Ring-beam reinforcing connection structure and ring-beam construction method

A technology for connecting structures and construction methods, which is applied in the direction of building construction and construction, and can solve problems such as low connection strength between steel pipe columns and floor concrete, difficult quality assurance, warping and deformation of ring beams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

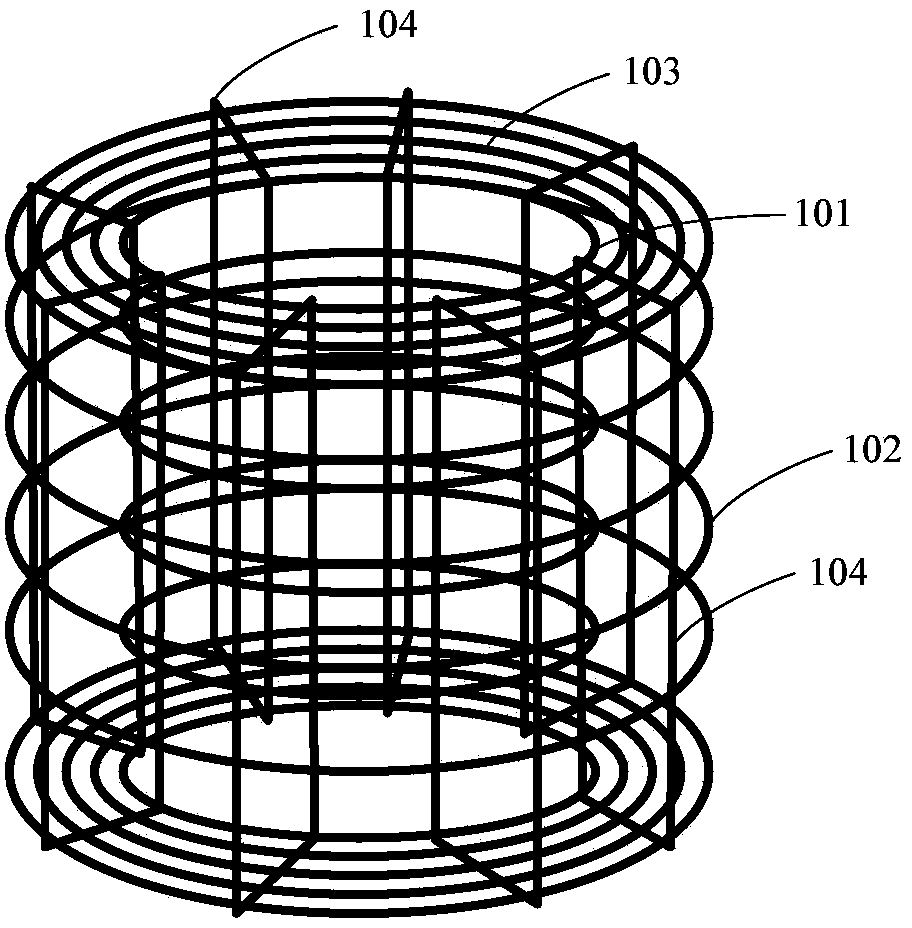

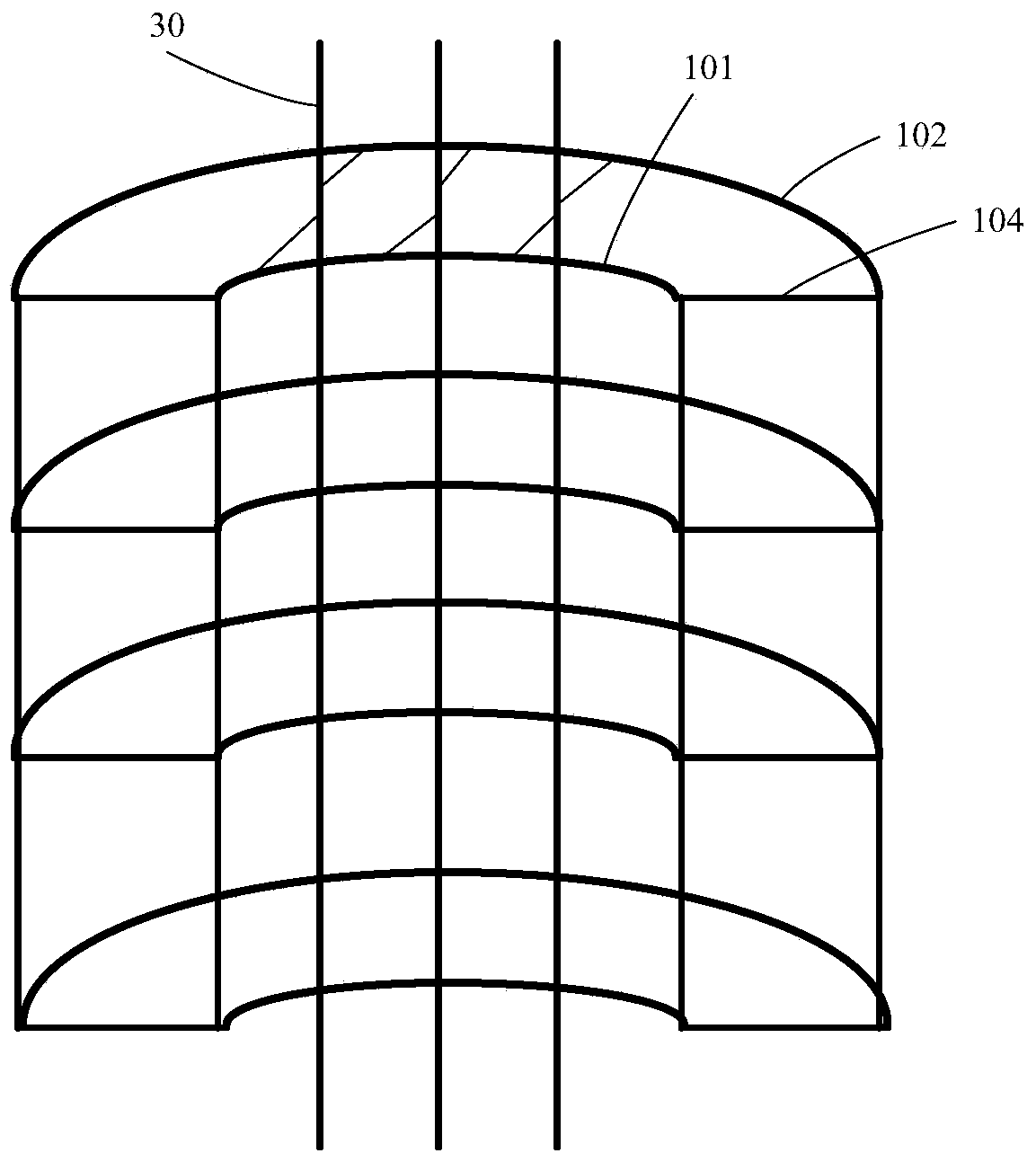

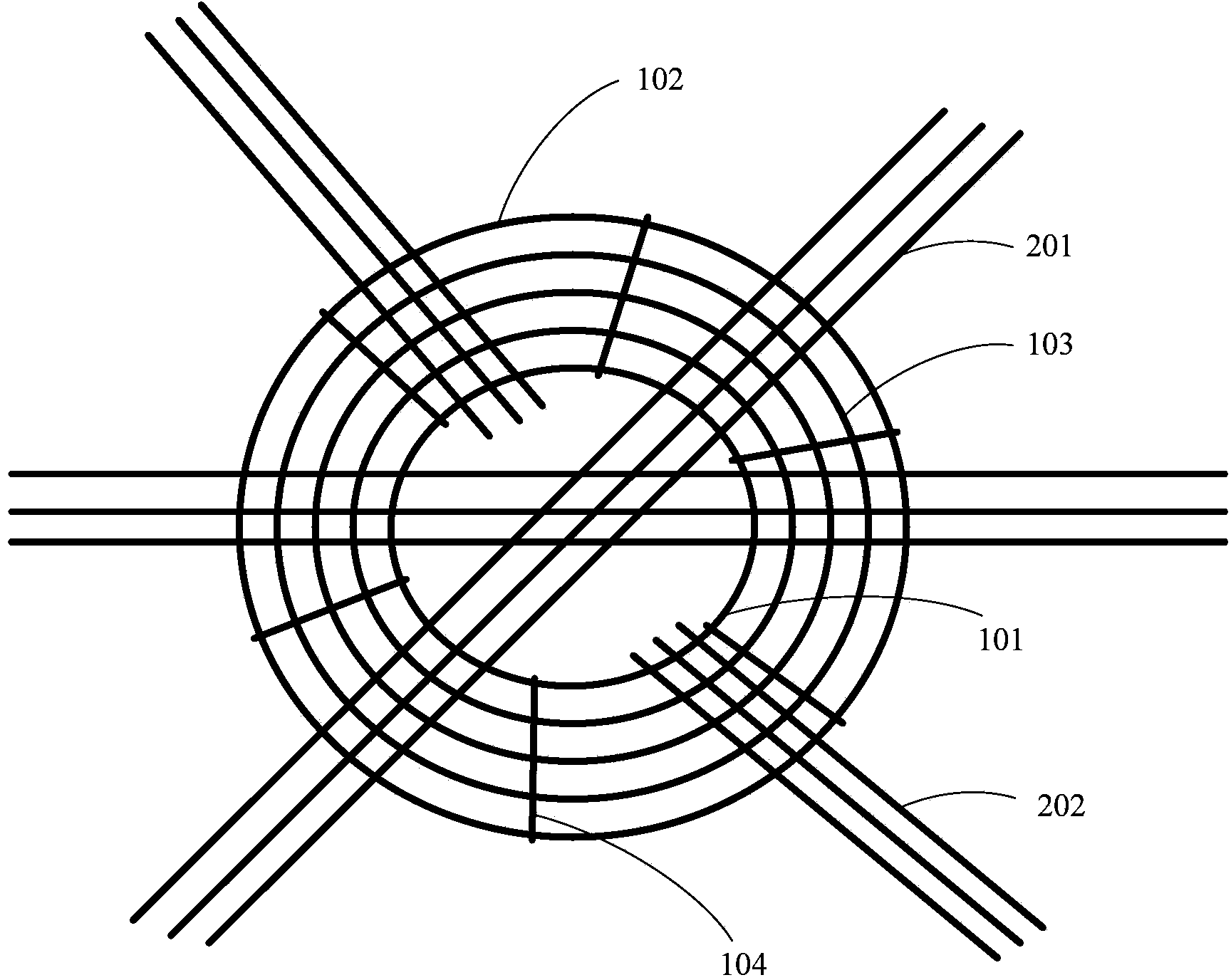

[0029] figure 1 A schematic diagram of the three-dimensional structure of the ring beam reinforcement cage in the ring beam reinforcement connection structure of the present invention is shown. figure 2 A section view showing the ring beam reinforcement cage and beam-column reinforcement connection. image 3 Top view showing ring beam reinforcement cage and floor reinforcement connections. The invention connects the floor steel bar and the beam-column steel bar through the ring beam steel bar cage, so that the floor and the beam and column can be well anchored together, forming a whole at the floor and enhancing the structural strength. The inner ring beam, the outer ring beam and the ring beam are connected by the beam longitudinal bars to form a ring beam reinforcement cage with an integrated structure, which solves the problem of warping an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com