Distributing method for glazed ceramic tiles and equipment for implementing distributing method

A technology of ceramic bricks and ceramic powders, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of rough effects, etc., and achieve the effects of good shape stability, diversity, and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

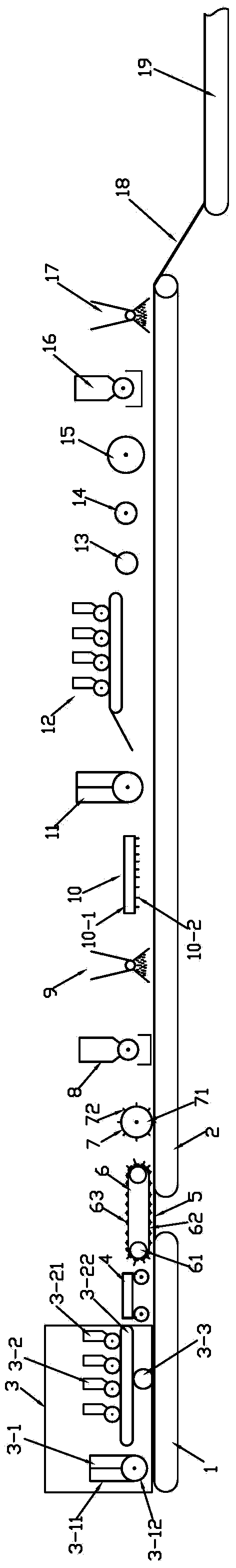

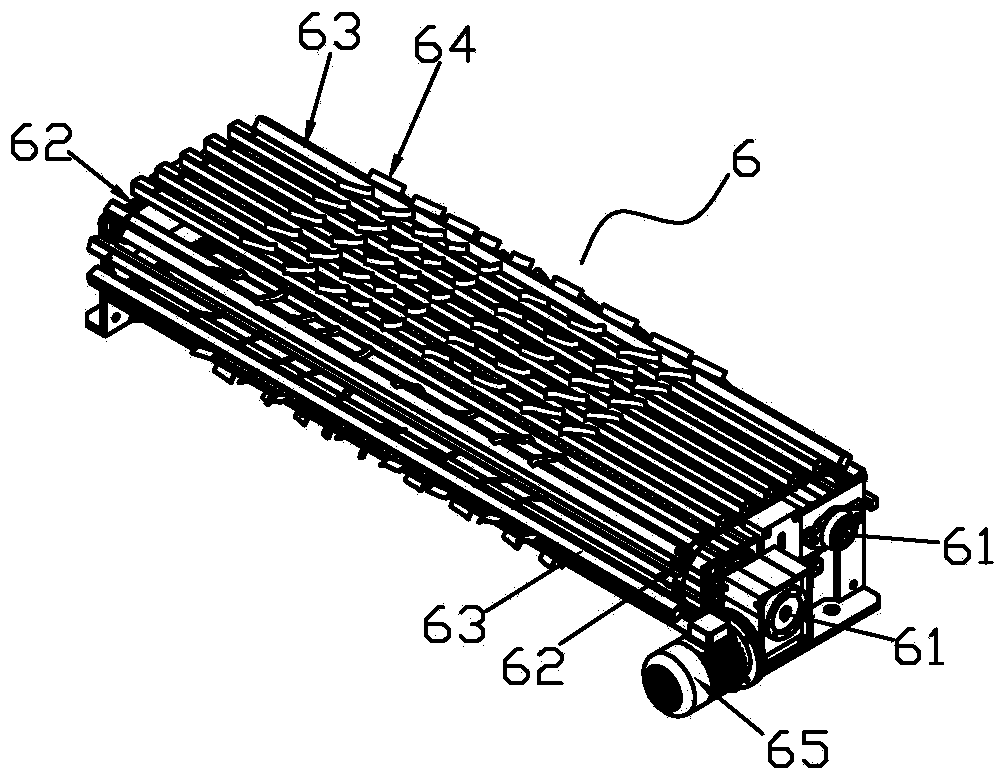

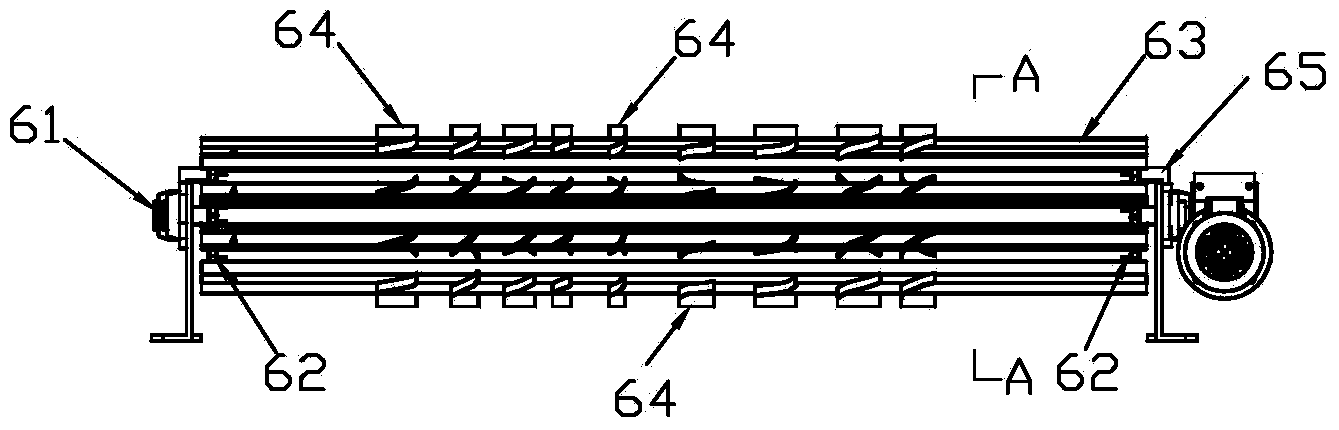

[0032] A method for distributing glazed ceramic tiles, the method steps are:

[0033] 1) After the lower cloth of the ceramic powder is pressed on the feeding belt and flattened into blocks, it is sent to the transition plate position between the feeding belt and another feeding belt through the feeding belt;

[0034] 2) Scrape the ceramic powder block into powders of various shapes and send them to another feeding belt;

[0035] 3) Prick out cracks of various shapes and sizes on the ceramic powder block in turn, and lay wire material and spray glaze slurry on the ceramic powder on the crack;

[0036] 4) Prick small cracks on the ceramic powder block again, and partially distribute a layer of ceramic powder with different thicknesses;

[0037] 5) Spread a thick layer of ceramic powder on the above ceramic powder, and sweep and compact it;

[0038] 6) Cutting the ceramic powder into shape, and re-laying the wire material and spraying the glaze slurry;

[0039] 7) Finally tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com