X-ray inspection machine and tire expanding rotation driving method thereof

A technology of rotary drive and rotary drive device, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems affecting the quality of inspection imaging images, achieve the effects of simplifying positioning and access methods, reducing deformation, and improving imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

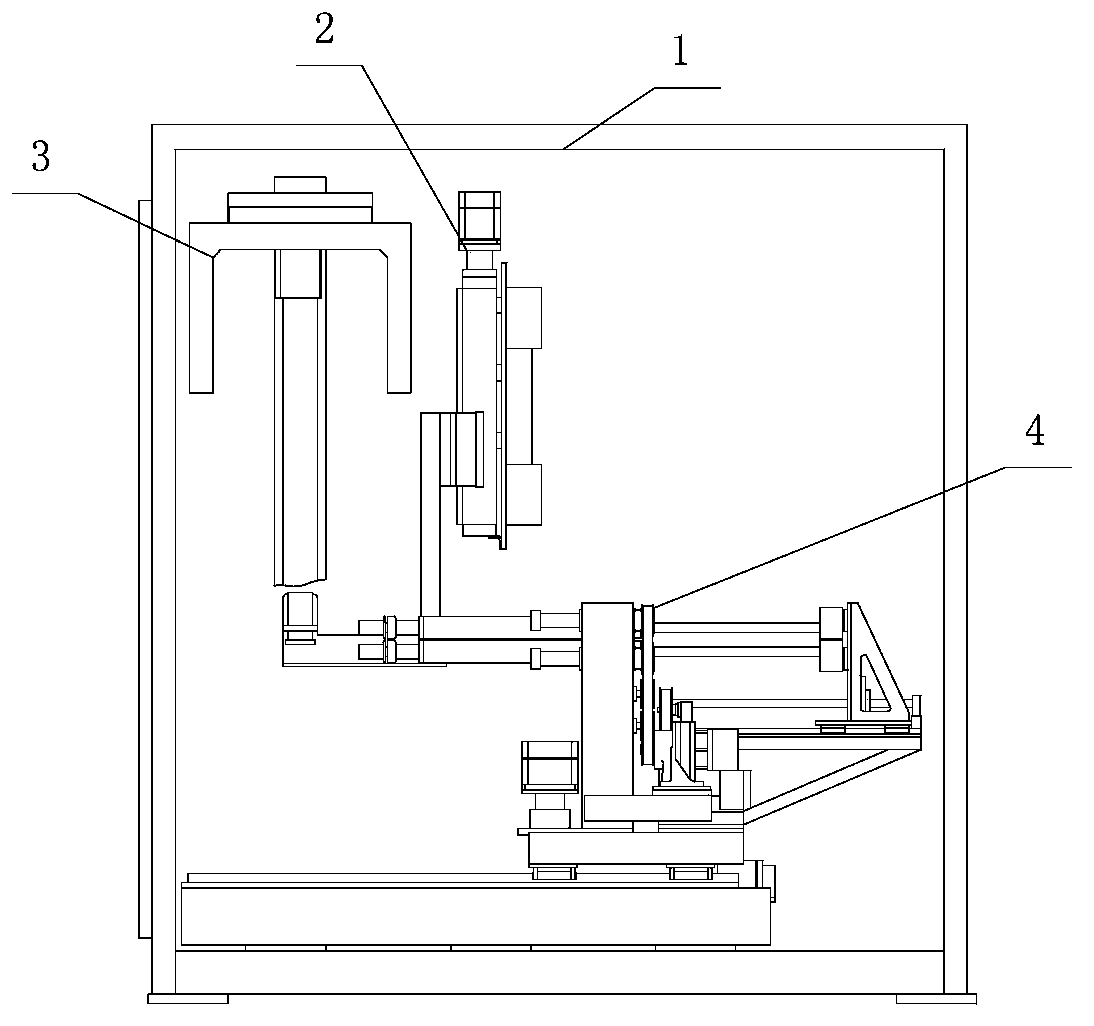

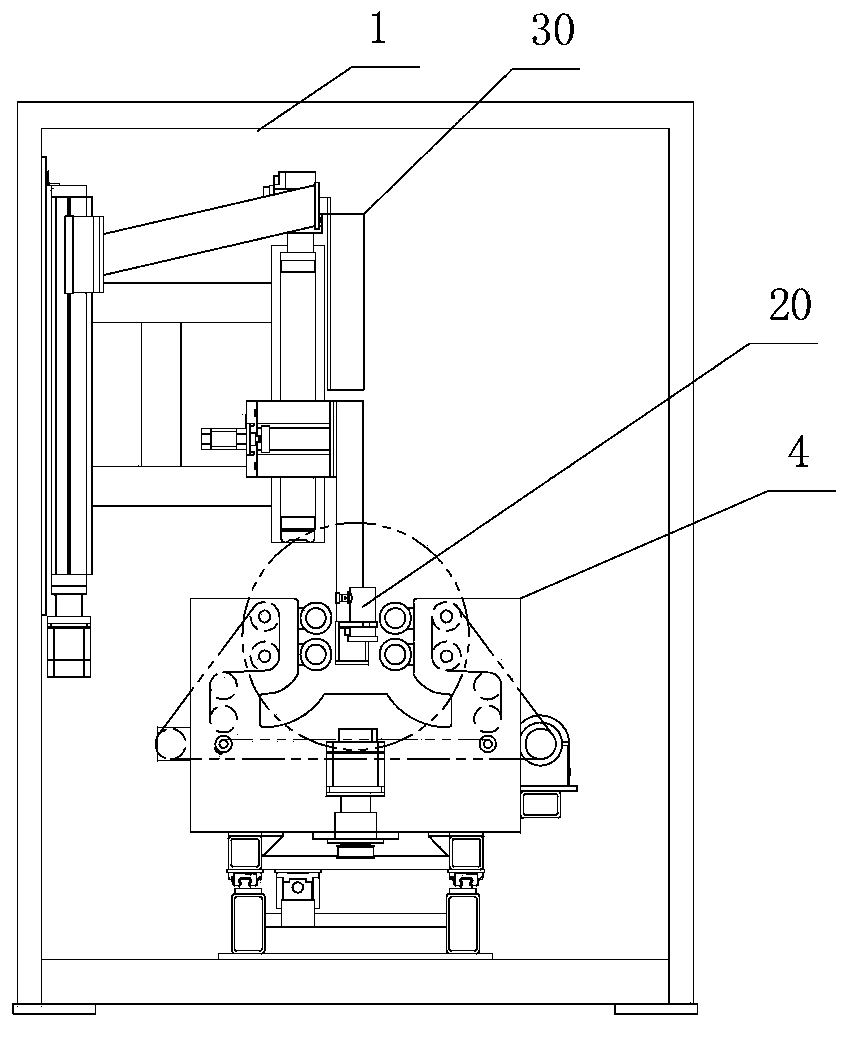

[0072] Example 1, such as Figure 1 to Figure 7 As shown, the X-ray inspection machine includes:

[0073] Lead room 1, used to provide a closed environment to detect tires;

[0074] The X-ray movement device 2 is used to transport the X-ray tube 20 to the tire mouth to emit X-rays;

[0075] The imaging system movement device 3 is used to transport the detector 30 to one side of the tire to receive X-rays and form an image;

[0076] The tire expanding rotation driving device 4 is used to carry the tire and drive the tire to rotate during the detection process, which includes,

