Device for dynamically detecting weight loss of coke reaction

A dynamic detection and coke technology, applied in the direction of measuring device, material weighing, weighing by removing certain components, etc., can solve the problem of inability to judge coke well, cannot clearly reflect coke reaction status, blast furnace condition Problems such as abnormality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

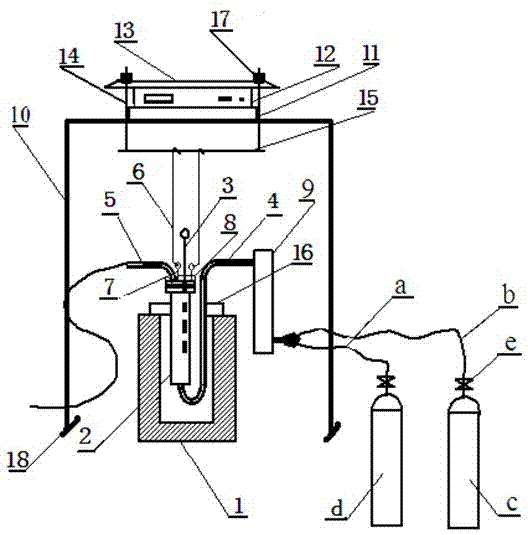

[0020] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0021] A device for dynamically detecting the weight loss of coke reaction, such as figure 1 As shown, it includes a reactor 2 placed in an electric furnace 1 and an electronic scale 12 placed on a support 10. A heat insulating brick 11 is placed under the electronic scale 12, and the heat insulating brick 11 is placed on the support 10. The electronic scale 12 The measuring range is 0-15Kg, and the error is ± 0.2g. In order to ensure the accuracy of the data, the lower end of the bracket 10 is fixedly connected with a shockproof plank 18, and the vibration is buffered by the shockproof plank 18 to prevent the reactor 2 from shaking due to vibration.

[0022] The upper end of the reactor 2 protrudes from the electric furnace 1, so that the reactor 2 remains susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com