Pressure-bearing type end-anchoring high-pretightening-force anchor rod support method

A bolt support and pre-tightening technology, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of limited prestress application, small length of free section, poor mechanical performance, etc., and achieve pre-tightening Increased force, convenient application of pre-tightening force, and guaranteed support performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

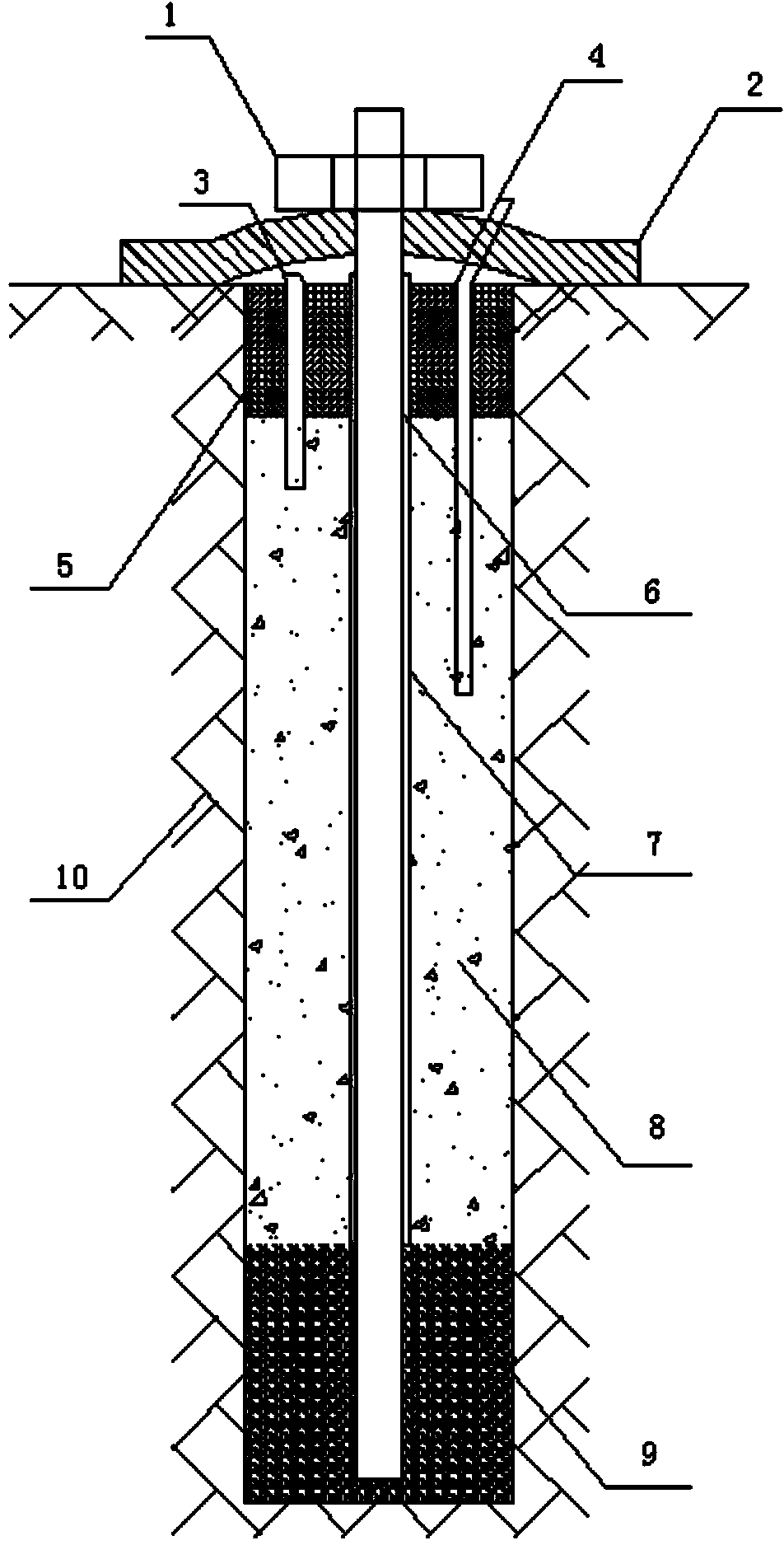

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0023] The concrete steps of the pressure-bearing type end anchor high pre-tightening force bolt support method of the present invention are as follows:

[0024] a. According to the surrounding rock conditions of the roadway and the requirements of stability control, design the pre-tightening force of the bolt, the anchor length of the end anchor section and the row spacing between the bolts, and drill 10 drills in the surrounding rock with a bolter at the design position according to the design parameters. Drill the bolt hole 8, and clean the bolt hole;

[0025] b. Install the end anchor resin anchor rod, and put the resin drug coil 9 into the hole according to the requirements; according to the designed end anchor length, first send the anchor rod 6 with the resin drug coil on the head into the constructed anchor rod drilling hole Carry out the end ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com