A drilling method for high-hardness fiber-reinforced ceramic matrix composite parts

A fiber-reinforced and composite material technology, applied in drilling/drilling equipment, tools for lathes, workpieces, etc., can solve the problems of harsh cooling conditions, poor thermal conductivity, tearing, etc., and improve drilling efficiency and machining surface quality, improving cutting performance and service life, and improving cutting performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

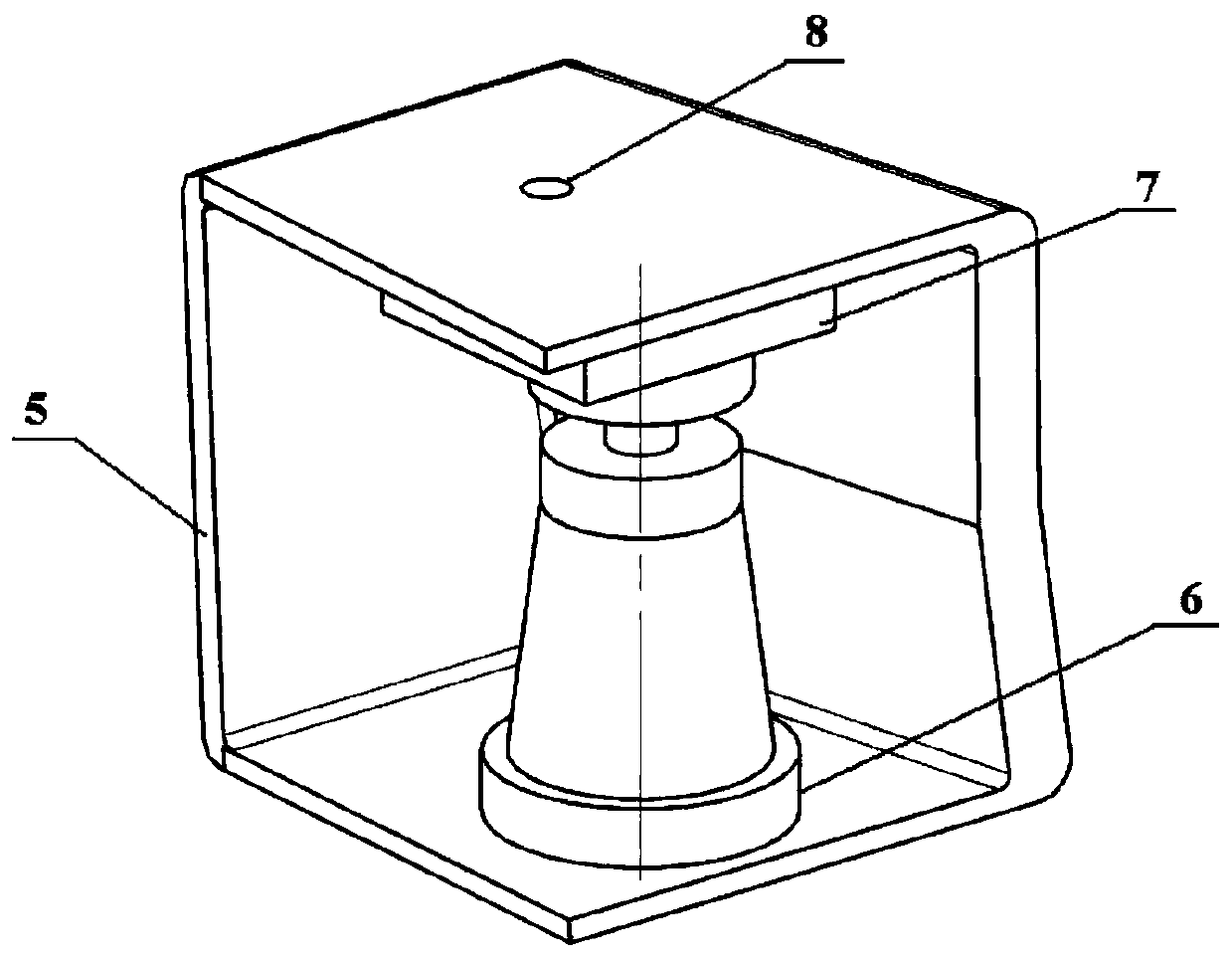

[0039] Such as figure 1 , figure 2 and image 3 As shown, the drilling process of the variable-wall thickness thin-walled box-shaped parts of high-hardness fiber-reinforced ceramic matrix composites includes the following steps:

