Meshing method of finite element model of turbine blade thermal barrier coating

A grid division and thermal barrier coating technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of data extraction and analysis, difficulties in learning and use, and influence on calculation accuracy, etc. , to achieve the effect of data extraction and analysis convenience, avoiding software compatibility problems, and simple and feasible methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

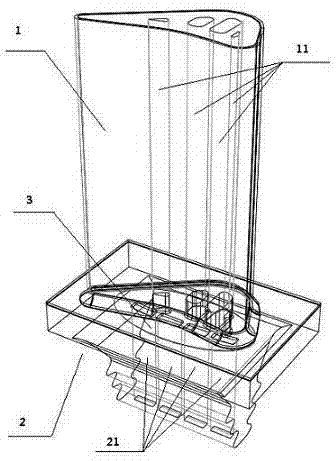

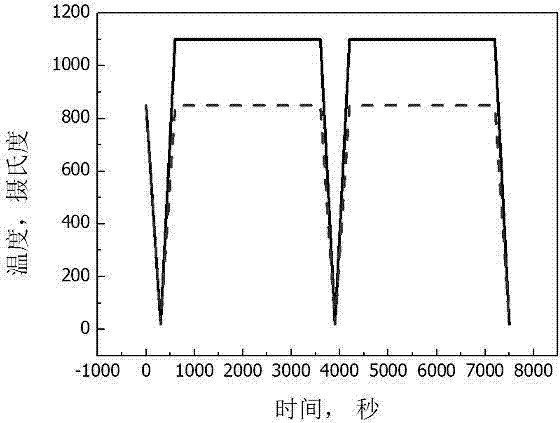

[0051] Select the single turbine blade model that has been established as the implementation object, and use the finite element software ABAQUS to establish the finite element model, mainly to carry out its finite element simulation under thermal cycle load.

[0052] For the sake of convenience and simplification, the present invention makes the following assumptions: 1) The material of each layer of TBCs is isotropic; 2) The thickness of each layer of TBCs is uniform; 3) The ideal elastic-plastic model is adopted; 4) The creep of each layer is a time-hardening model.

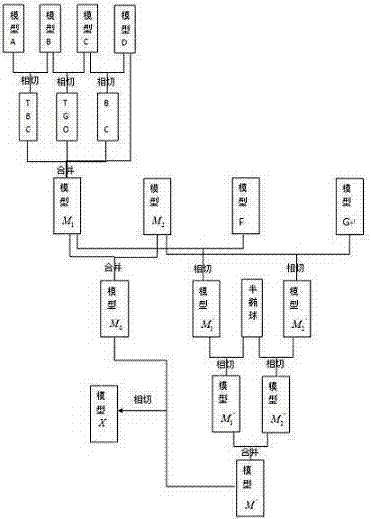

[0053] Firstly, the finite element model of the turbine blade thermal barrier coating is established, and the steps are as follows:

[0054] 1. Construction of geometric model of turbine blade without cooling channel

[0055] (1) Establishment of the geometric model of the blade body

[0056] (1) The establishment of the geometric model in the early stage

[0057] In the geometric model, the thermal barrier ...

Embodiment 2

[0132] In order to simplify, the second embodiment makes the following assumptions: 1) the materials of each layer of coating, base and tenon are uniform and all isotropic; 2) the thickness of each layer of coating is uniform; 3) the tenon is simplified as a cuboid; model, and only the high temperature creep of the TBC layer is considered.

[0133] The finite element model of the thermal barrier coating of the turbine blade is established according to the following steps:

[0134] (1) The establishment of the geometric model in the early stage

[0135] In the model, the ceramic layer is represented by TBC, and the thickness is h c ; The oxide layer is represented by TGO, the thickness is h t ; The transition layer is denoted by BC, and its thickness is h b ; The airfoil base of the turbine blade is denoted by SUB, and the thickness is h s ; The base thickness of the tenon of the turbine blade is h d , where h c =0.40mm, h t = 0.10mm, h b =0.20mm, h s = 1.80 mm, h d =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com