Belt loader telescopic nose for coal mines

A technology of reloading machine and telescopic machine, which is applied in the direction of conveyors, slitting machines, conveyor objects, etc., which can solve the problems of insufficient belt tension stroke and difficulty in belt deviation adjustment, and achieves high practical value, compact structure, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

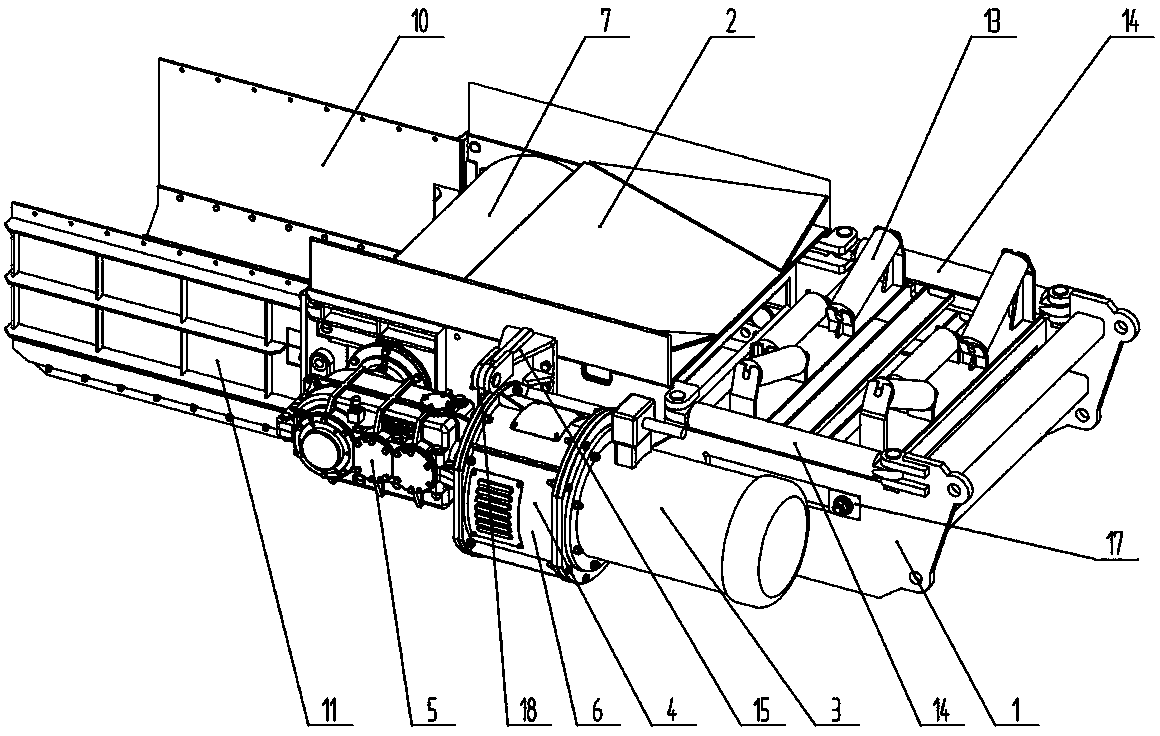

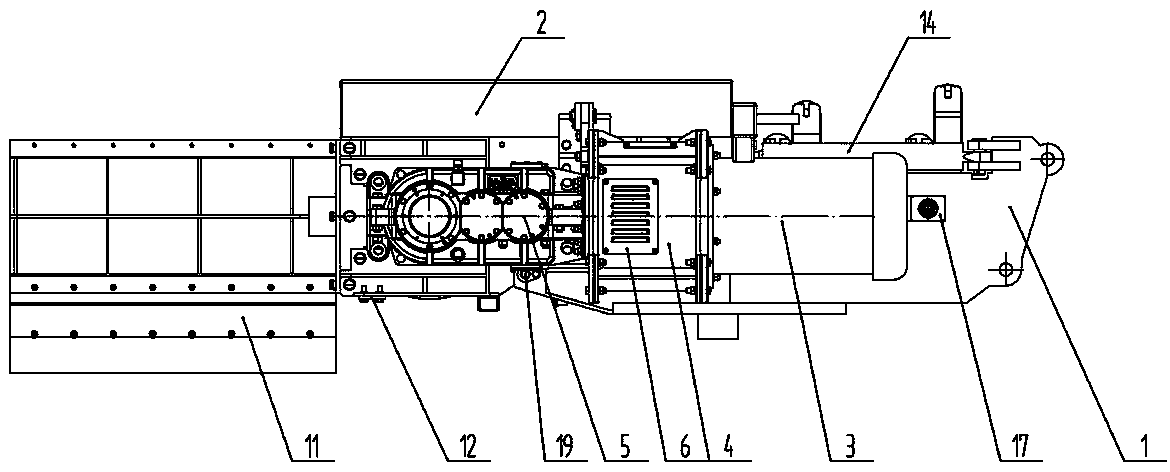

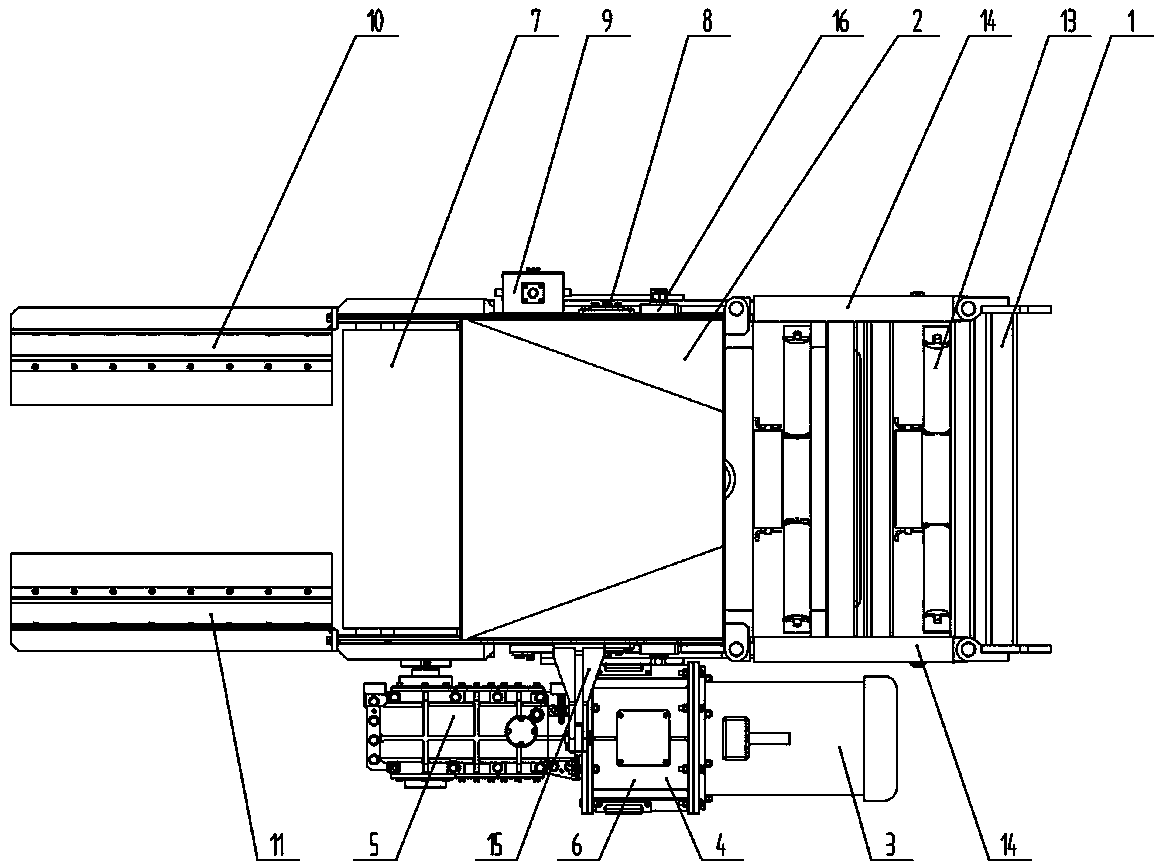

[0013] The present invention will be further described below in conjunction with accompanying drawing:

[0014] The telescopic head of the belt loader used in coal mine mainly includes: fixed frame 1, sliding frame 2, motor 3, hydraulic coupling 4, reducer 5, coupling cover 6, driving drum 7, belt pressing drum 8, oil supply tank 9 , coal retaining plate 10, 11, cleaner 12, trough roller 13, tension cylinder 14, hanger 15, front and rear sliders 16, 17, lug plate 18, fixed cover pin 19.

[0015] The rear part of the retractable machine head is a fixed frame 1, and the front of the fixed frame 1 is a sliding frame 2. The fixed frame is designed with a front guide rail and a rear chute. The sliding frame 2 is supported on the front of the fixed frame by a front slider 16 and a rear slider 17. On the guide rail and in the rear chute; the fixed frame 1 and the sliding frame 2 are fixed by the fixed cover pin 19; the two sides of the sliding frame 2 are the first connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com