Processing method of sealing teeth on the sealing surface of a certain type of high pressure turbine outer ring

A technology of high-pressure turbine and sealing teeth, which is applied in the field of mechanical processing, can solve the problems of air film hole 2 orifice flanging, workpiece scrapping, air film hole 2 not smooth, etc., to achieve the effect of improving efficiency and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

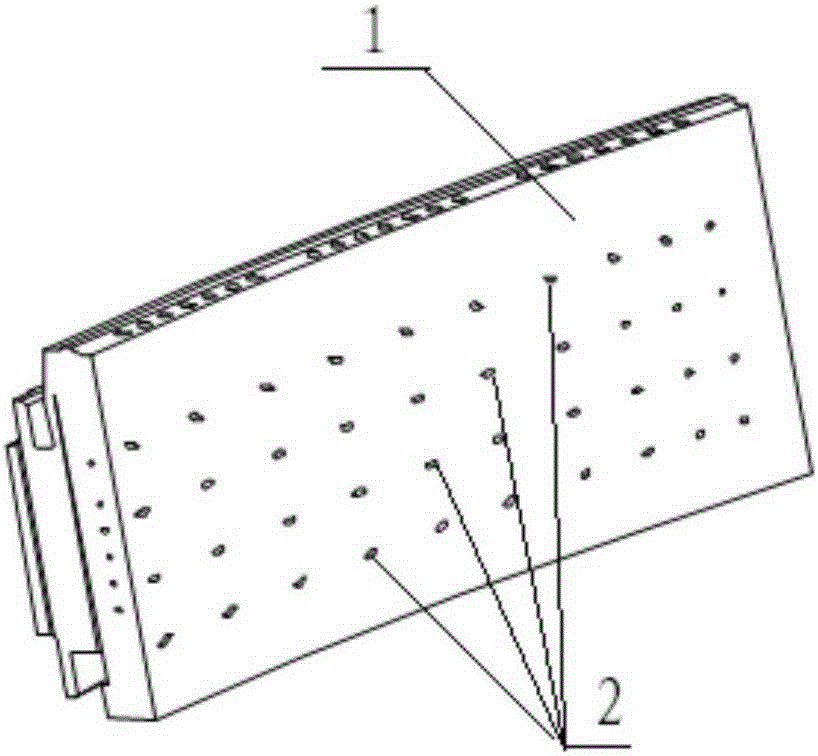

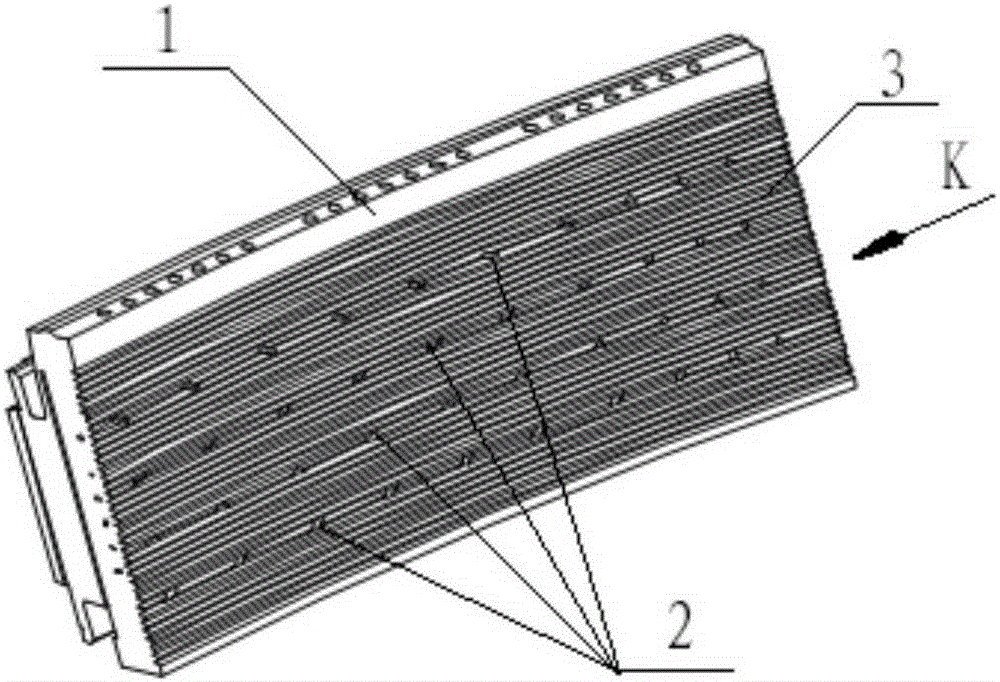

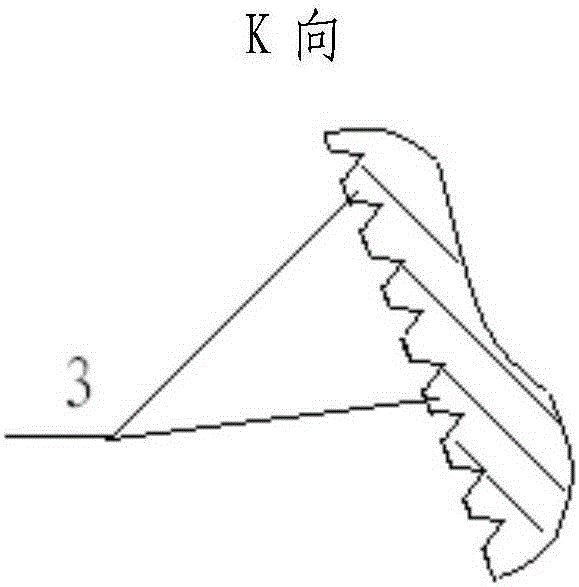

[0025] A processing method for sealing teeth on the sealing surface of a certain type of high-pressure turbine outer ring. The outer ring of this type of high-pressure turbine is composed of 27 outer ring arc segments 1 with the same structure combined along the circumference, and each outer ring arc segment 1 is a hollow structure. , on the sealing surface of the outer ring arc section 1, there are 5 rows of air film holes 2 evenly distributed in the radial direction, each row has 12 air film holes, the diameter of the air film holes is 0.55mm, and on the outer ring arc section 1 37 sealing teeth 3 uniformly distributed in the radial direction need to be processed on the sealing surface of the outer ring, and the sealing teeth 3 penetrate the sealing surface of the outer ring arc segment 1 along the arc direction; 2 has been processed, and the sealing surface of the outer ring arc section 1 is ground into a cylindrical surface; it is characterized in that the steps of processi...

Embodiment 2

