An end effector for helical milling holes

An end effector and helical hole milling technology, which is applied to the driving device, milling machine equipment, details of milling machine equipment, etc., can solve the problems of eccentricity error and eccentricity cannot be adjusted automatically, so as to reduce heat accumulation, improve surface processing quality, The effect of improving tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

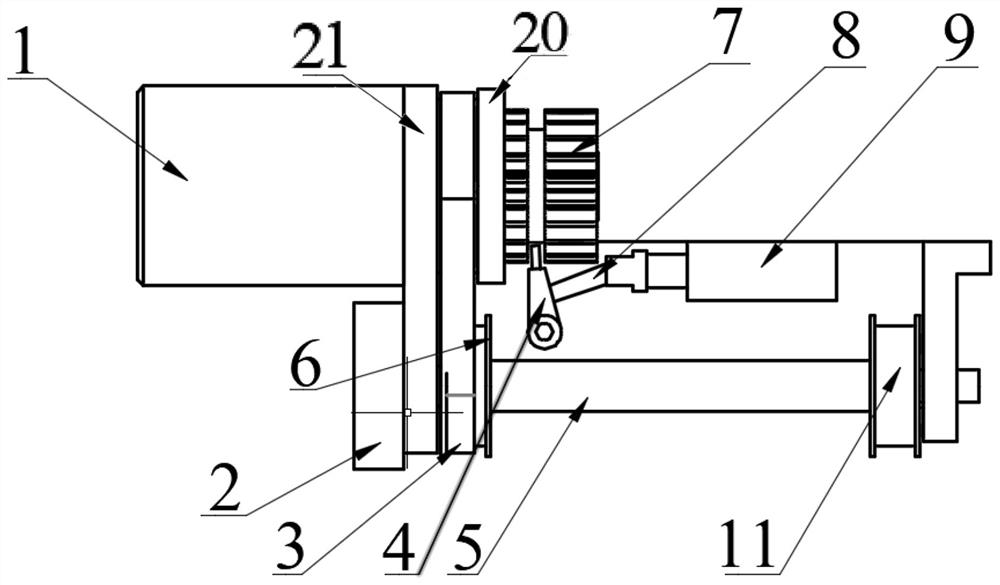

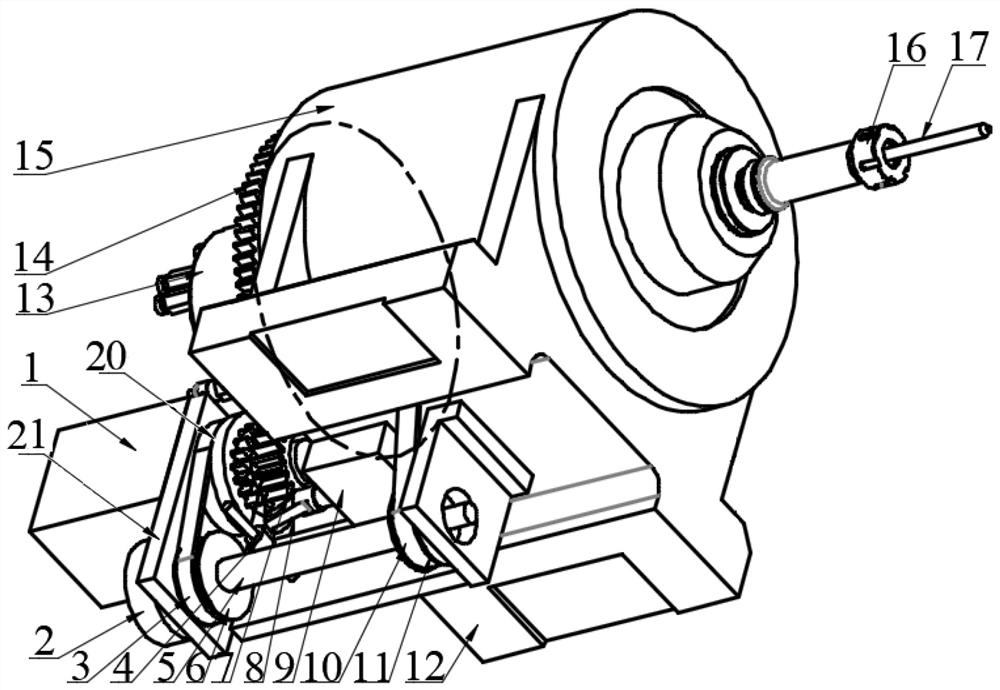

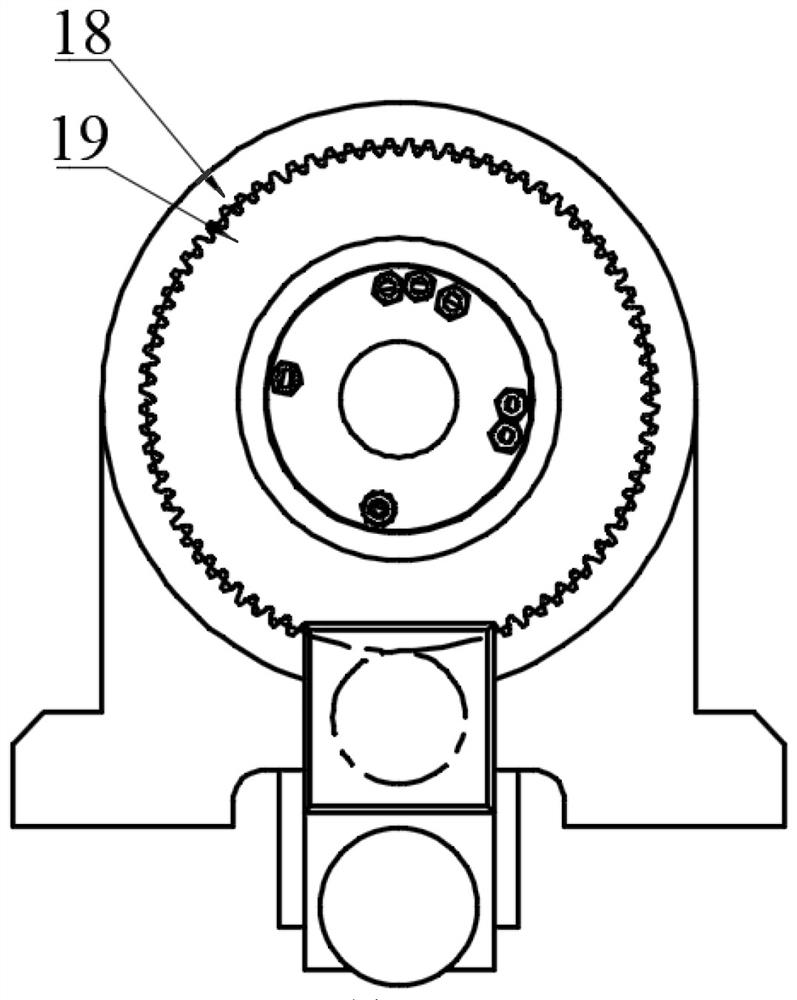

[0042] In this embodiment, the workpiece aircraft skin material to be processed is made of 2024 aluminum alloy. Dimensions: diameter 120mm, width 100mm, thickness 2mm. The diameter of the milling cutter is 4mm, the rotation speed of the milling cutter is 3000r / min, the feed rate is 24mm / min, the diameter of the hole is φ5mm, and the eccentricity (the vector sum of e1 and e2) is 0.5mm.

[0043] Conclusion: All the hole making is completed, and the operation is convenient and easy to operate. The hole-making accuracy of each hole can reach H8. It greatly reduces the work intensity of workers and improves work efficiency.

Embodiment 2

[0045] In this embodiment, the workpiece aircraft to be processed is usually made of difficult-to-machine materials, and the material is carbon fiber composite material (CFRP). Dimensions: diameter 120mm, width 100mm, thickness 2mm. The diameter of the milling cutter is φ6mm, the rotational speed of the milling cutter is 6000r / min, the feed rate is 48mm / min, the diameter of the hole is φ8mm, and the eccentricity (the vector sum of e1 and e2) is 1mm.

[0046] Conclusion: All the hole making is completed, and the operation is convenient and easy to operate. The hole-making accuracy of each hole can reach H8. It greatly reduces the work intensity of workers and improves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com