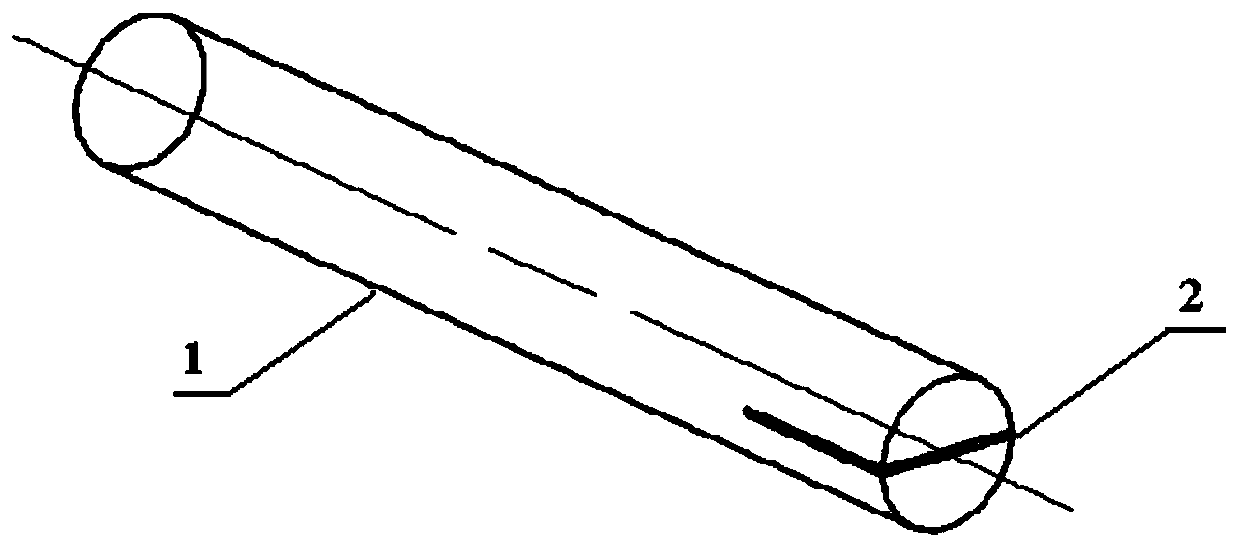

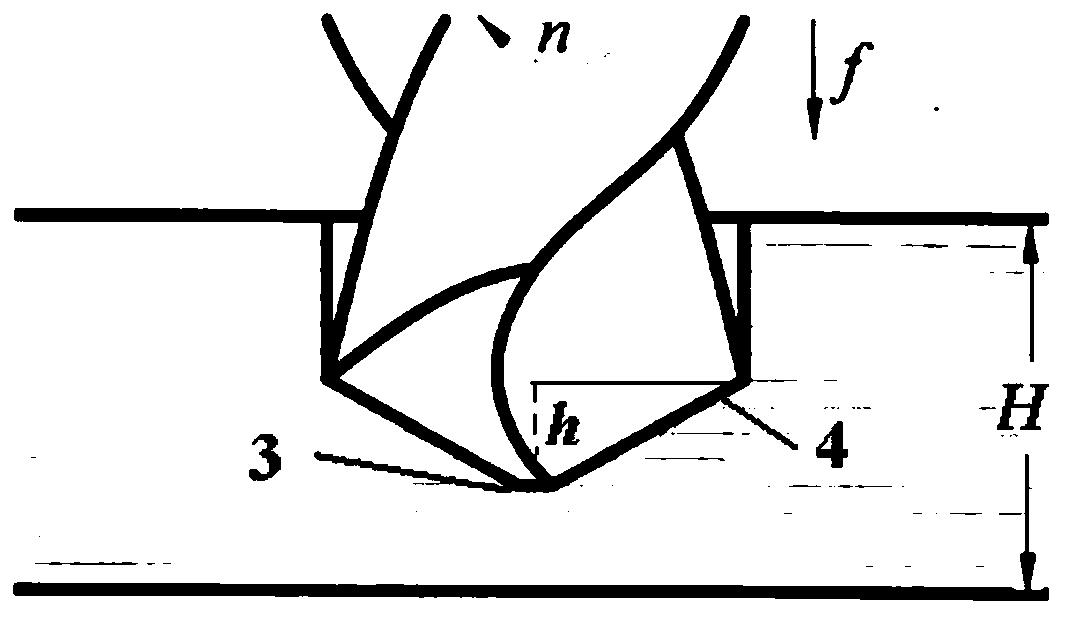

[0040] (1) Design and manufacture integral sintered PCD drills suitable for drilling high hardness fiber reinforced ceramic matrix composites, such as figure 1As shown, among them, the integral sintered PCD drill is to open a 0.3mm wide transverse groove 2 on the solid carbide drill blank 1, inject the diamond powder into the groove after mixing with the binder, and sinter it under high temperature and high pressure to develop and shape it. Get the PCD drill bit blank with "sandwich" structure, and then grind the drill tip into the required geometric shape according to the material matching. Take the geometric parameters of integral sintered PCD drill bit with a diameter of Φ8.5mm as an example: the top angle of the drill bit is 120°, the helix a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com