Environment-friendly foaming agent composition

A composition and foaming agent technology, which is applied in the field of foaming agent application, can solve the problems of high energy consumption, high thermal conductivity, and high GWP value of the whole machine, and achieve the effect of reducing thermal conductivity, small thermal conductivity, and low GWP value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

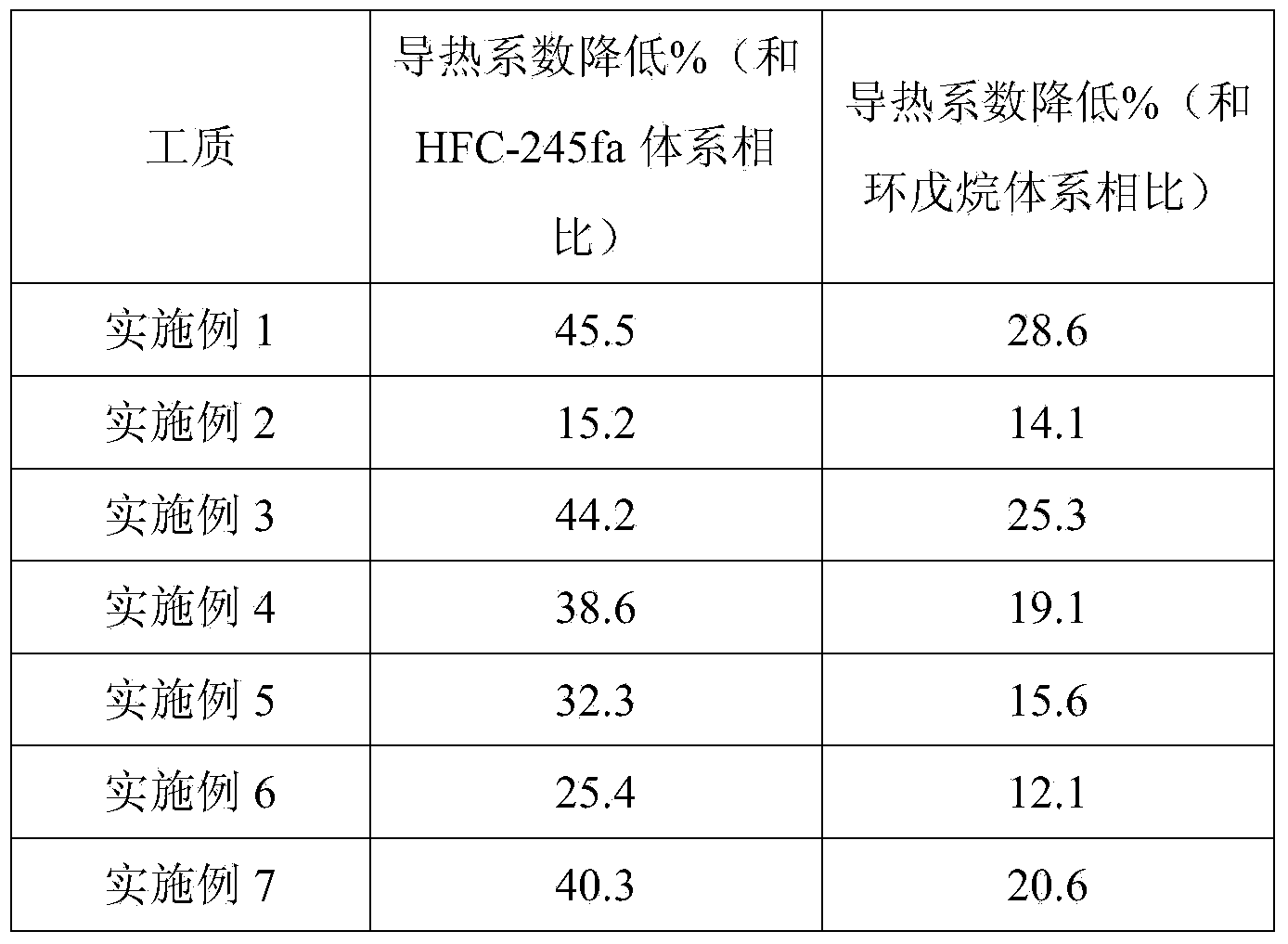

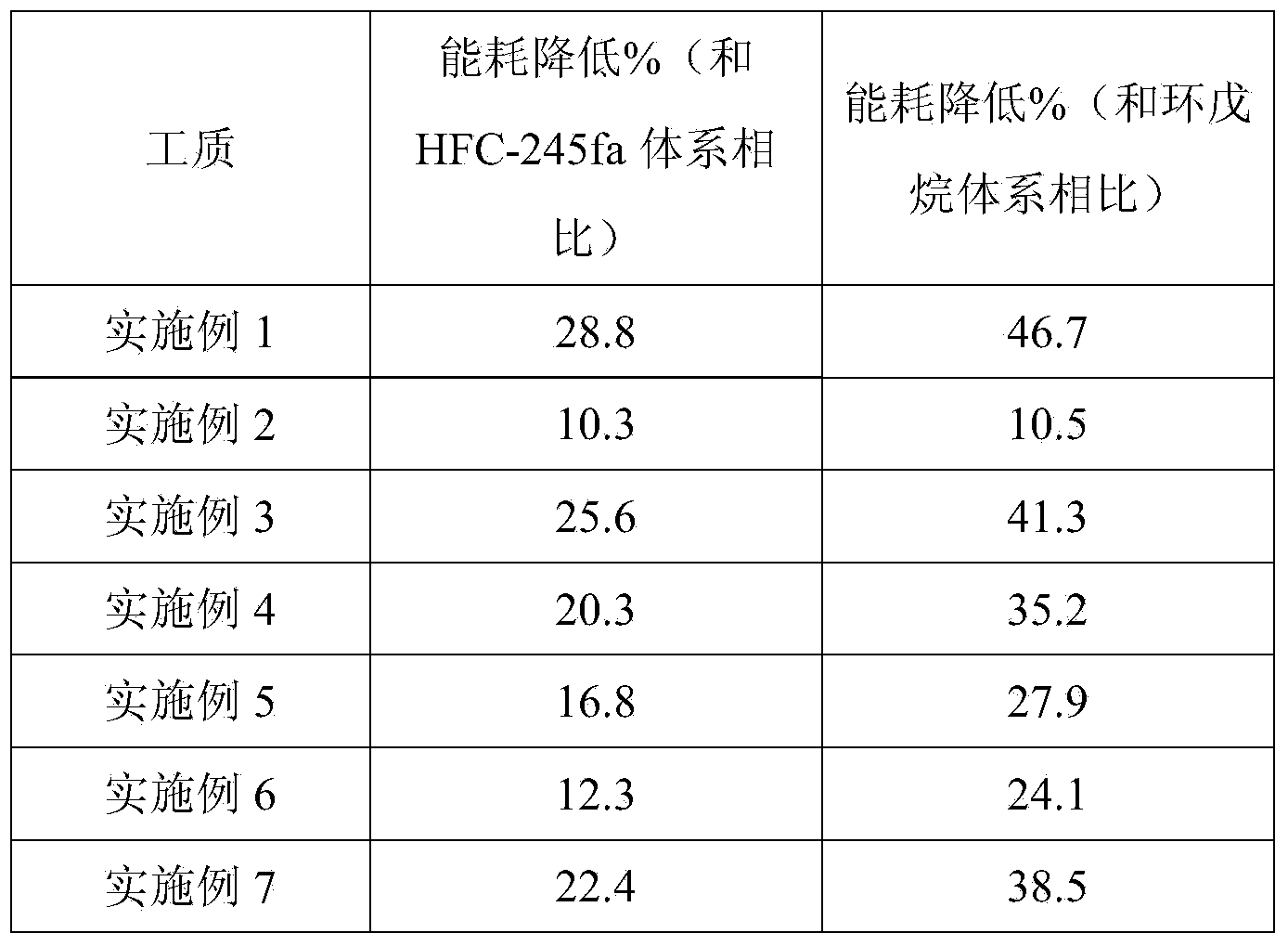

Examples

Embodiment 1

[0033] Mix 600 grams of HFC-245fa and 400 grams of HFO-1233zd in a steel cylinder to obtain an environmentally friendly foaming agent. The mass percentage of HFC-245fa is 60%, and the mass percentage of HFO-1233zd is 40%. Use automatic comparison The boiling point tester can see that there is an azeotrope between HFC-245fa and HFO-1233zd. When HFO-1233zd with a high boiling point is added to the cylinder containing HFC-245fa, the temperature in the cylinder will drop from the equilibrium temperature, which proves that there is An azeotrope is formed with a boiling point of 16.8°C.

Embodiment 2

[0035] Mix 990 grams of HFC-245fa and 10 grams of HFO-1233zd in a steel cylinder to obtain an environmentally friendly foaming agent. The mass percentage of HFC-245fa is 99%, and the mass percentage of HFO-1233zd is 1%. The boiling point is determined with the same Example 1, the boiling point is 15.4°C.

Embodiment 3

[0037] Mix 700 grams of HFC-245fa and 300 grams of HFO-1233zd in a steel cylinder to obtain an environmentally friendly blowing agent, the mass percentage of HFC-245fa is 70%, the mass percentage of HFO-1233zd is 30%, and the boiling point is determined with the same Example 1, the boiling point is 16.4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com