Engine hood installation tool and using method thereof

A technology for engine compartment cover and installation tooling, which is applied to auxiliary devices, manufacturing tools, metal processing equipment, etc., and can solve the problem of excessive flatness of the gap between the engine compartment cover and the fender, difficulty in judging the qualified condition of the gap flatness, magnets Not easy to absorb and other problems, achieve the effect of light weight, simple structure, and reduce matching problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

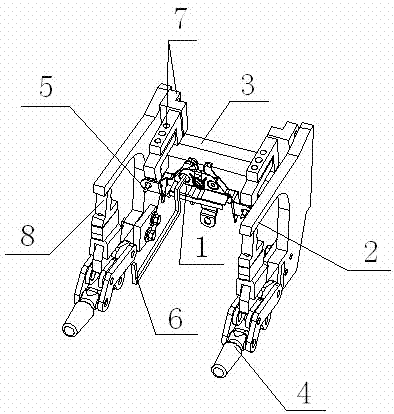

[0022] Such as figure 1 As shown, the bonnet installation tooling of this embodiment includes a body composed of two plates 9 arranged in parallel and a reinforcing beam 3 connecting the plates 9, a profiling lock mechanism 1 is installed between the two plates 9, each The same side of the plate 9 is equipped with a protruding reference block 2 of predetermined thickness and a positioning pin 5 that can be inserted into the positioning hole of the front beam of the body-in-white; The locking mechanism 4 that the front beam of the assembly is fixed.

[0023] The locking mechanism 4 is a manual clamp, and the free end of the manual clamp is equipped with a height-adjustable compression block 8. By adjusting the height of the compression block 8, the clamping force of the manual clamp can be adjusted. In order to adapt to different structures, the front beam of the engine compartment assembly of the body-in-white. The above is the standard part mechanism, you can choose Taiwan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com