Double-feedback gas flow sensor

A gas flow and sensor technology, applied in liquid/fluid solid measurement, measuring flow/mass flow, applying thermal effect to detect fluid flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to describe the present invention in more detail, the technical solutions and related working principles of the present invention will be described in detail below with reference to the drawings and specific embodiments.

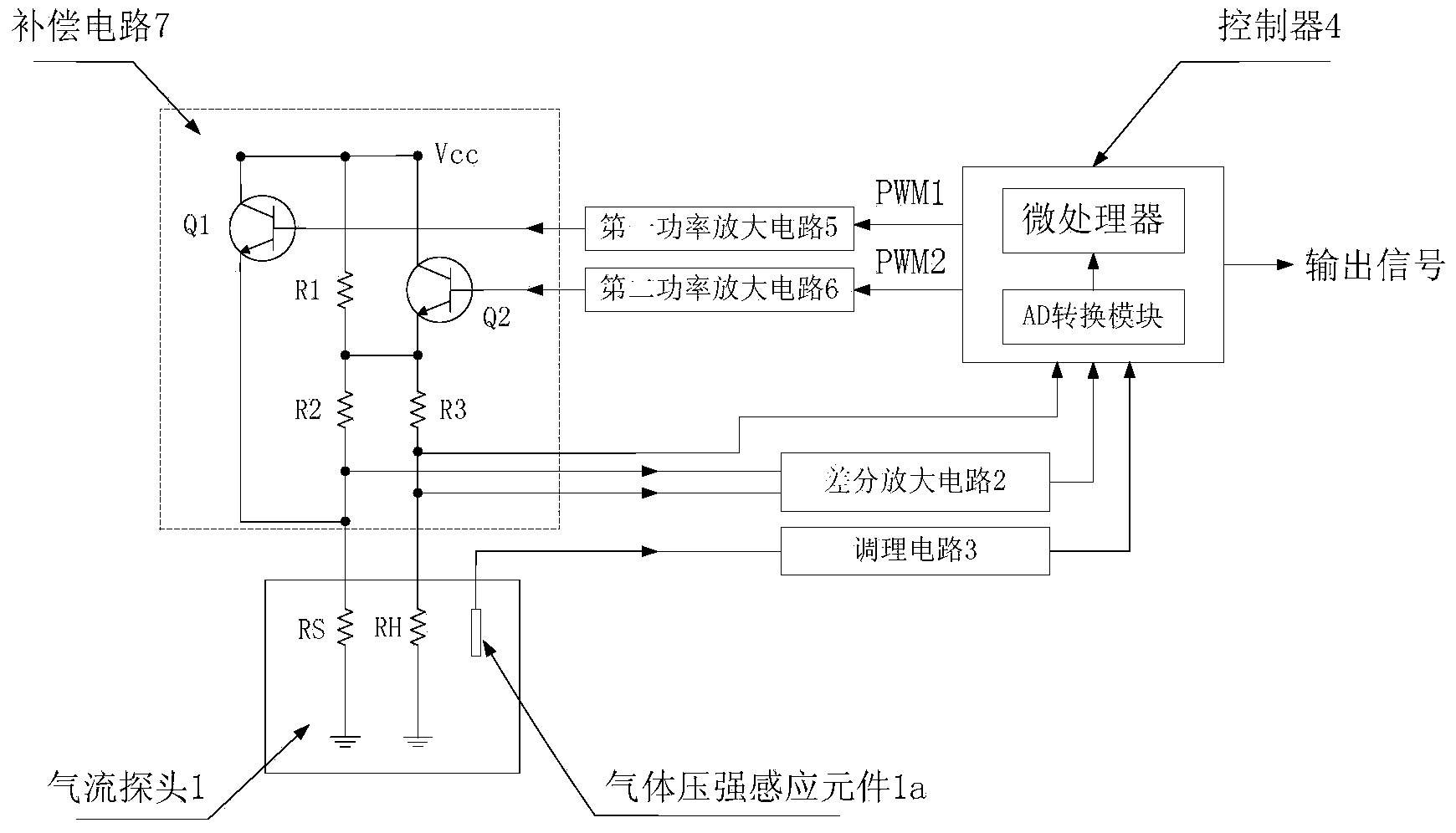

[0045] Such as figure 2 As shown, a dual feedback gas flow sensor includes: a gas flow probe 1, a differential amplifier circuit 2, a conditioning circuit 3, a controller 4, a first power amplifier circuit 5, a second power amplifier circuit 6 and a compensation circuit 7.

