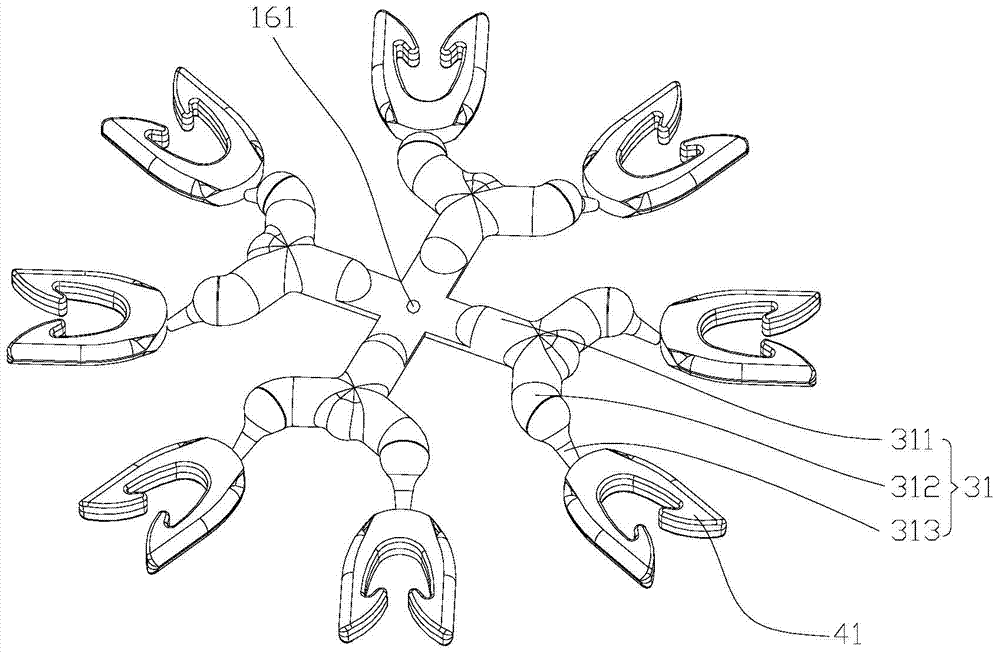

[0030] Referring to the accompanying drawings, the absorbable skin staple forming mold provided by the embodiment of the present invention includes a fixed mold assembly 10 and a movable mold assembly 20;

[0031] The fixed mold assembly 10 includes a heat insulation plate 11 , a top plate 13 , an upper mold plate 15 , a hot runner 16 , a guide sleeve 14 , a first locking piece 12 , and a second locking piece 17 . The heat insulation board 11 is fixed on the upper surface of the top plate 13 by the first locking member 12, the upper mold plate 15 is fixed on the lower surface of the top plate 13 by the second locking member 17, and the guide The sleeves 14 are distributed on the 4 corners of the upper mold plate 15 . The movable mold assembly 20 includes a lower mold plate 21 , a supporting plate 23 , an insert pin 24 , a guide post 22 , a third locking member 26 and a push rod 25 . The supporting plate 23 is fixed on the lower surface of the lower mold plate 21 by the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com