Plasma subcritical/supercritical fluid generator and abrasive water jet cutting head comprising generator

A supercritical fluid and plasma sub-technology, which is applied in the direction of non-mechanical generation of abrasive jets, abrasives, explosion generating devices, etc., can solve the problems of low thermal efficiency, large volume, unsuitable for small-scale system integration, etc., to achieve High thermal efficiency and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in more detail below in conjunction with accompanying drawing example:

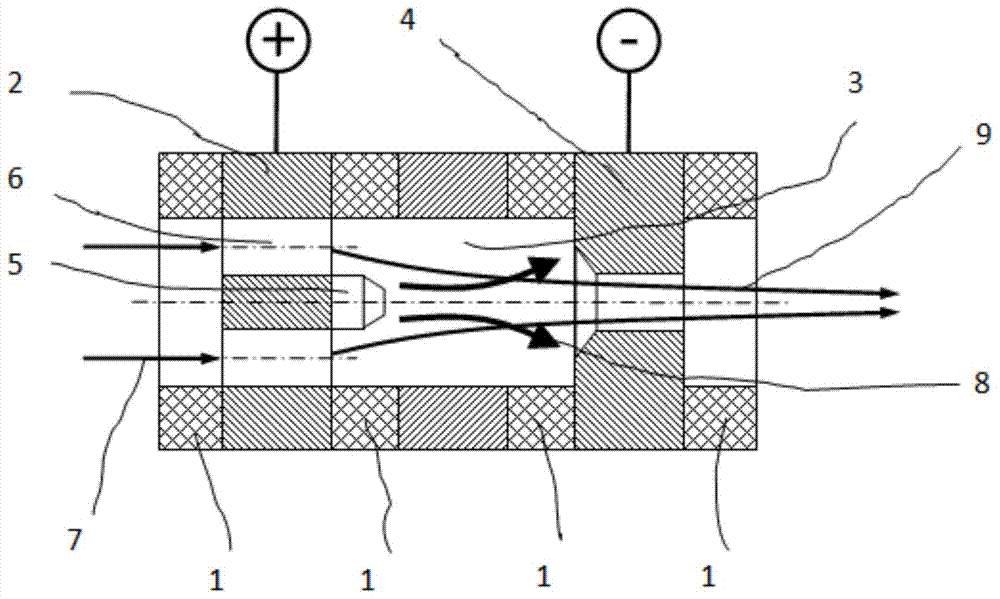

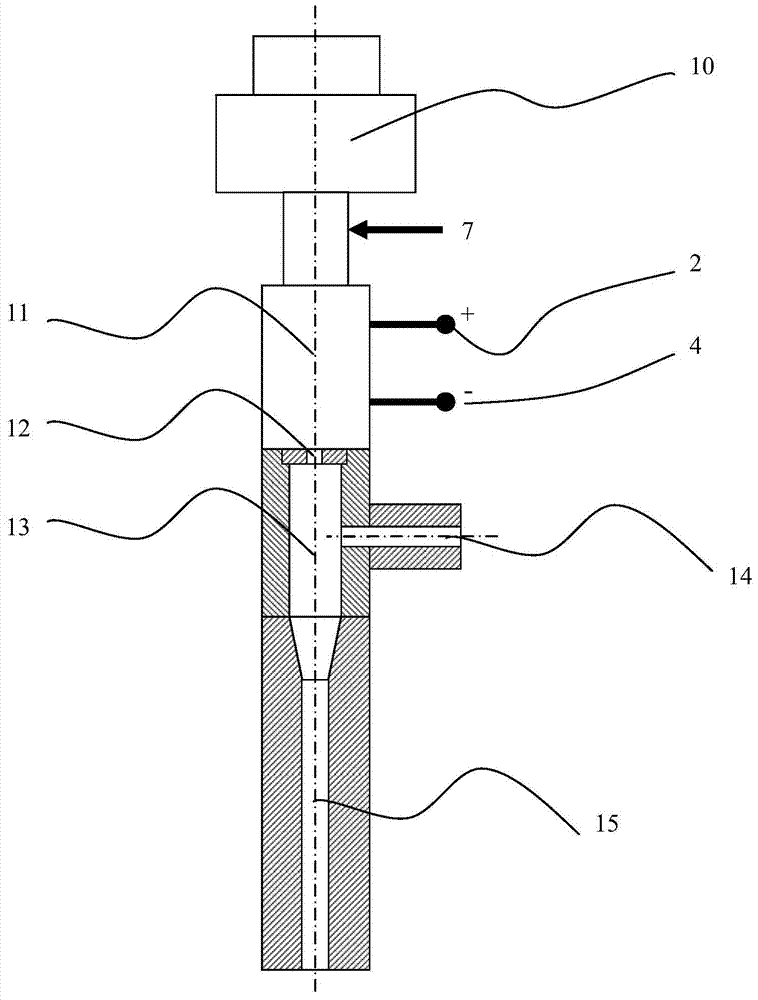

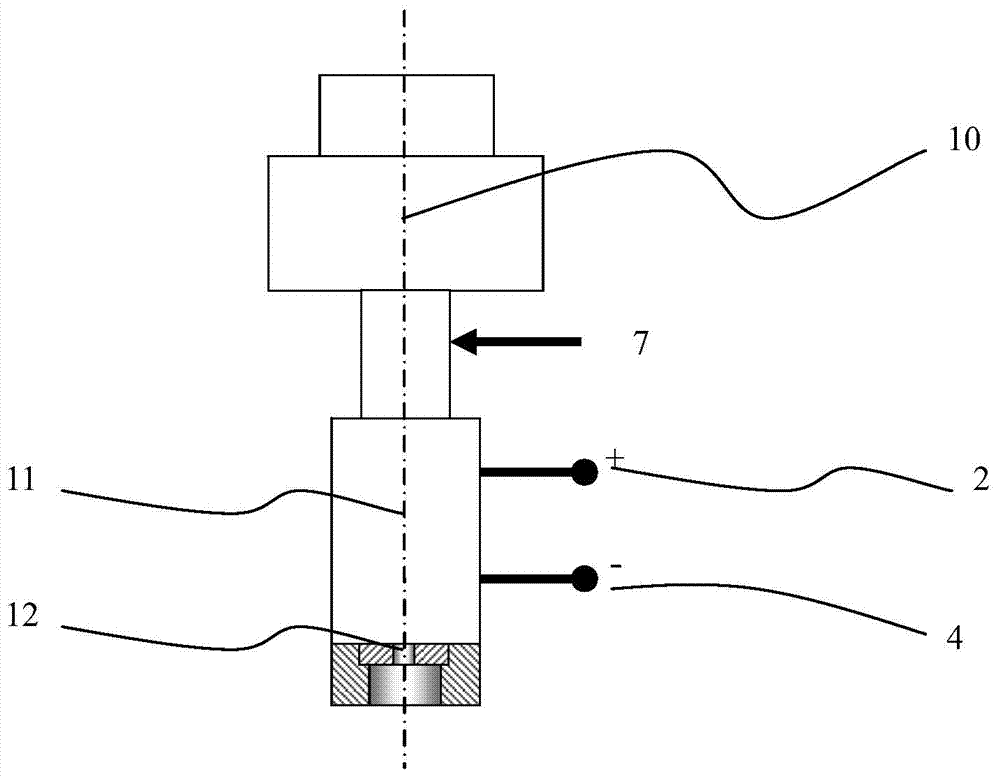

[0012] combine Figures 1 to 3 , The plasma subcritical / supercritical fluid generator 11 of the present invention is composed of a plurality of insulating sealing rings 1, protruding electrodes 2, chambers 3, and annular electrodes 4, and is characterized in that: the center of the protruding electrodes 1 has an electrode protrusion 5, There are holes 6 distributed along the circumference around the electrode protrusion 5, and the high-pressure fluid 7 flows in through the holes 6 distributed along the circumference on the protrusion electrode 2, and after being heated to a subcritical / supercritical state, it flows out from the center hole of the ring electrode 4, or The high-pressure fluid 7 flows in through the central hole of the ring electrode 4, and after being heated to a subcritical / supercritical state, it flows out from the holes 6 distributed along the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com