[0034] A processing method for sealing teeth on the sealing surface of a certain type of high-pressure turbine outer ring. The outer ring of this type of high-pressure turbine is composed of 42 outer ring arc segments 1 with the same structure combined along the circumference, and each outer ring arc segment 1 is a hollow structure. , on the sealing surface of the outer ring arc section 1, there are 4 rows of air film holes 2 evenly distributed in the radial direction, each row has 8 air film holes, the diameter of the air film holes is 0.6mm, and on the outer ring arc section 1 37 sealing teeth 3 uniformly distributed in the radial direction need to be processed on the sealing surface of the outer ring, and the sealing teeth 3 penetrate the sealing surface of the outer ring arc segment 1 along the arc direction; 2 has been processed, and the sealing surface of the outer ring arc section 1 is ground into a cylindrical surface; it is characterized in that the steps of processing...

Embodiment 3

[0043]A processing method for sealing teeth on the sealing surface of a certain type of high-pressure turbine outer ring. The outer ring of this type of high-pressure turbine is composed of 27 outer ring arc segments 1 with the same structure combined along the circumference, and each outer ring arc segment 1 is a hollow structure. , on the sealing surface of the outer ring arc section 1, there are 4 rows of air film holes 2 evenly distributed in the radial direction, each row has 10 air film holes, and the diameter of the air film holes is 0.8mm. 37 sealing teeth 3 that are evenly distributed in the radial direction need to be processed on the sealing surface of the outer ring. The sealing teeth 3 penetrate the sealing surface of the outer ring arc segment 1 along the arc direction; 2 has been processed, and the sealing surface of the outer ring arc section 1 is ground into a cylindrical surface; it is characterized in that the steps of processing the sealing teeth 3 are as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com