Outdoor ground drill rod used on percussion drill

A technology of grounding brazing and impact drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

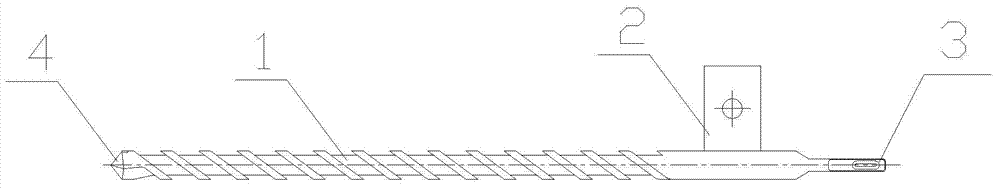

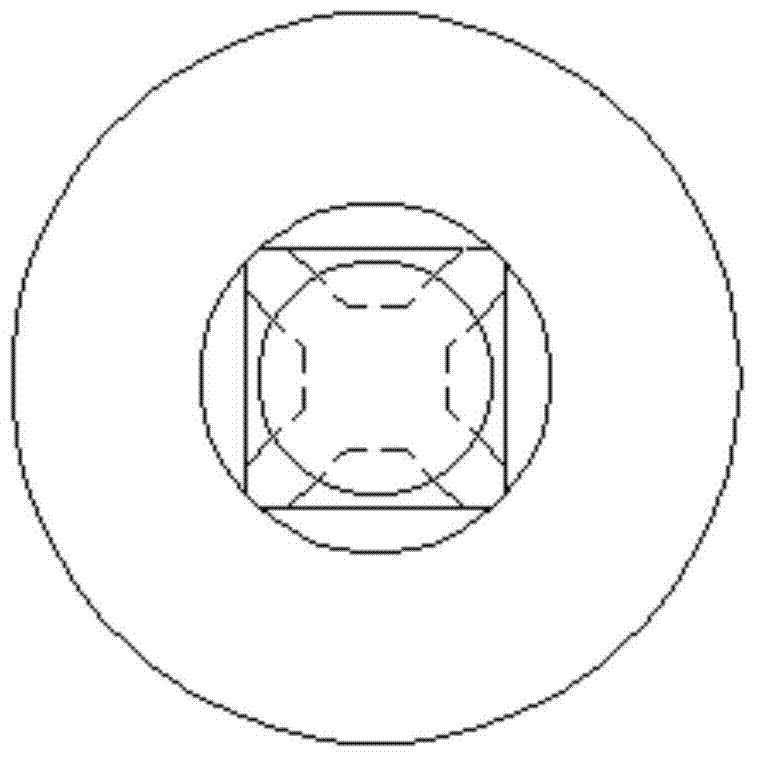

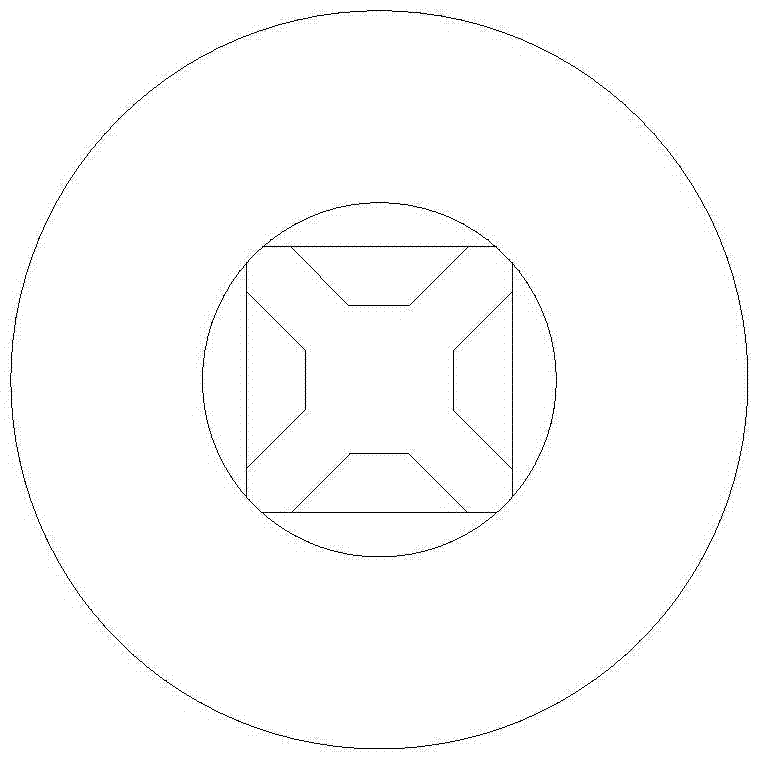

[0026] The length of the spiral part of the main body of the drill used in the present invention is 600mm, and the diameter of the drill is 16mm; the length of the drill clamp ground wire plate is 70mm, the width is 30mm, and the thickness is 3mm. The diameter of the fixed ground wire hole is 14mm. The keyway of the fixed brazing device is 55mm in length, 8mm in width, 28mm in length, and 7mm in width; the shape of the drill bit is diamond-shaped and made of alloy steel.

[0027] When in use, the main body 1 of the drill is installed on the impact drill, and the fixed drill device 3 is fixed inside the impact drill. The clamping ground wire device 2 is used to fix the ground wire, which is more convenient to use. The drill bit 4 is set in a rhombus shape, so that the impact drill It can save effort when working.

[0028] It is more suitable for the actual needs of construction sites in winter. It can be easily penetrated even in the deepest permafrost layer of 1.2 meters. It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com