Tire detection hairbrush lubricating mechanism and method thereof

A lubricating mechanism and brush technology, which is applied to tires, other household utensils, household utensils, etc., can solve the problem of impurities in the lubricating fluid, achieve the effects of improving sanitation and cleanliness, smooth operation, and improving detection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

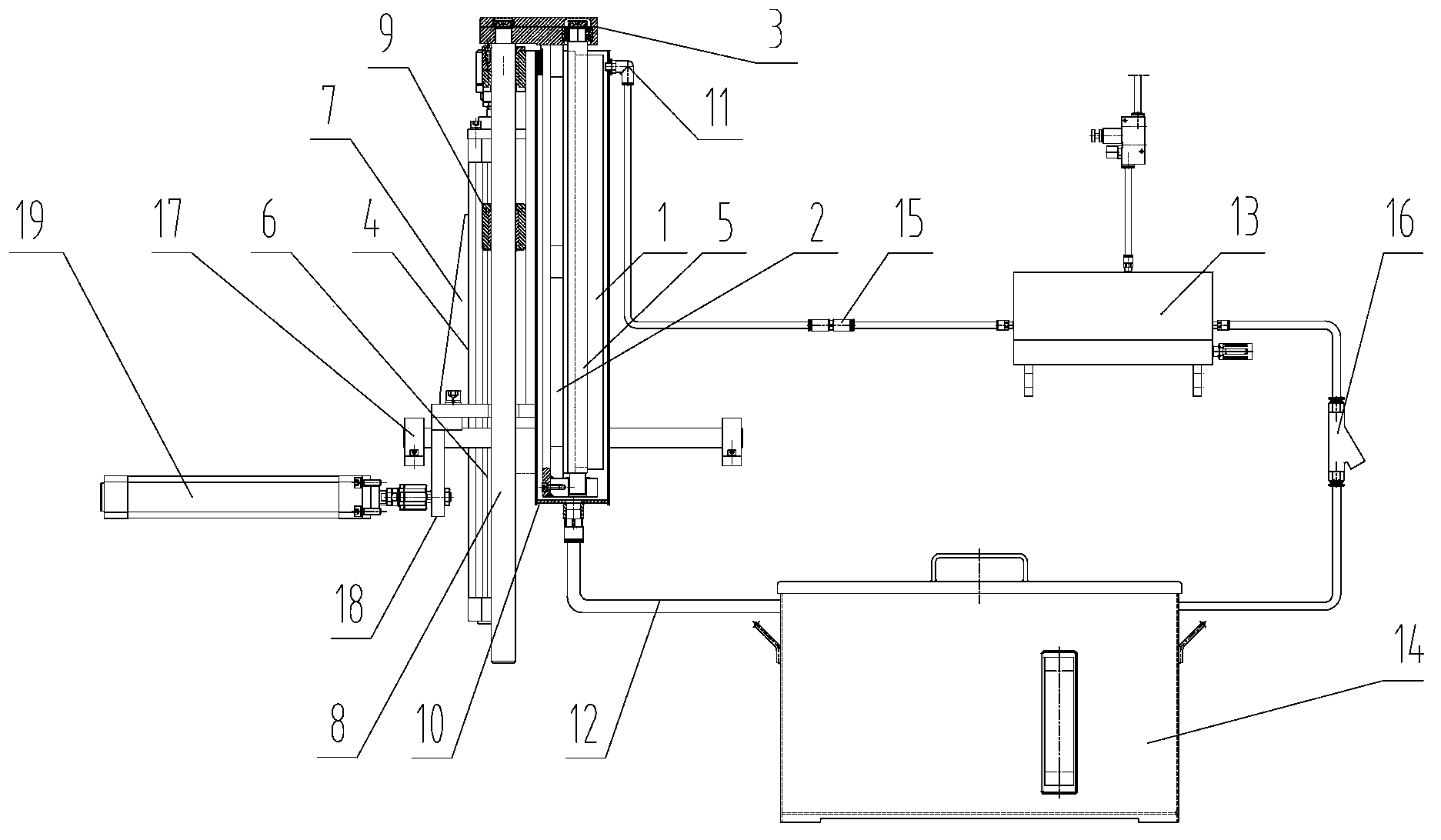

[0053] Example 1, such as figure 1 As shown, the described tire detection brush lubrication mechanism mainly includes:

[0054] Hairbrush 1, is used for smearing lubricating fluid at the spout of detected tire;

[0055] The mounting frame 2 is used to carry the brush 1 and connect the gland 3;

[0056] A pair of rotating rollers 5 are arranged on both sides of the brush 1 and on the mounting frame 2 to assist the rotation of the detected tire;

[0057] The lifting device 4 is used to drive the connecting plate 3 to drive the brush 1 to vertically reciprocate up and down and be positioned at the mouth of the detected tire; the lifting device 4 includes a lifting cylinder 6, and the driving shaft of the lifting cylinder 6 is upward Supporting the connecting plate 3, the connecting plate 3 is also connected with a vertical guide mechanism;

[0058]The vertical guide mechanism includes a guide rod 8 connected to the connecting plate 3, and a guide rod installed on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com