Film for anti-glare glass

An anti-glare and film-attaching technology, which is applied to film/sheet adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem that the rubber surface is prone to reflection, unsatisfactory, and production efficiency reduction, etc. problems, achieve the effect of reducing the probability of absorbing dust and impurities, avoiding the generation of air bubbles, and avoiding serious losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

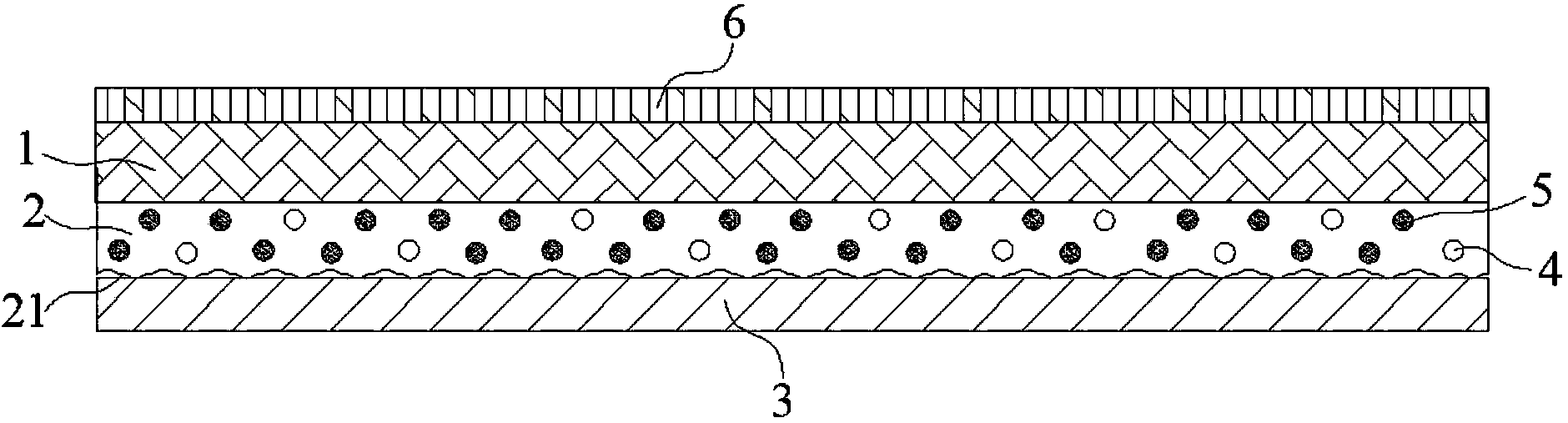

[0016] Embodiment 1: A kind of sticking film for anti-glare glass, comprising PET substrate film 1, this PET substrate film 1 upper surface has an antistatic coating 6, PET substrate film 1 lower surface is coated with a pressure-sensitive adhesive Layer 2, the other surface of the pressure-sensitive adhesive layer 2 is covered with a release material layer 3; several air holes 4 and thermally expandable microspheres 5 are evenly distributed in the pressure-sensitive adhesive layer 2; the pressure-sensitive adhesive layer 2 and The roughness of the contact surface 21 of the release material layer 3 is 3 μm to 3.1 μm; the above-mentioned thermally expandable microspheres can be thermally expandable microspheres of Akzonobel Company, and their elastic shells contain low-boiling substances such as isobutane, propane, and pentane.

[0017] The average diameter of the pores 4 is 6-6.2 μm; the average diameter of the thermally expandable microspheres 5 is 6-6.2 μm.

[0018] The pres...

Embodiment 2

[0019] Embodiment 2: A kind of sticking film for anti-glare glass, comprising PET base film 1, this PET base film 1 upper surface has an antistatic coating 6, PET base film 1 lower surface is coated with a pressure-sensitive adhesive Layer 2, the other surface of the pressure-sensitive adhesive layer 2 is covered with a release material layer 3; several air holes 4 and thermally expandable microspheres 5 are evenly distributed in the pressure-sensitive adhesive layer 2; the pressure-sensitive adhesive layer 2 and The roughness of the contact surface 21 of the release material layer 3 is 3.2 μm to 3.25 μm. The above-mentioned thermally expandable microspheres can be thermally expandable microspheres of akzonobel company, and its elastic shell contains isobutane, propane, pentane, etc. substance.

[0020] The average diameter of the pores 4 is 7-7.2 μm, and the average diameter of the thermally expandable microspheres 5 is 14-14.2 μm.

[0021] The pressure-sensitive adhesive la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com