Center filament tensioning device for steel strand monofilament spraying

A technology for tensioning devices and steel strands, which is applied in rope-making auxiliary devices, textiles and papermaking, textile cables, etc., and can solve the problems of increased production costs, high maintenance and repair costs, and large floor space of epoxy steel strands and other issues, to achieve the effect of being conducive to market competition, occupying a small space, occupying a small area, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

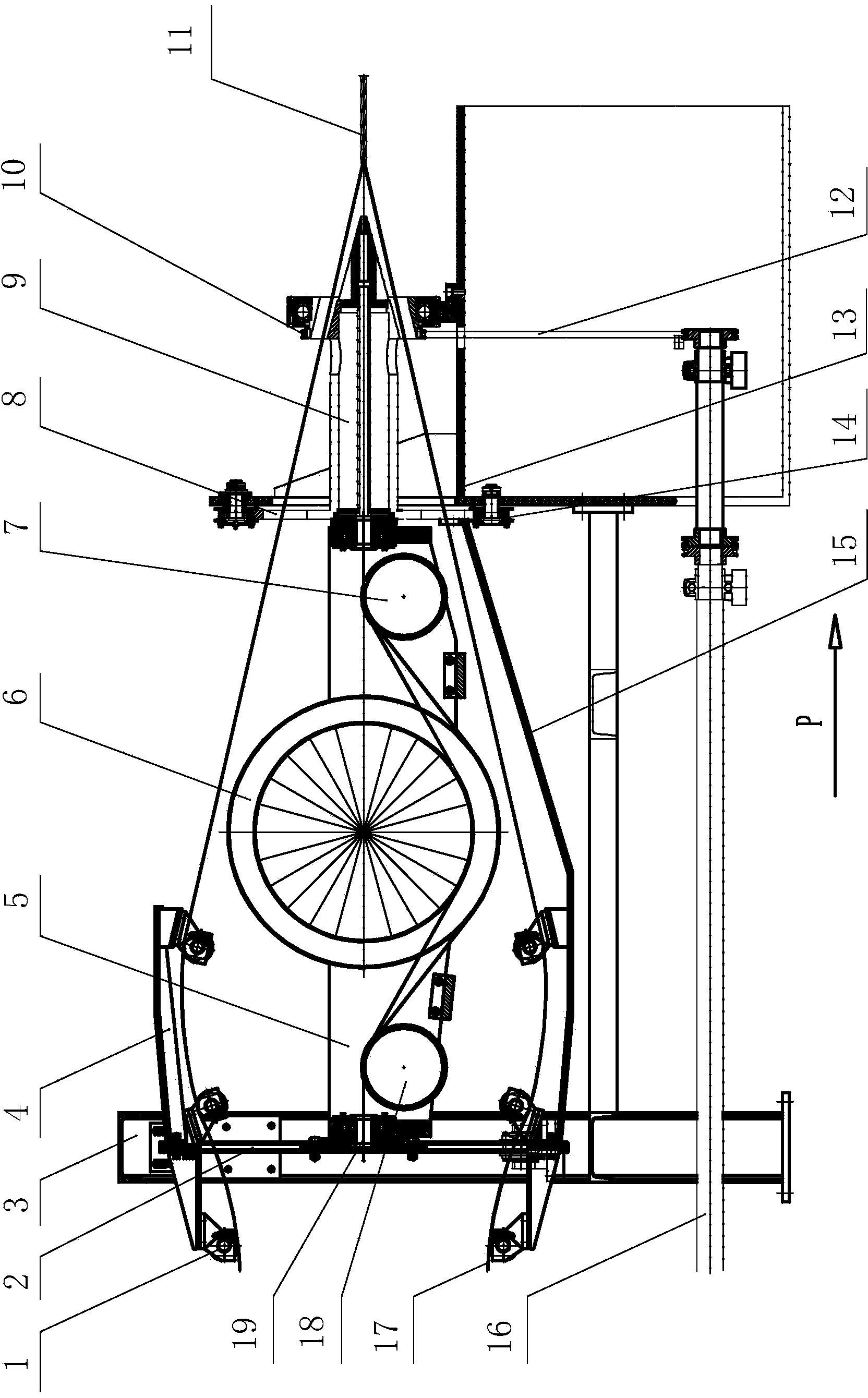