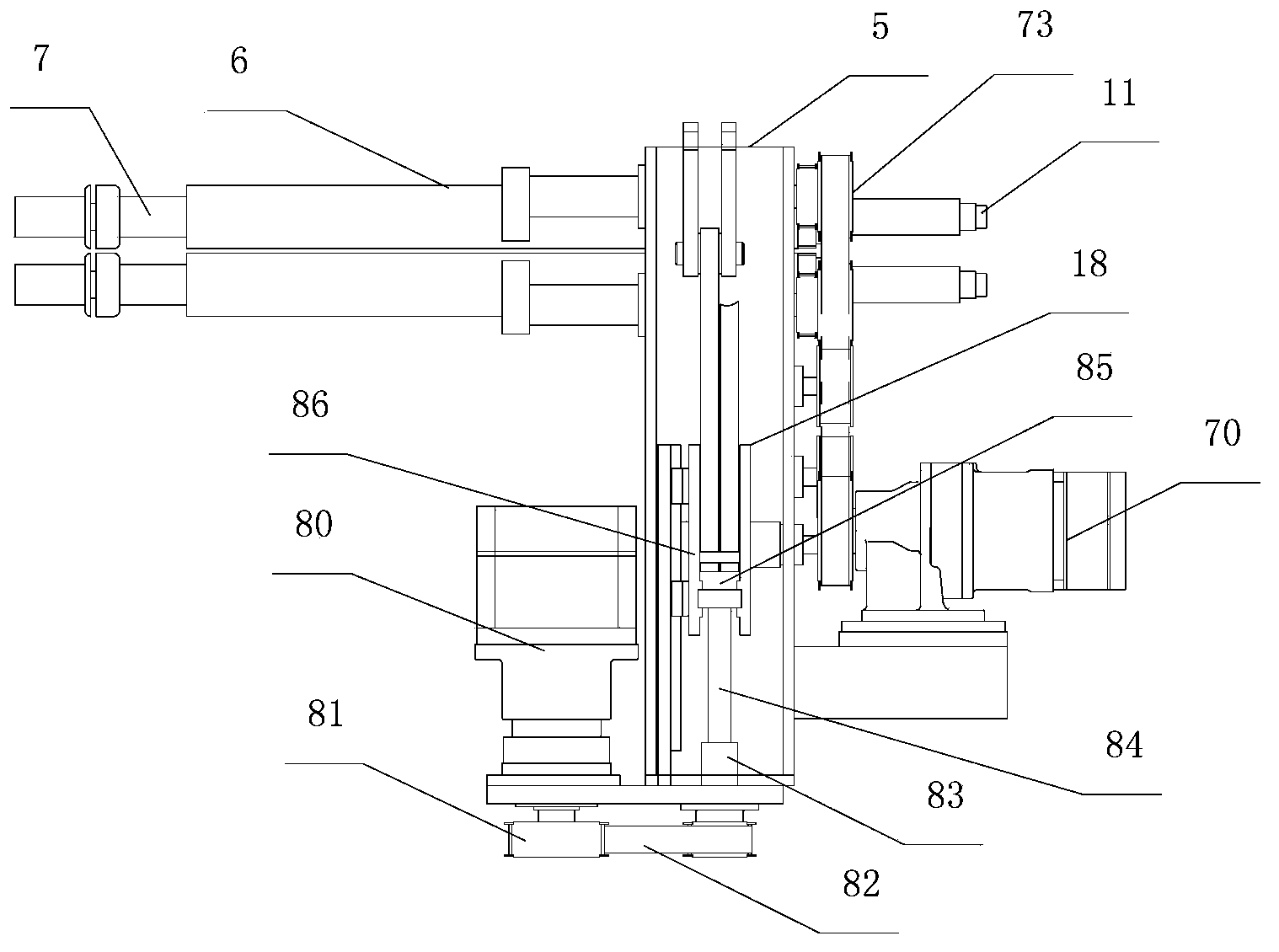

[0077] Frame 5, a support is fixed at the bottom of frame 5, guide rail is housed on the vertical surface of support, and following sliding frame 18 is fixed on the guide rail slide block;

[0078] 2 groups of guide rod bodies 6, the sides of which are symmetrically installed on the frame 5 through the mounting frame 10, and each group of conductor rods 6 is vertically distributed;

[0079] The guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com