Locking device for hatch cover of deep-sea manned submersible

A manned submersible, locking device technology, applied in ship hatches/hatch, transportation and packaging, ship parts, etc., can solve the problems of endangering the safety of submersibles, cumbersome operation, difficult to ensure balanced locking force, etc. Achieve the effect of avoiding accidental unlocking, easy operation and reliable mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

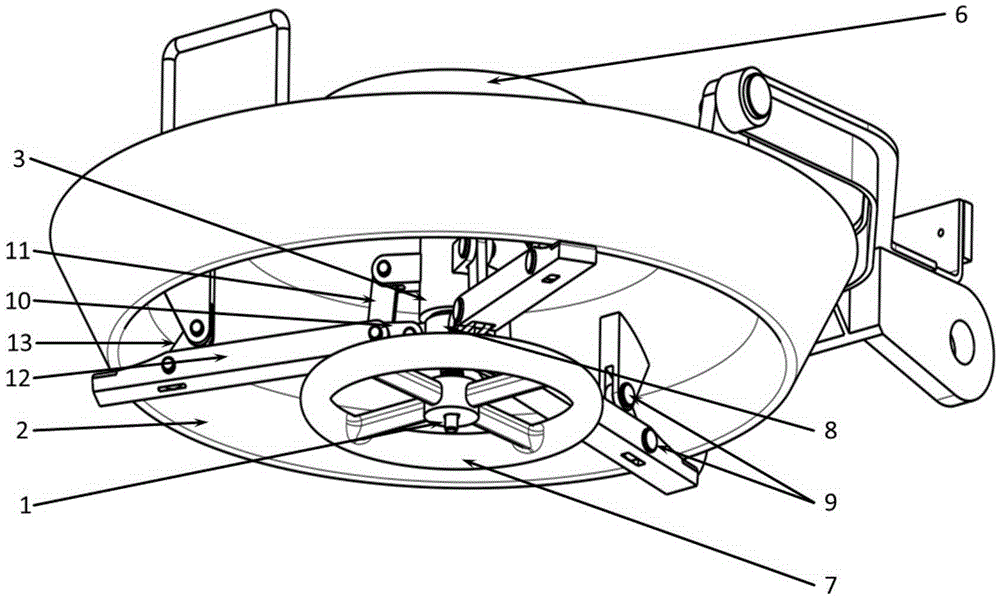

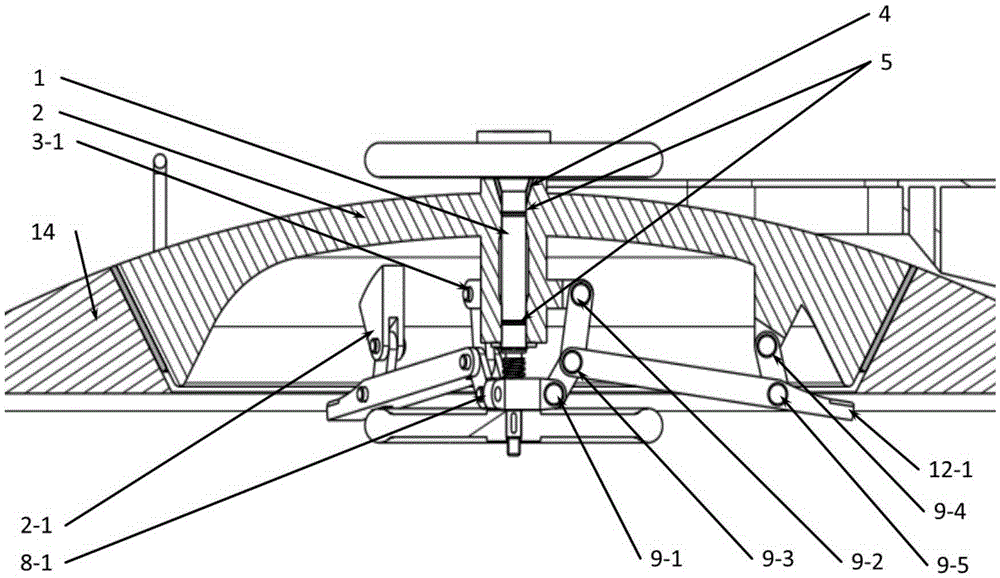

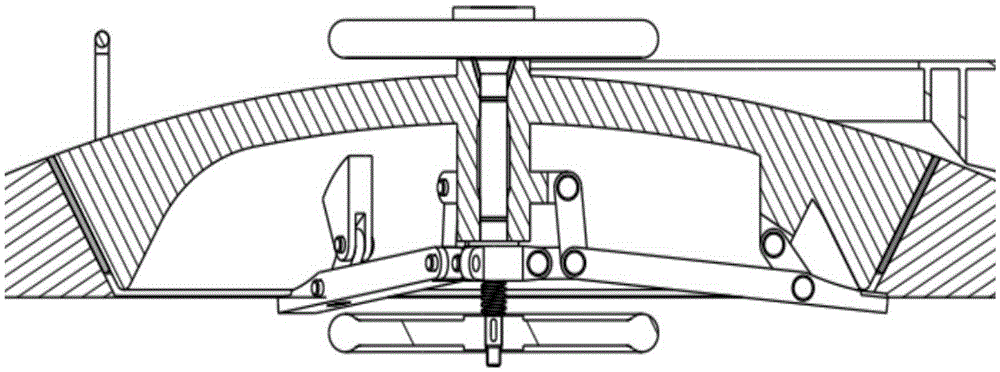

[0018] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] The basic composition of a hatch cover locking device of the present invention includes a rotating shaft passing through the hatch cover, a set of shaft sealing device, two rotating handwheels, a connecting rod system and matching traction nuts.

[0020] The penetrating rotating shaft 1 is a metal shaft penetrating the hatch cover 2. From top to bottom, it is the outer handwheel joint 1-1, the sealing tapered surface 1-2, two O-ring grooves 1-3, and the retaining ring. Groove 1-4, driving thread 1-5, keyway 1-6 and fastening thread 1-7. In order to prevent electrochemical corrosion, the through shaft is made of the same metal material as the hatch cover, and is treated with antirust.

[0021] The shaft sealing device includes a shaft sleeve 3 welded with the hatch cover, a truncated cone-shaped nylon ring 4 and two O-rings 5. In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com