Nondestructive evaluation method of stress of cladding layer based on critical refraction longitudinal wave

A critical refraction and evaluation method technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of destroying the integrity and performance of the sample, endangering the health of operators, and expensive testing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

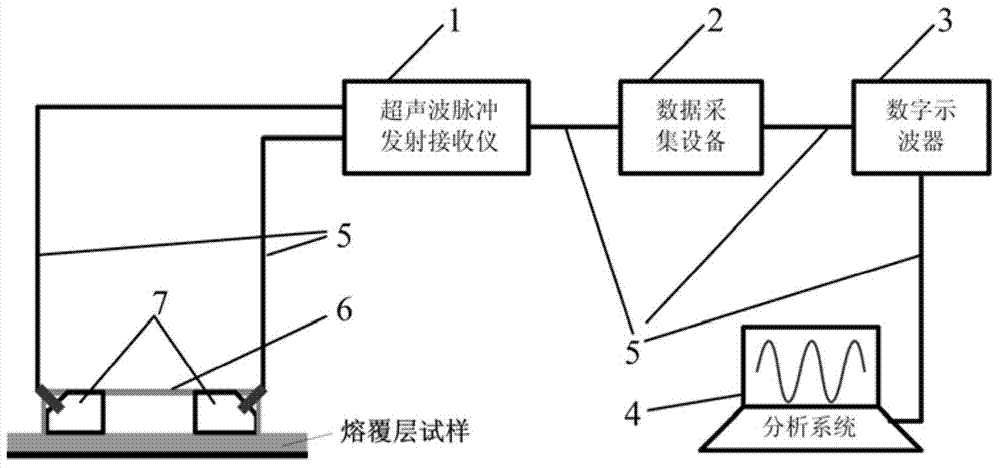

[0029] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following examples .

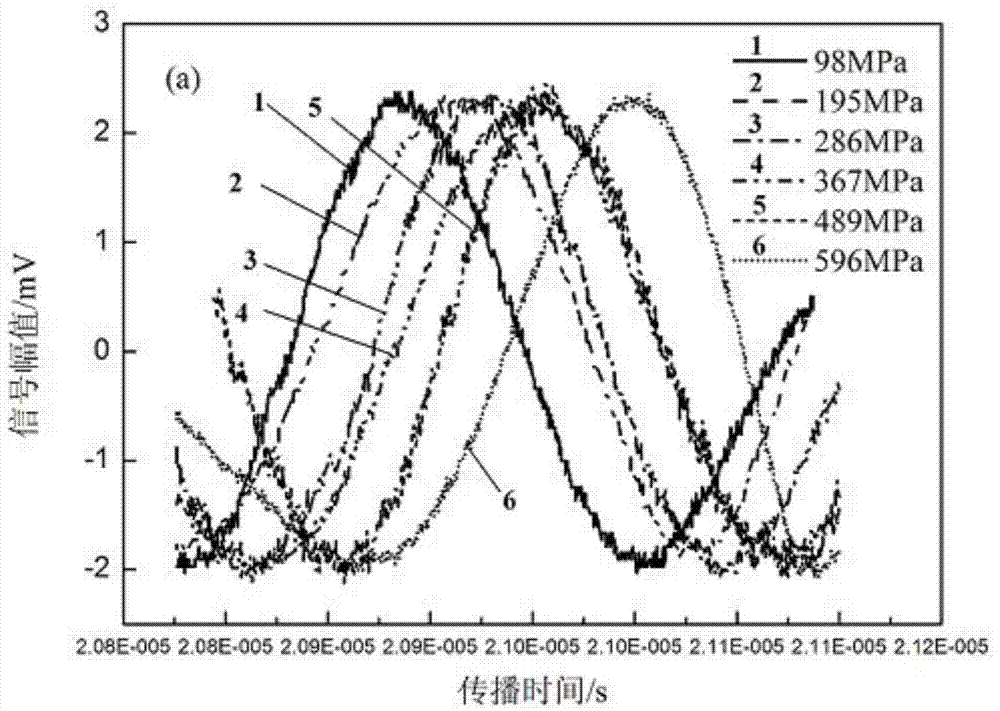

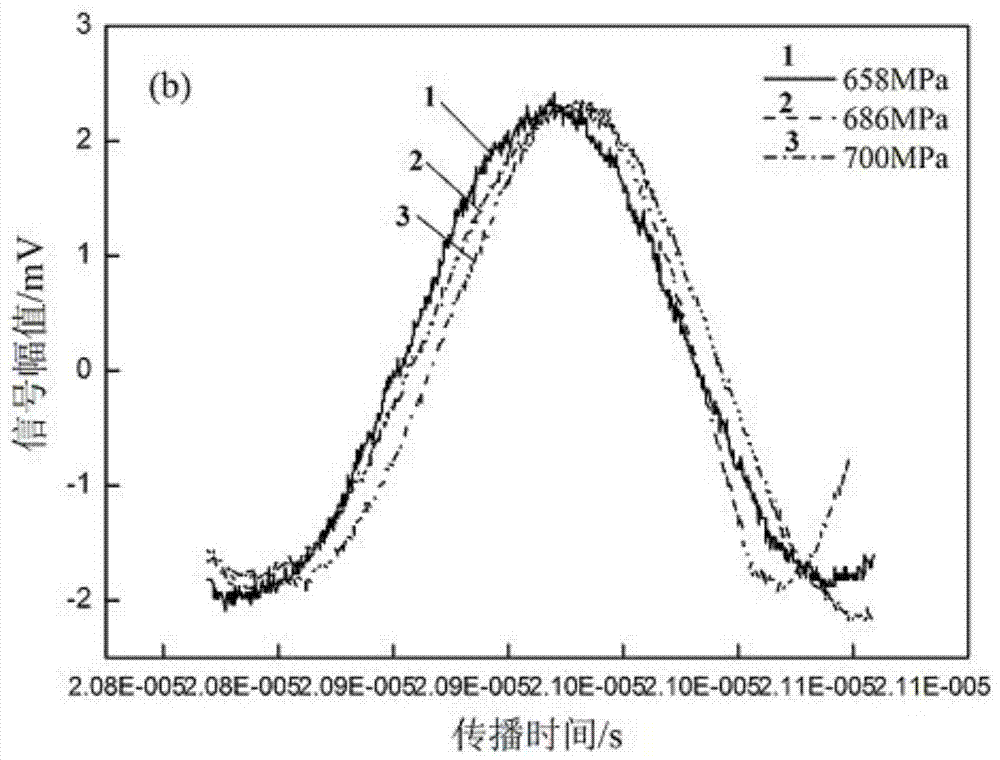

[0030] Selecting the Fe314 laser cladding layer on the surface of 45 steel as an example to describe the method of evaluating the stress of the cladding layer using critical refraction longitudinal waves, the corresponding relationship (stress-time difference curve) is obtained as follows:

[0031] 1. Using Fe314 alloy powder as the cladding powder, select the optimal laser cladding process parameters (cladding power, cladding speed, powder feeding amount), and use multi-layer lapping and multi-layer stacking to prepare a thickness greater than 45 on the surface of 45 steel. 5mm Fe314 laser cladding layer; main claddi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com