Method for controlling component and thermal treatment technological process of pre-hardening plastic die steel

A plastic mold steel and process technology, applied in the field of steel material manufacturing, can solve problems affecting the surface quality of plastic products, cracking, quenching deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

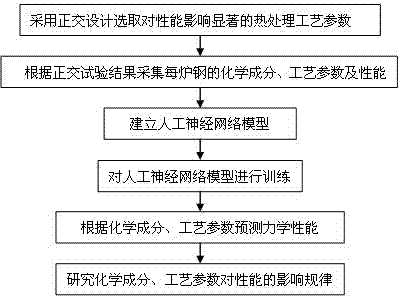

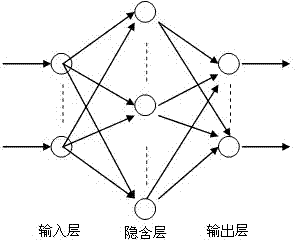

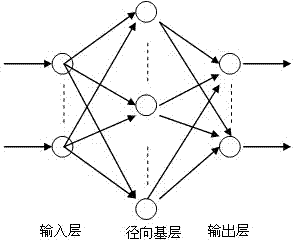

[0080]Embodiment 1: Design an orthogonal test, select the heat treatment process parameters that have a significant impact on performance through the orthogonal test: quenching temperature, cooling method, and tempering temperature, as the input of the artificial neural network (different mold steels that have a significant impact on performance The heat treatment process parameters are different, and the quenching temperature, cooling method and tempering temperature are selected in this embodiment). Table 1 is the input data used for network training; Table 2 is the output data used for network training; Table 3 is the chemical composition of die steel used for network prediction and the heat treatment process parameters used for network prediction; Table 4 is the performance and parameters of network prediction. actual performance. It can be seen from Table 4 that the predicted performance is in good agreement with the actual performance. BP network and GRNN network can be ...

Embodiment 2

[0091] Embodiment 2: Orthogonal experiment is designed, and heat treatment process parameters with significant influence are selected through the orthogonal experiment: quenching temperature and cooling method, first tempering temperature, and second tempering temperature, as the input of the artificial neural network. Table 5 is the input data used for network training; Table 6 is the output data used for network training; Table 7 is the chemical composition of steel used for network prediction and the heat treatment process parameters used for network prediction; Table 8 is the performance and actual performance of network prediction performance. Figure 4 It is the contour map of the hardness of the 1050°C quenched die steel, and other performance indicators of the 1050°C quenched die steel can be drawn as a contour map. It can be seen from Table 8 that the predicted performance is in good agreement with the actual performance. BP network and GRNN network can be used to stu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com