Method for assembling nanoparticle carrying laminin and sdf-1α on the surface of ti material

A technology of laminin and SDF-1, which is applied in the direction of surface coating liquid devices, special surfaces, coatings, etc., can solve the problems of limited application, insufficient blood compatibility, etc., and achieves wide application range and excellent preparation process And the fixation method is simple and easy to operate, and the effect of inhibiting thrombus formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

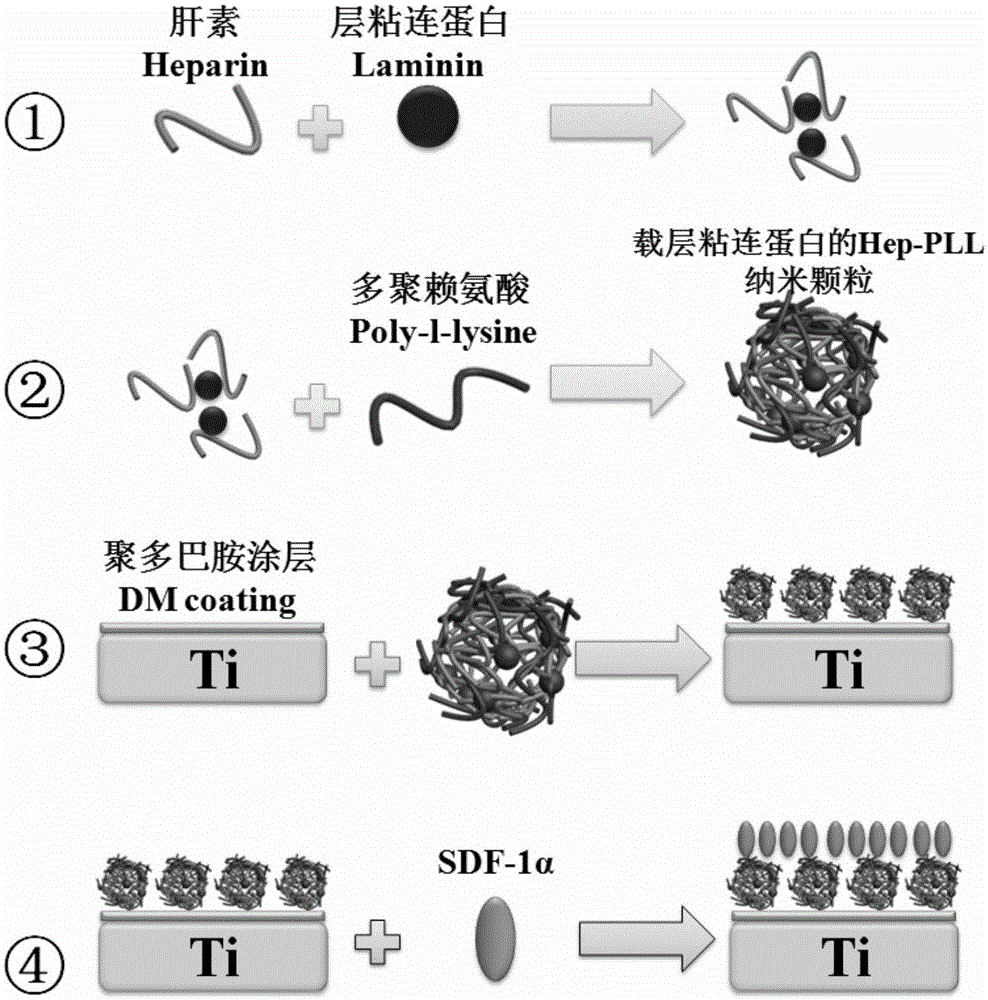

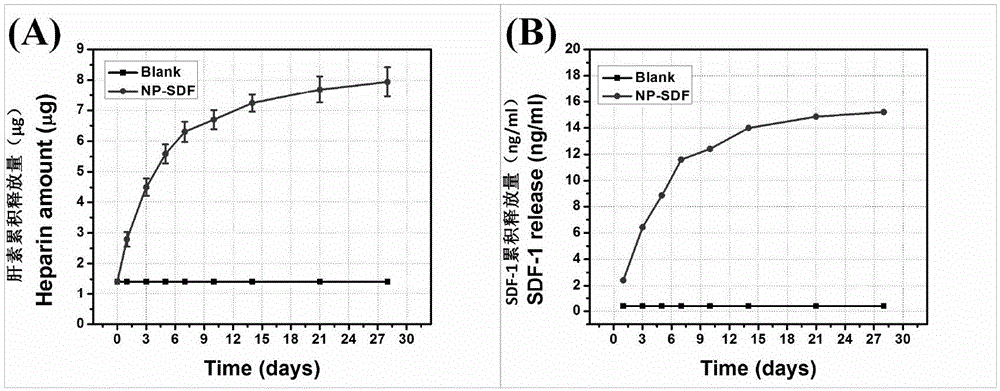

[0026] see figure 1 , the first embodiment of the present invention is a method for loading laminin nanoparticles and SDF-1α on the surface of a Ti material, the steps of which are:

[0027] A, polydopamine is deposited on the surface of cardiovascular metal Ti material to deposit polydopamine coating, and dry at 37°C;

