Scanning laser vibration measurement system

A technology of vibration measurement and laser scanning, which is applied in the field of measurement systems, can solve problems such as being easily affected by ambient light, weak anti-interference ability, and poor anti-interference ability, and achieves convenient change of detection target area, firm and compact structure, and anti-interference ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

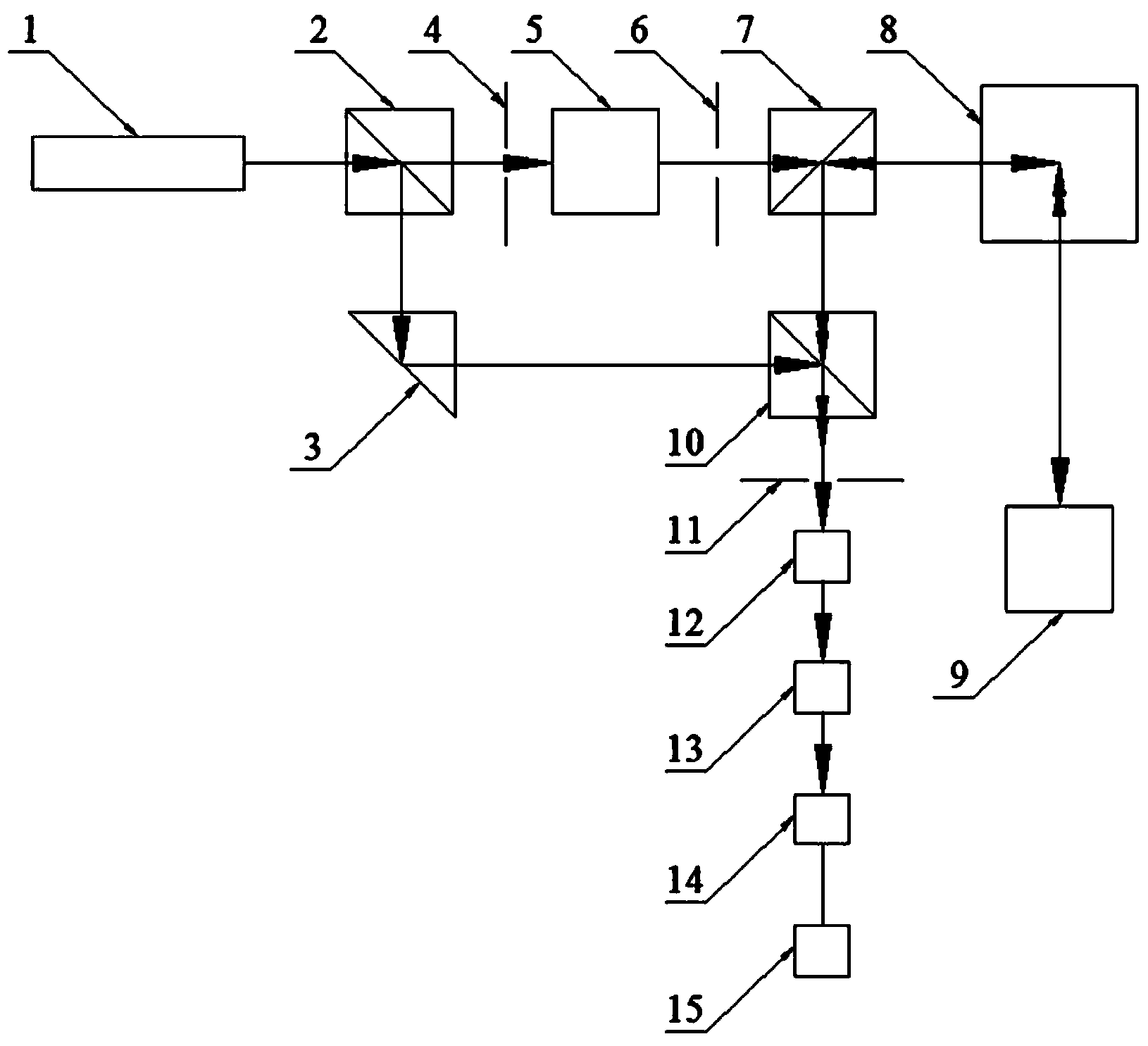

[0025] refer to figure 1 , The scanning laser vibration measurement system of the present invention comprises: a laser 1, a first dichroic prism 2, a reflective prism 3, a first diaphragm 4, an AO acousto-optic modulator 5, a second diaphragm 6, a second dichroic prism 7, two Dimensional scanning control system 8, beam combining mirror 10, third aperture 11, analyzer 12, photodetector 13, intermediate frequency amplifier 14 and signal processor 15, the laser beam is first divided into two beams in the system, and then combined, details as follows:

[0026] The laser 1 emits a laser beam, which is split by the first dichroic prism 2, and one of the beams is used as the local oscillator light of heterodyne detection and is reflected by the reflective prism 3 to the beam combining mirror 10 for beam combining;

[0027] The other light bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com