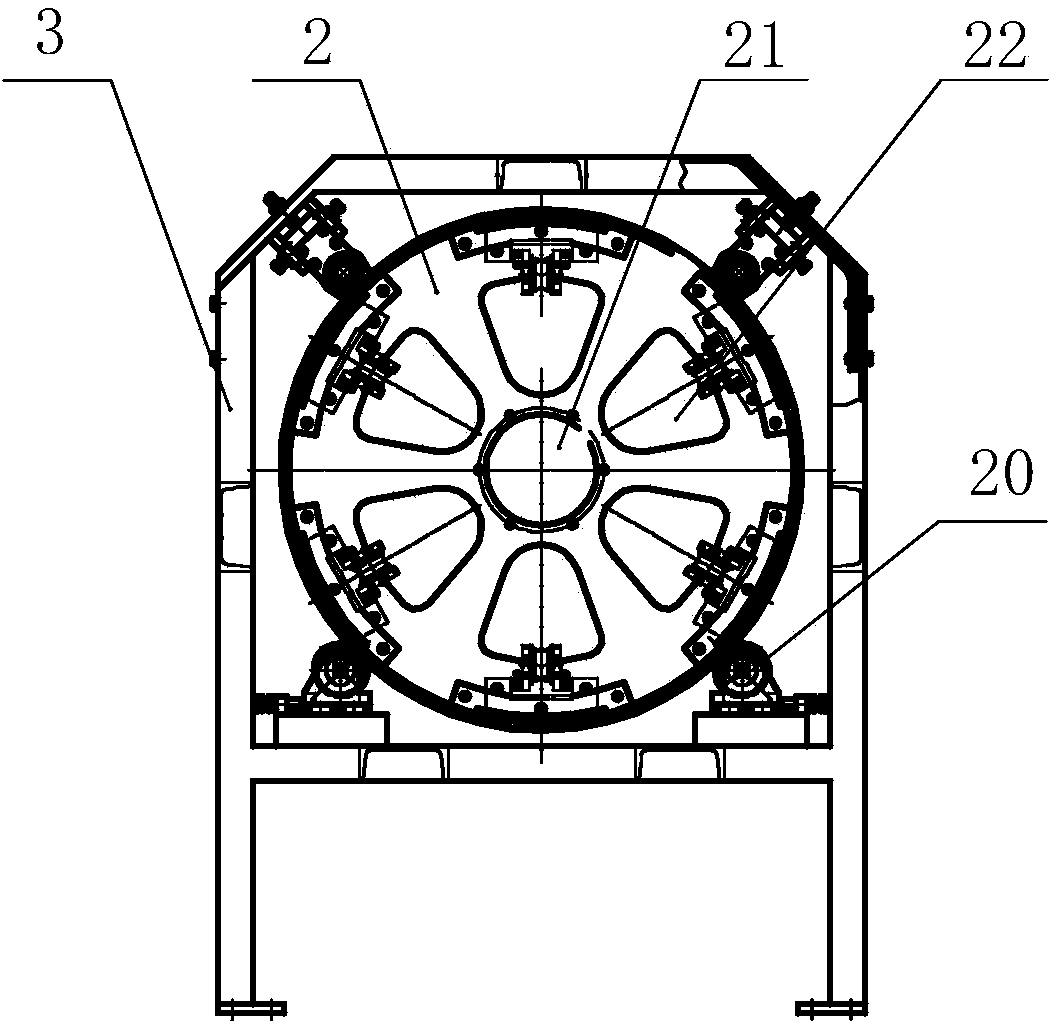

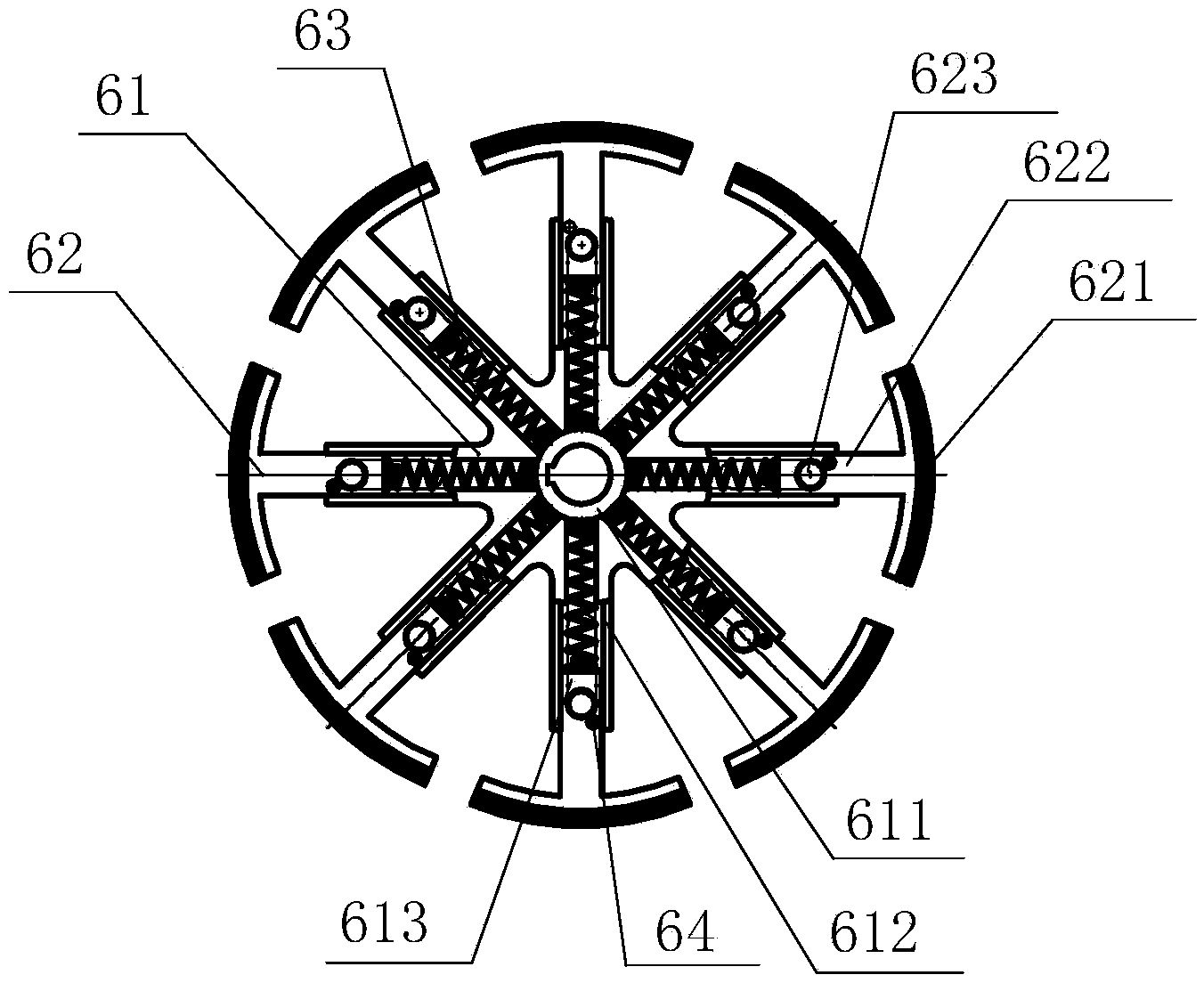

[0030] Embodiment 1: A steel strand monofilament spraying center wire tensioning device, including a door frame 3, an inner guide wheel I18, an inner guide wheel II7, a center wire tension wheel 6, a tension wheel bracket 5, a support frame 13, Transmission shaft 16, synchronous sprocket 10 and large tray 2, small tray 8, and main shaft head 9 that can be passed through by silk thread, 4 support bearings 20 are installed on the described door frame 3, and described large tray 2 is placed In the supporting bearing, six guide wheel fixing frames 4 are arranged on the large tray, and three external steel wire guide wheels 1 are installed on the guide wheel fixing frames. The three guide wheel fixing frames are connected to the small tray through connecting plates 15, The small tray 8 is connected to one end of the main shaft head 9, and the other end of the main shaft head is installed on the support frame 13 through a bearing. The small tray guide wheel 14 is arranged on the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com