Energy-saving pump driven by low-grade heat sources and based on phase change of working media and pump unit

A low-grade heat source, energy-saving pump technology, applied in the direction of pumps, pumps, machines/engines with flexible working elements, etc., can solve the problems of high cost, energy consumption and pollution, and achieve low cost, low pollution, and economical realization. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with each accompanying drawing, the present invention is described in detail.

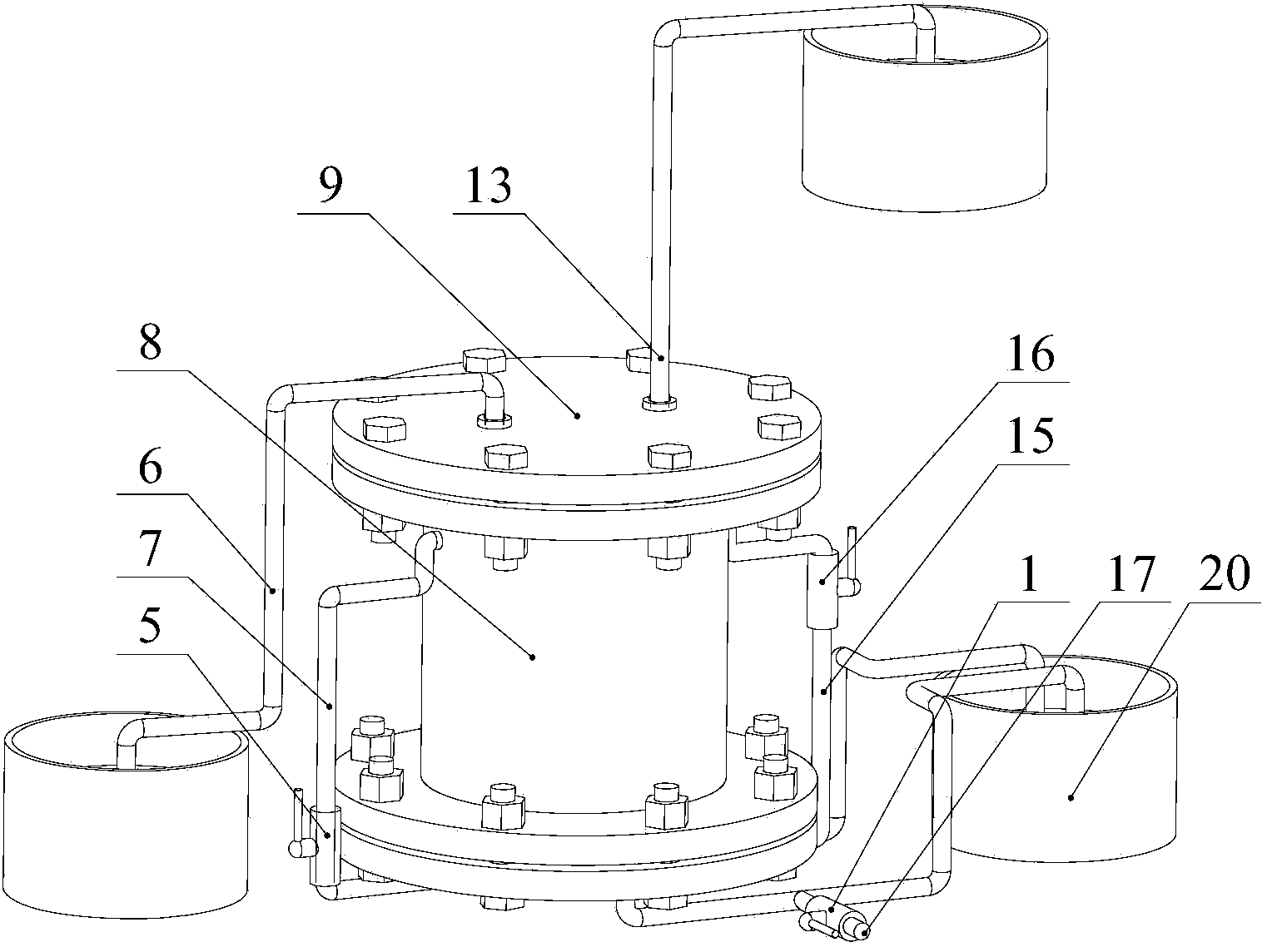

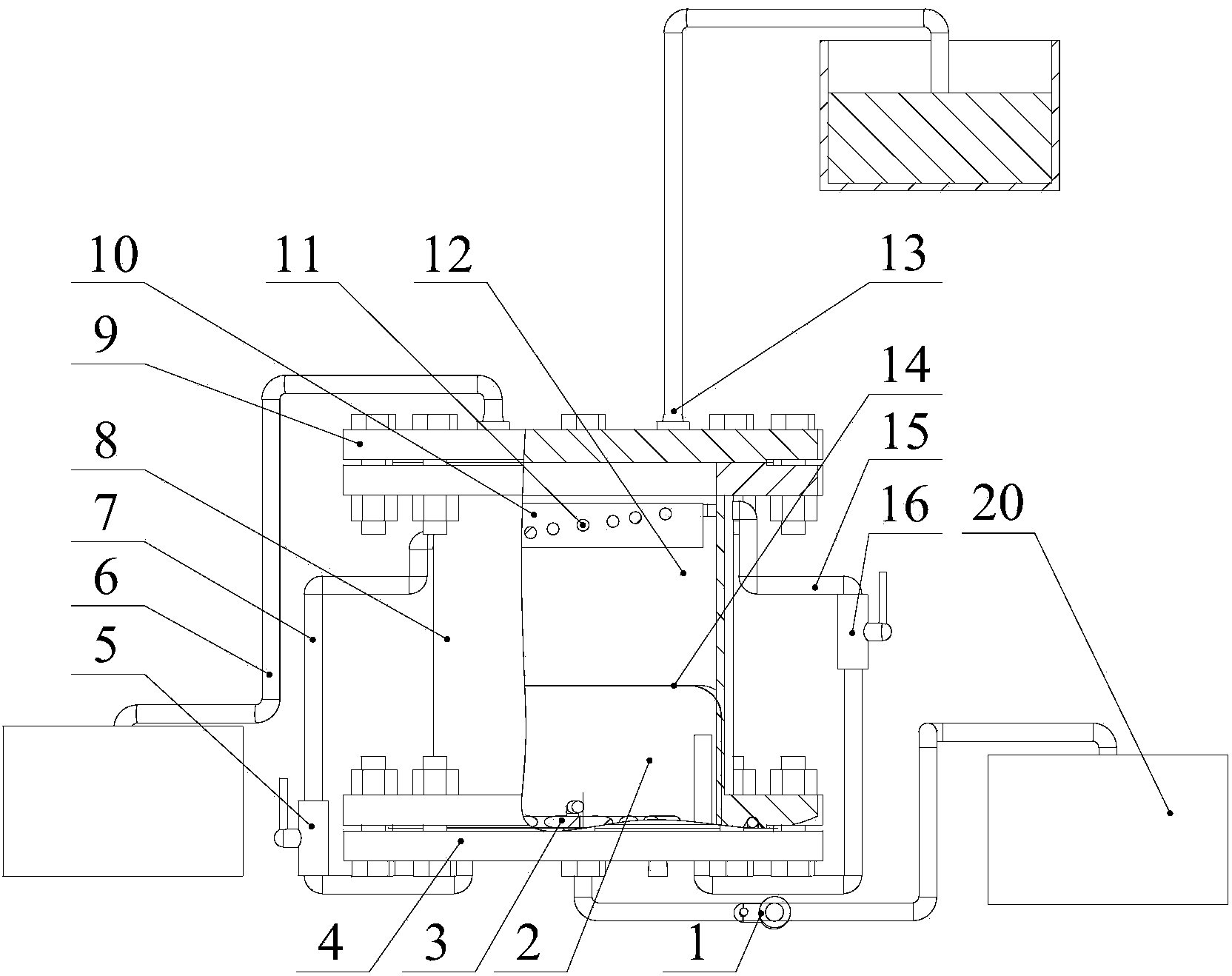

[0042] Such as figure 1 , 2 As shown, a low-grade heat source-driven energy-saving pump based on the phase change of working fluid, including:

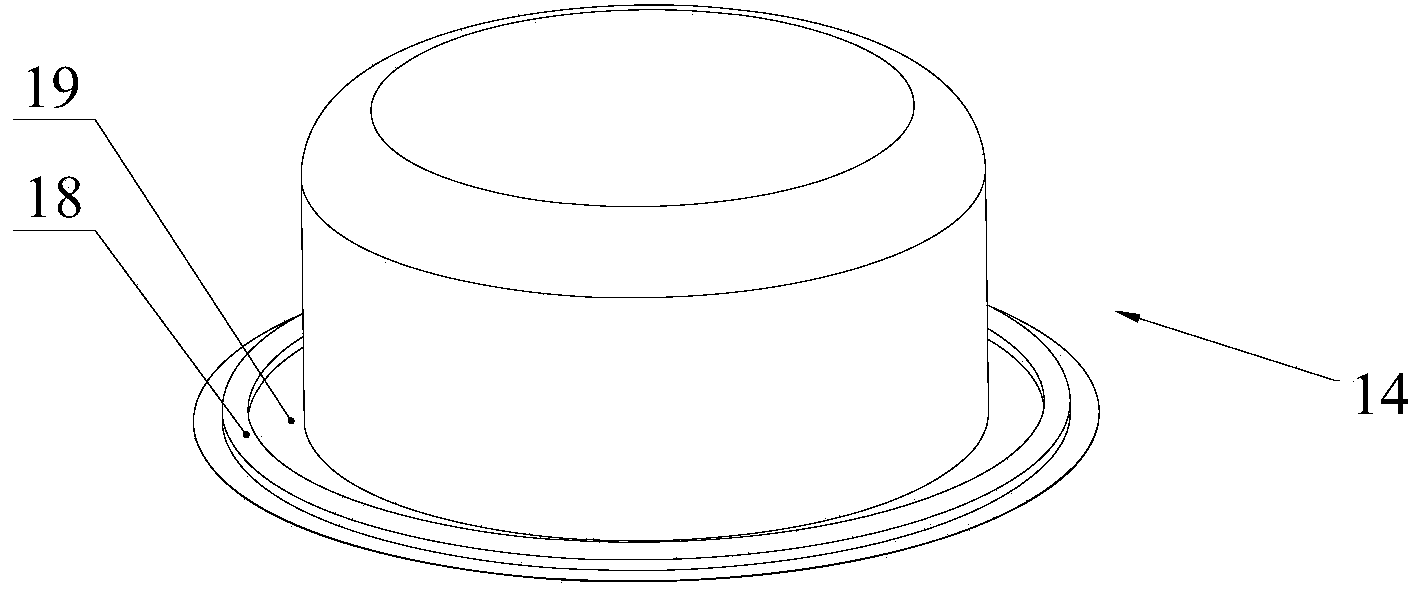

[0043]The pump casing is composed of a cylindrical casing 8 and an upper flange cover 9 and a lower flange cover 4 that are sealed at both ends of the casing; it is located in the casing 8 and divides the internal space of the pump casing into a power chamber 2 and an infusion chamber 12 The heat insulation film 14 of two parts; the heating coil 3 located in the power chamber 2 ; the condensation pipe 11 located in the infusion chamber 12 .

[0044] The infusion chamber 12 is respectively connected with a one-way liquid inlet pipe 6 and a one-way liquid outlet pipe 13, and the one-way liquid inlet pipe and the one-way liquid outlet pipe are respectively provided with a one-way valve, and the one-way flow is realized by setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com