Air inlet pipe

An air intake pipe and air intake cavity technology, which is applied in the field of air intake pipes, can solve the problems of inconvenient processing, rough processing quality and high processing cost of the intake pipe, and achieve the effects of simple structure, high processing quality and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

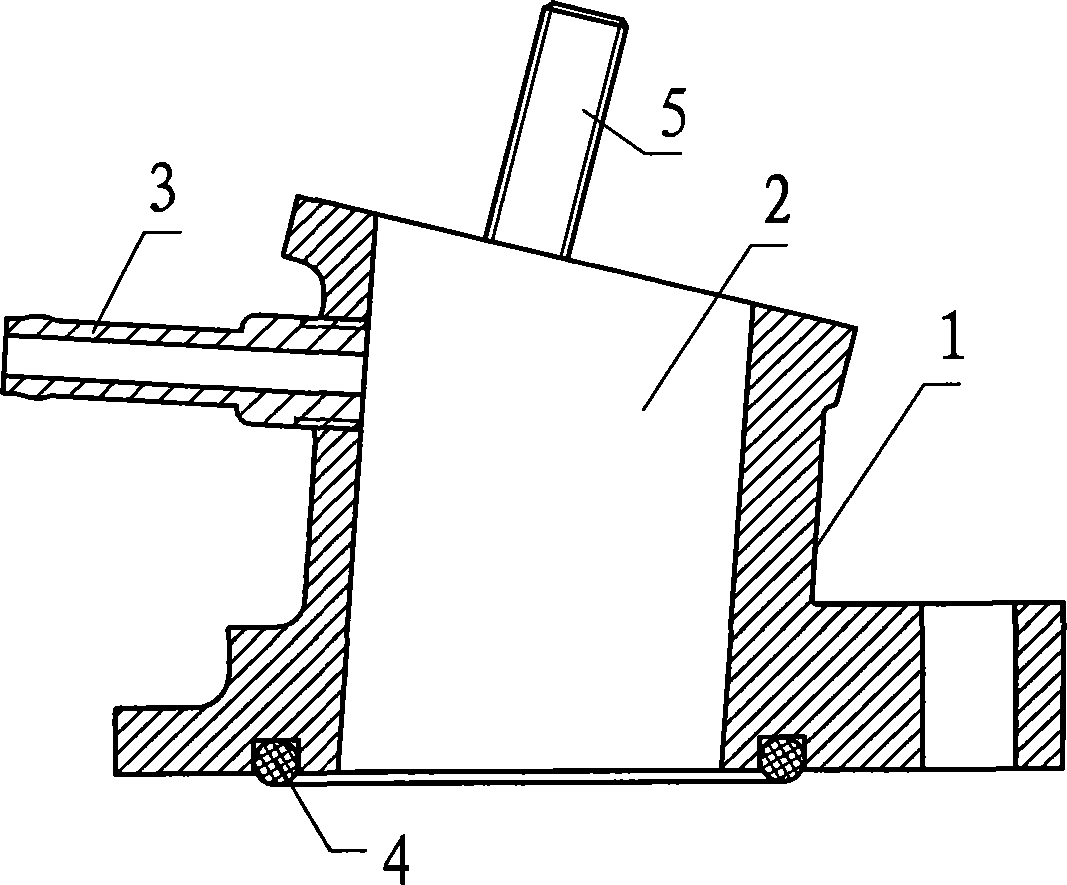

[0010] Such as figure 1 As shown, the intake pipe of the present invention includes the intake pipe aluminum alloy seat 1, the air intake chamber 2, the negative pressure nozzle 3, the O-shaped sealing ring 4 and the stud 5, and the stud 5 is located at the upper end of the intake pipe aluminum alloy 1 , the O-ring 4 is located at the lower end of the aluminum alloy seat 1 of the air intake pipe, the contour of the cross section of the inner wall of the air intake chamber 2 is a straight line, and the negative pressure nozzle 3 is installed on the aluminum alloy seat 1 of the air intake pipe and communicates with the air intake chamber 2 .

[0011] In the present invention, after setting the inner wall of the air intake chamber as a straight line, the internal structure is more favorable for processing, the processing cost is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com