Negative rake milling cutter for milling carbon fiber enhanced silicon carbide ceramic matrix (C/Si) composite materials

A technology of milling and composite materials, applied in the direction of tools, milling cutters, metal processing equipment, etc. for milling machines, it can solve the problems of poor processing quality, tool wear, delamination and tearing, and reduce burrs and delamination. phenomenon, anti-breakage tool life, the effect of excellent cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

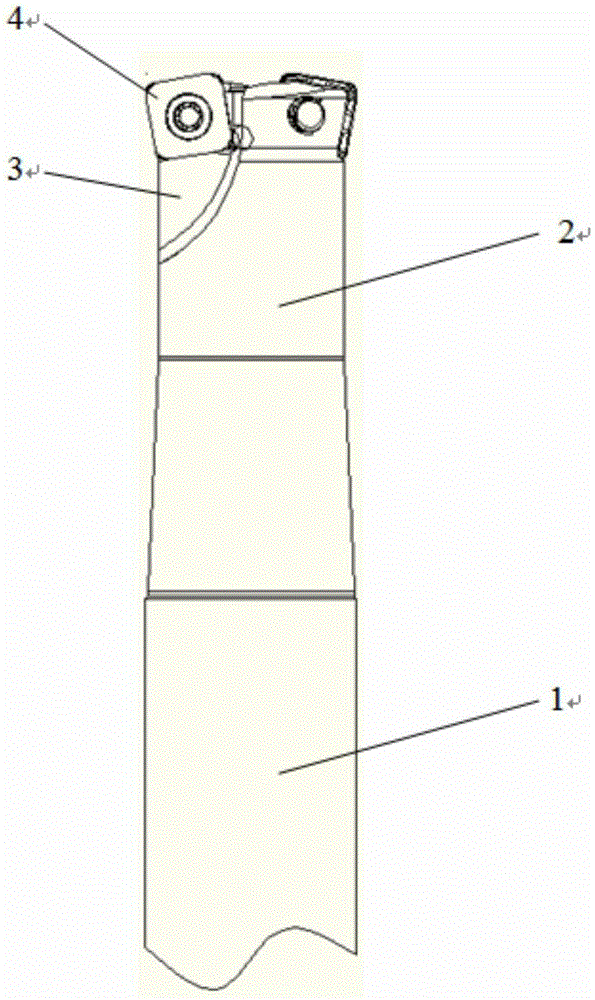

[0018] Such as figure 1 As shown, an end mill for milling of C / SiC composite materials is composed of: a tool handle 1, the tool handle is used for installing a knife neck 2 of a blade, and the knife neck has two blades The installation groove 3, the blade 4 is installed in the blade installation groove. The tool handle is used to connect the spindle of the machine tool, and the blade is mounted on the tool handle with screws, on which PCD is welded for cutting.

[0019] The edge shape of the end mill is a negative rake angle, the number of teeth of the milling cutter is 1-2, and the helix angle is 30°.

Embodiment 2

[0021] The invention is used for high-efficiency milling of C / SiC composite materials. Before processing, install the blade on the handle with screws to ensure good contact between the PCD blade and the mounting groove. After assembly, it should be ensured that the radial runout tolerance of the top of the PCD insert cutting edge is within 0.03mm, and the end face circular runout tolerance of the side is within 0.02mm.

[0022] During the use of the present invention, when the cutting edges of individual PCD blades are blunted or chipped, a screwdriver can be used to remove the worn PCD blades and replace them with new PCD blades. When the accuracy requirements are not too high, the wear or edge chipping of individual inserts does not need to be replaced when the cutting performance has little effect. When the PCD blade wears a lot and needs to be replaced, the PCD blades can be replaced and adjusted one by one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com