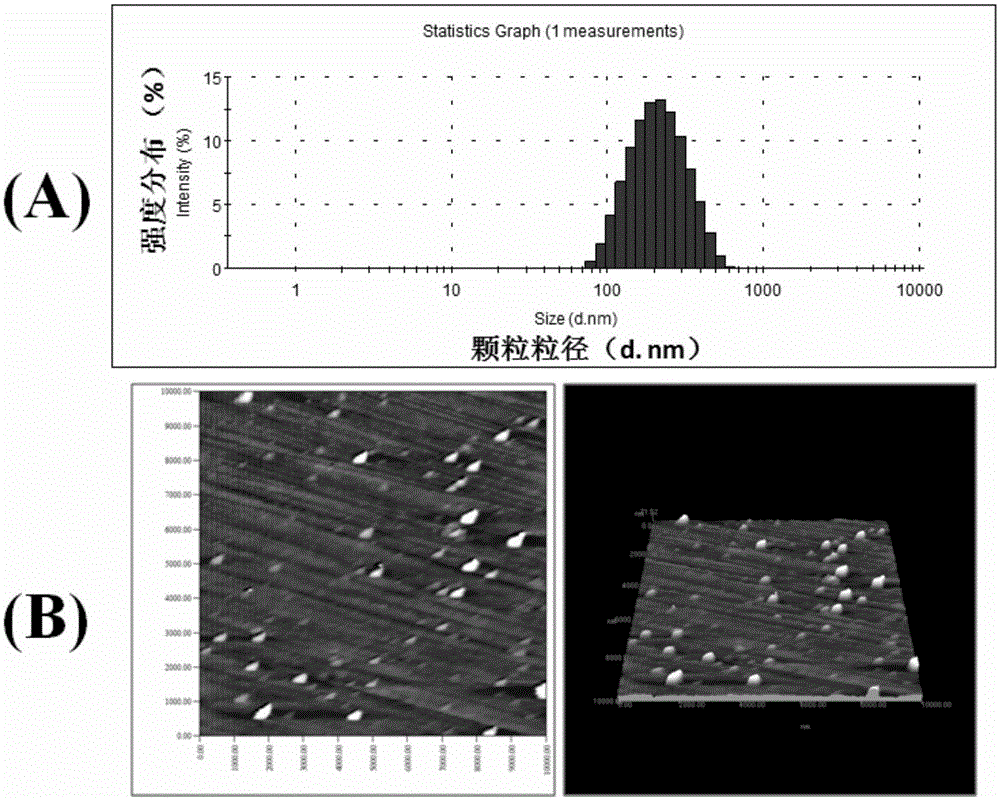

[0028] B. Preparation of laminin-loaded nanoparticles Add an equal volume of laminin solution with a concentration of 30 μg / ml to a heparin sodium solution with a concentration of 10 mg / ml, and let stand at 37°C for 1 hour; Under stirring conditions, add an equal volume of heparin sodium and laminin mixture dropwise to a polylysine (PLL, MW150-300KDa) solution with a concentration of 0.3mg / ml;

[0029] C. Nanoparticle immobilization Soak the sample deposited with polydopamine in step A in the nanoparticle suspension obtained in step B, react under shaking conditions at 50°C for 24 hours, and wash with phosphate buffered saline (PBS) and double distilled water...

Embodiment 2

[0032] A method for loading laminin-loaded nanoparticles and SDF-1α on the surface of a Ti material, the steps of which are:

[0033] A, polydopamine is deposited on the surface of the metal Ti material to deposit a polydopamine coating, and dry at 37 ° C;

[0034] B. Preparation of laminin-loaded nanoparticles Add an equal volume of laminin solution with a concentration of 300 μg / ml to a heparin sodium solution with a concentration of 30 mg / ml, and let stand at 37°C for 3 hours; Under stirring conditions, add an equal volume of heparin sodium and laminin mixture dropwise to a polylysine (PLL, MW150-300KDa) solution with a concentration of 1.0mg / ml;

[0035] C. Nanoparticle immobilization Soak the sample deposited with polydopamine in step A in the nanoparticle suspension obtained in step B, react under shaking conditions at 15°C for 6 hours, and wash with phosphate buffered saline (PBS) and double distilled water respectively Rinse and save for later use;

[0036] D. Assemb...

Embodiment 3

[0038] A method for loading laminin-loaded nanoparticles and SDF-1α on the surface of a Ti material, the steps of which are:

[0039] A, polydopamine is deposited on the surface of the metal Ti material to deposit a polydopamine coating, and dry at 37 ° C;

[0040] B. Preparation of laminin-loaded nanoparticles Add an equal volume of laminin solution with a concentration of 200 μg / ml to a heparin sodium solution with a concentration of 20 mg / ml, and let stand at 37°C for 2 hours; Under stirring conditions, add an equal volume of heparin sodium and laminin mixture dropwise to a polylysine (PLL, MW150-300KDa) solution with a concentration of 0.5mg / ml;

[0041] C. Nanoparticle immobilization Soak the sample deposited with polydopamine in step A in the nanoparticle suspension obtained in step B, react under shaking conditions at 37°C for 12 hours, and wash with phosphate buffered saline (PBS) and double distilled water respectively Rinse and save for later use;

[0042] D. Assembl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com