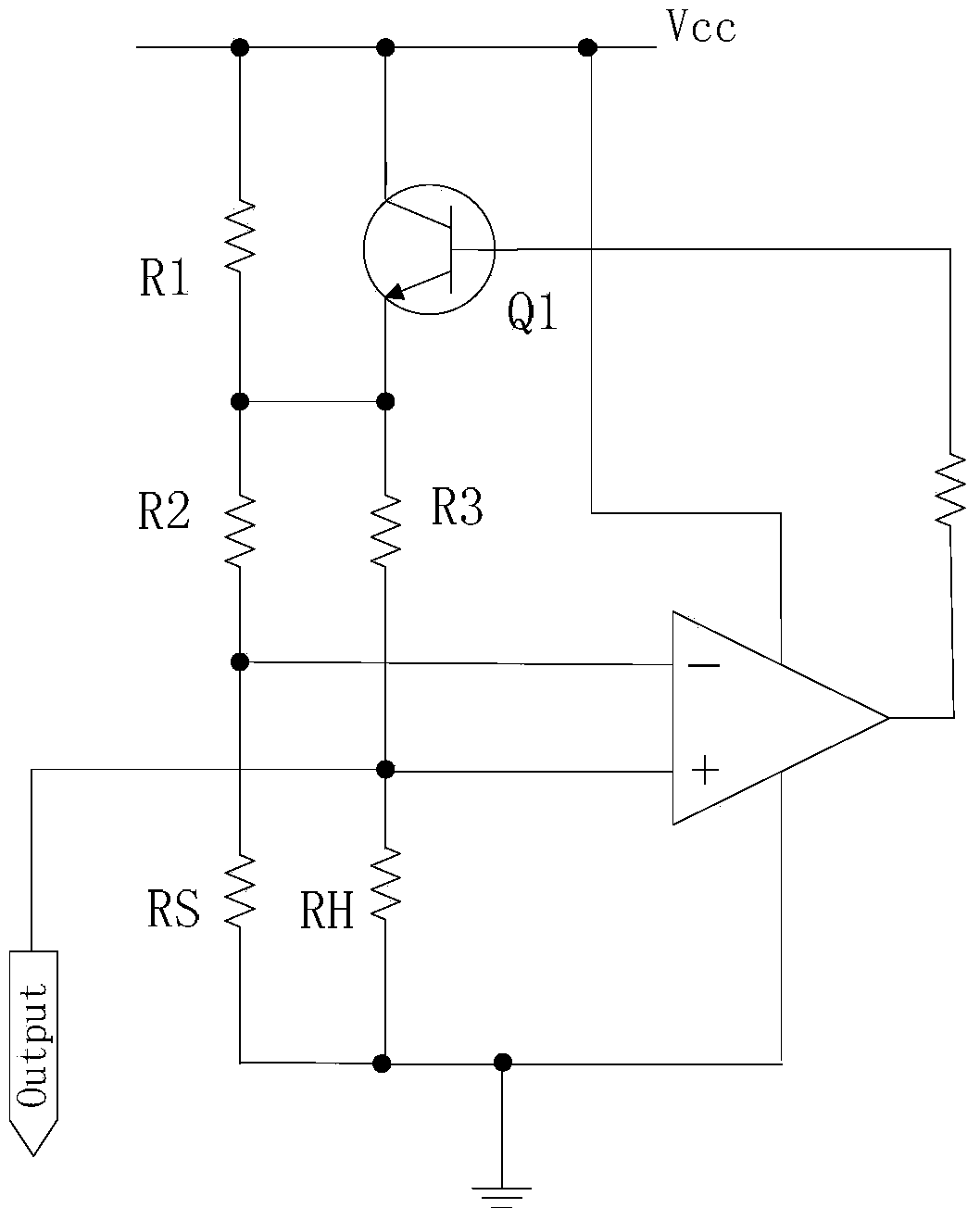

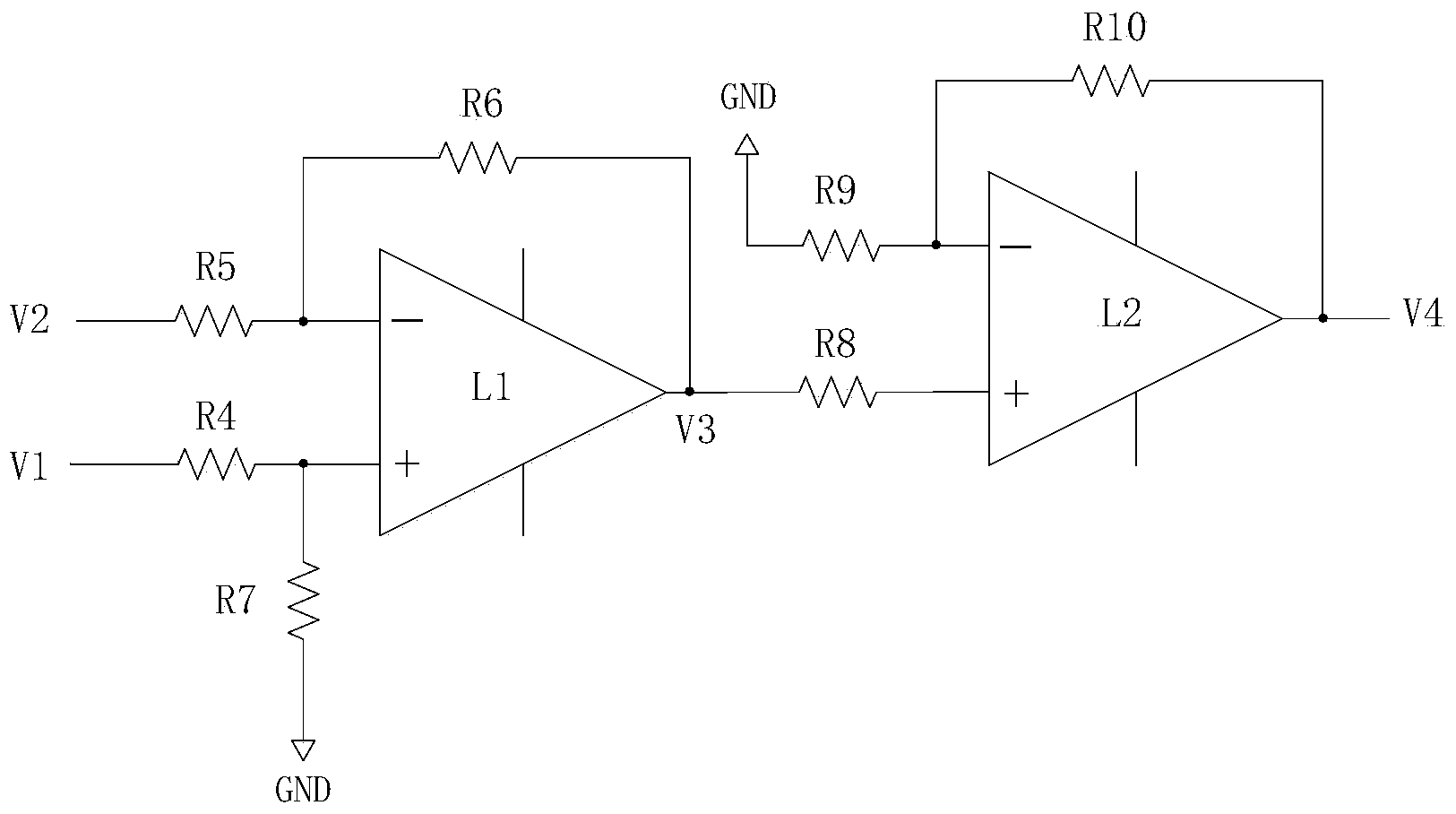

[0046] Airflow probe 1 integrates measuring platinum resistance RH, temperature compensation platinum resistance RS and gas pressure sensing element 1a, which is used to simultaneously detect the flow and pressure of the gas in the pipeline; among them, the voltage of measuring platinum resistance RH and temperature compensation platinum resistance RS is sent to The positive and negative input terminals of the differential amplifier circuit 2 and the output terminal of the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com