A special cutting tool for helical milling holes of laminated materials

A technology of helical hole milling and lamination of materials, applied in milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problem of optimal design without cutting edge layout, reduce delamination and burrs, suppress vibration, and improve hole exit quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

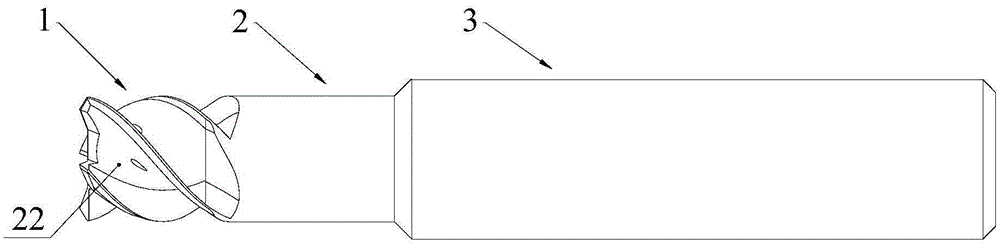

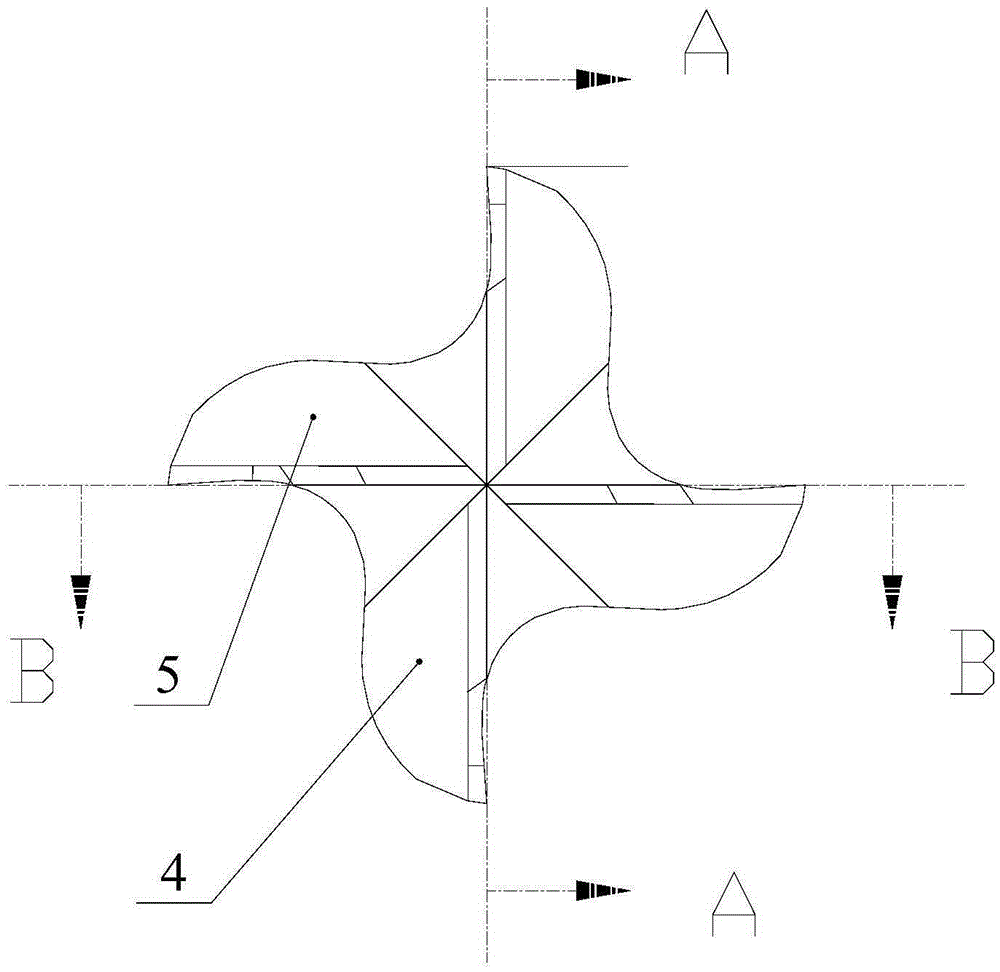

[0031] Such as Figure 1~2 As shown, a special cutting tool for helical milling of laminated materials includes a cutting head 1, a neck 2 and a tool bar 3 connected in sequence. The axially symmetrical cutter teeth of the cutter bar are the first cutter teeth 4, the other pair of cutter teeth are the second cutter teeth 5, and the neck side wall is provided with four side edges connected with the corresponding cutter teeth.

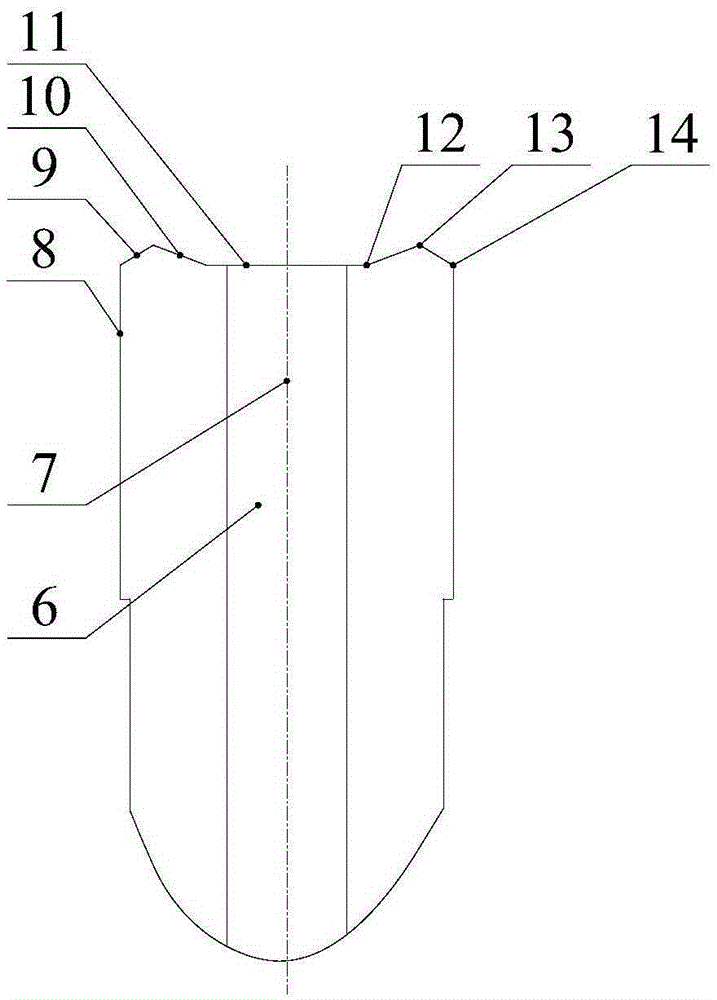

[0032] Such as image 3 As shown, the first cutter tooth 4 includes a first inner cutting edge 11, a first middle cutting edge 10, and a first outer cutting edge 9 connected in sequence, the first inner cutting edge is perpendicular to the axis 7 of the cutter bar, and The cutting edge intersects at the first cutting edge inflection point 12, the first middle cutting edge intersects the first outer cutting edge at the first middle tool point 13, and the first outer cutting edge intersects the corresponding first side edge 8 at the first outer The tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com