Hydraulic Tubing Descaler

A hydraulic and descaler technology, which is applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of limited impact force of the well gauge, impossibility to pass through, and narrowing of the inner diameter of the pipe, so as to achieve operation and use Convenient, easy to solve, good descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

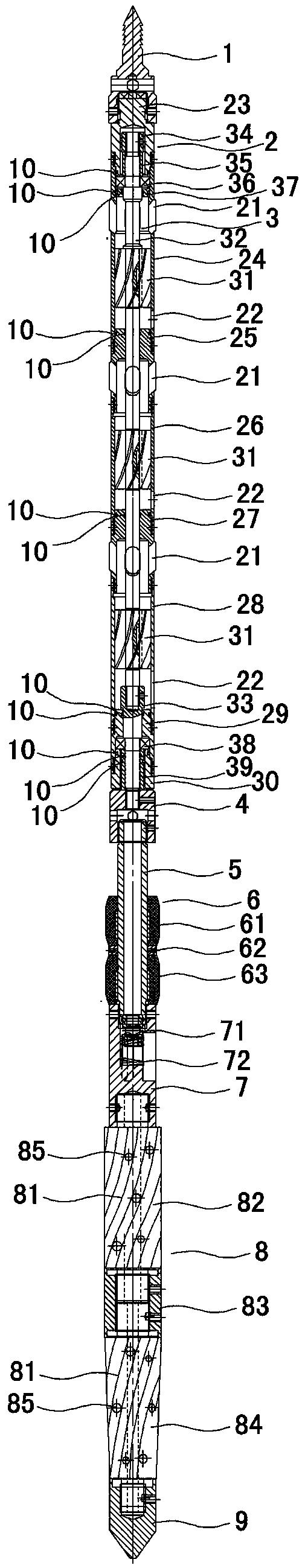

[0007] Such as figure 1 As shown, it includes a fishing head 1, a main body 2, a core rod 3, a joint 4, a rubber cartridge core 5, a rubber cartridge assembly 6, a connecting body 7, a descaling body 8 and a guide head 9, and the lower end of the fishing head 1 is threaded It is axially connected with the upper end of the main body 2, and the core rod 3 is installed in the main body 2 and axially connected with the main body 2. The upper end of the rubber cartridge core 5 is axially connected through threads, the stripping assembly 6 is set on the rubber cartridge core 5, the lower end of the rubber cartridge core 5 is axially connected with the upper end of the connecting body 7 through threads, and the upper end of the descaling body 8 The lower end of the connecting body 7 is axially connected through threads, and the lower end is axially connected with the upper end of the guide head 9 through threads. The central hole and the radial hole of the body 7 communicate with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com